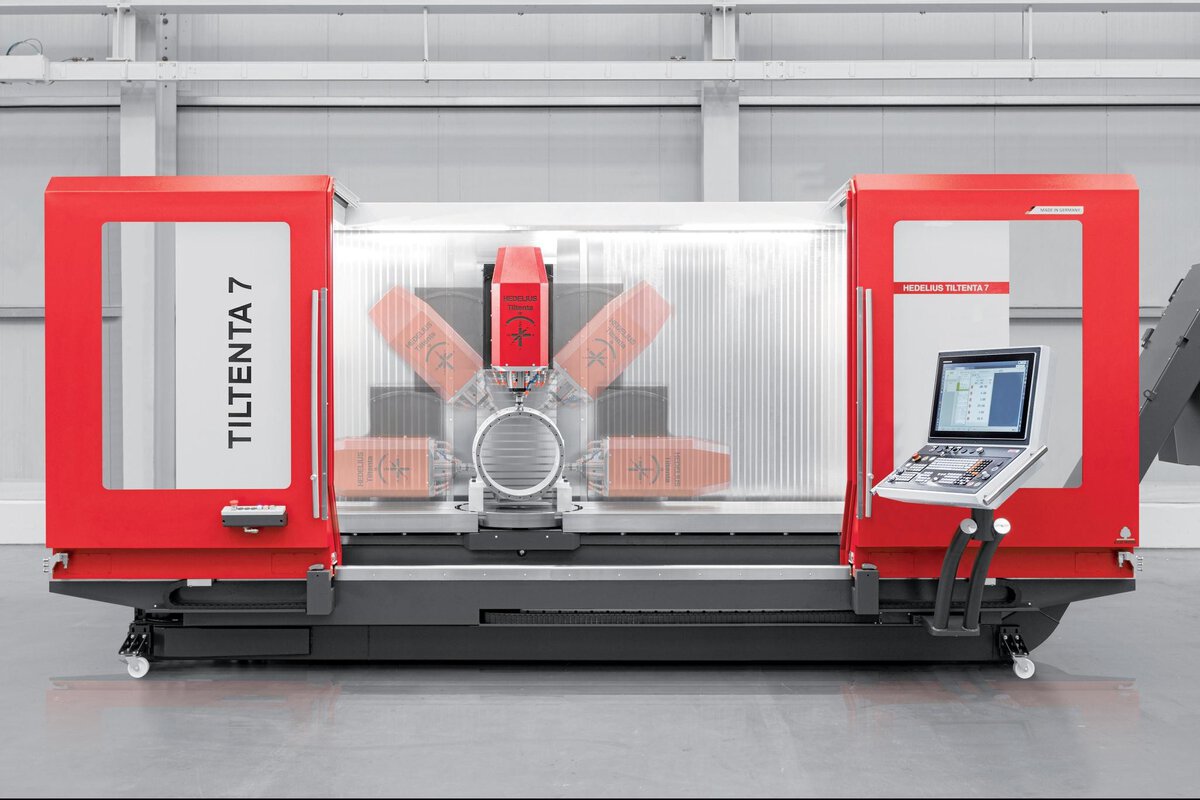

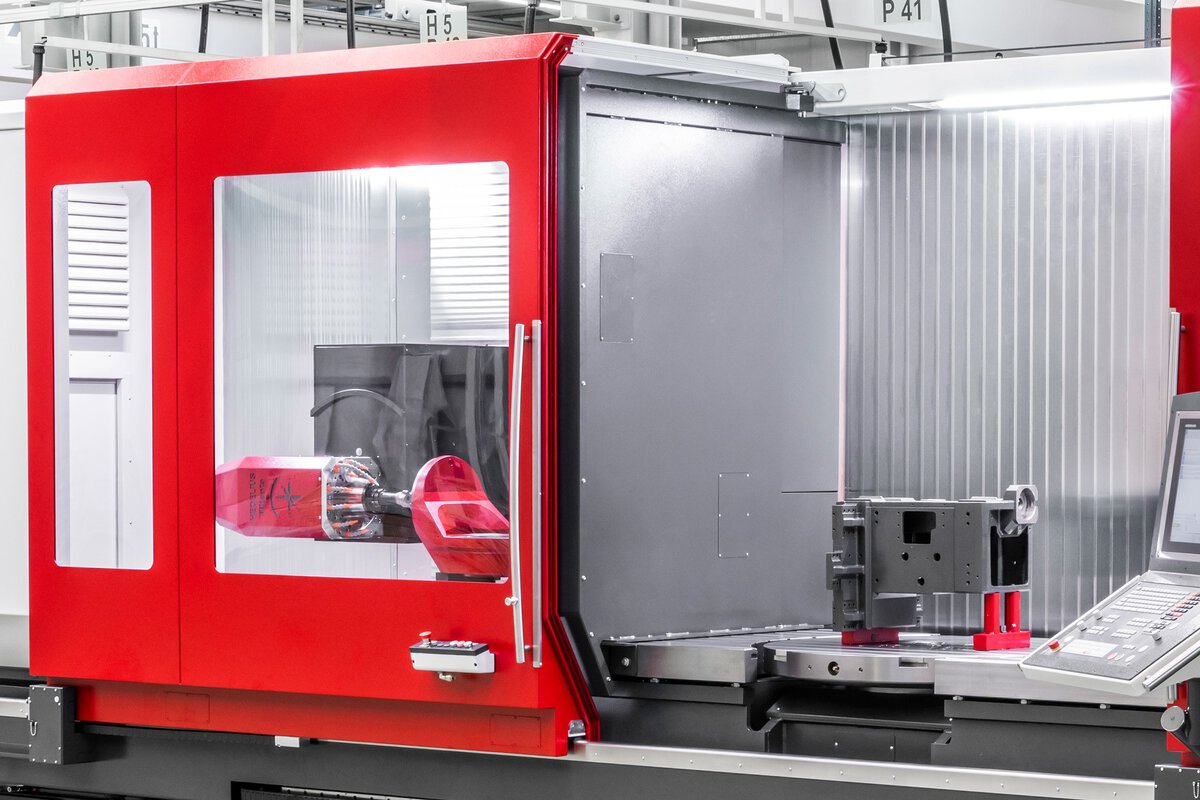

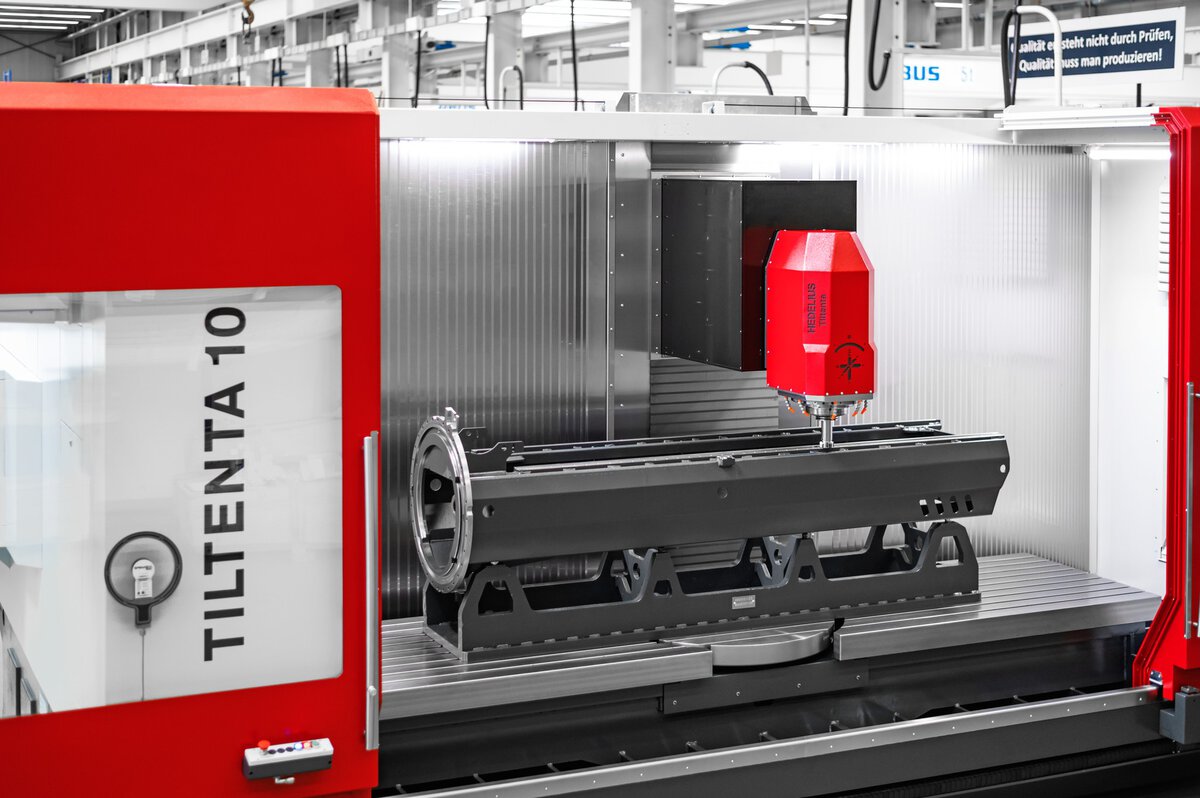

TILTENTA series: all-rounder for chipping.

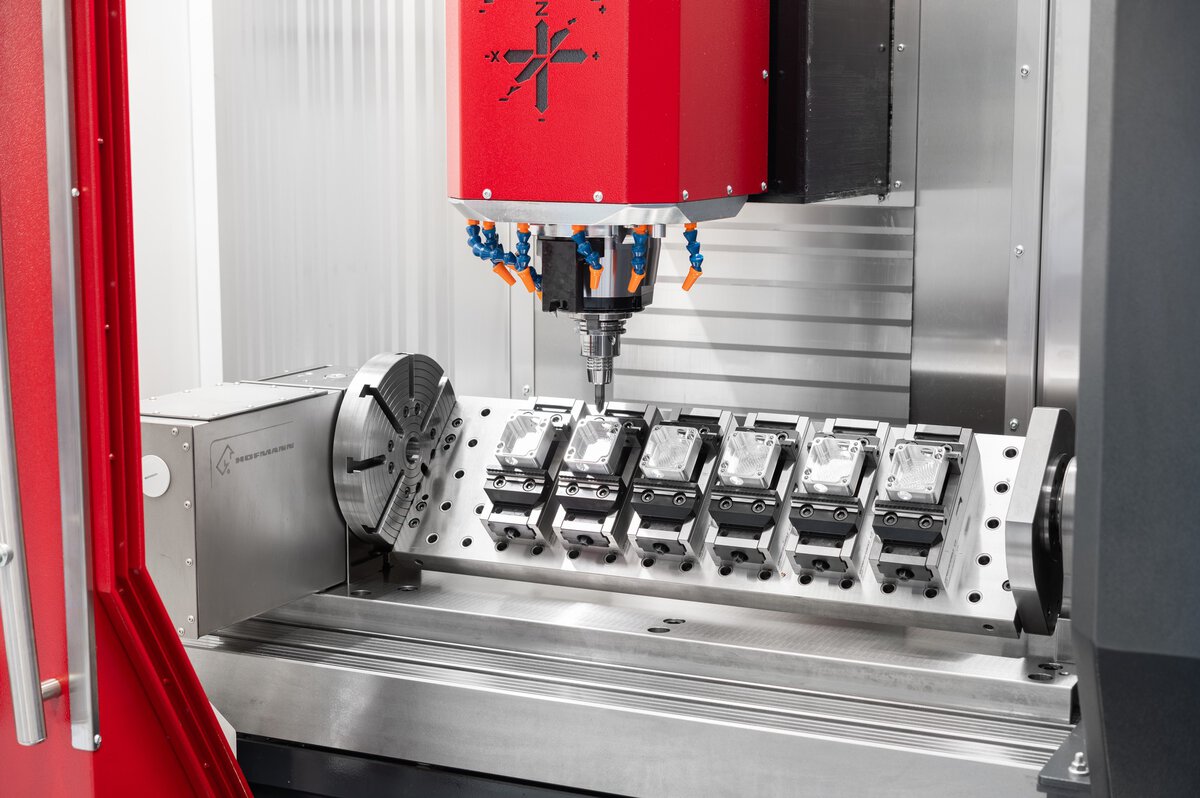

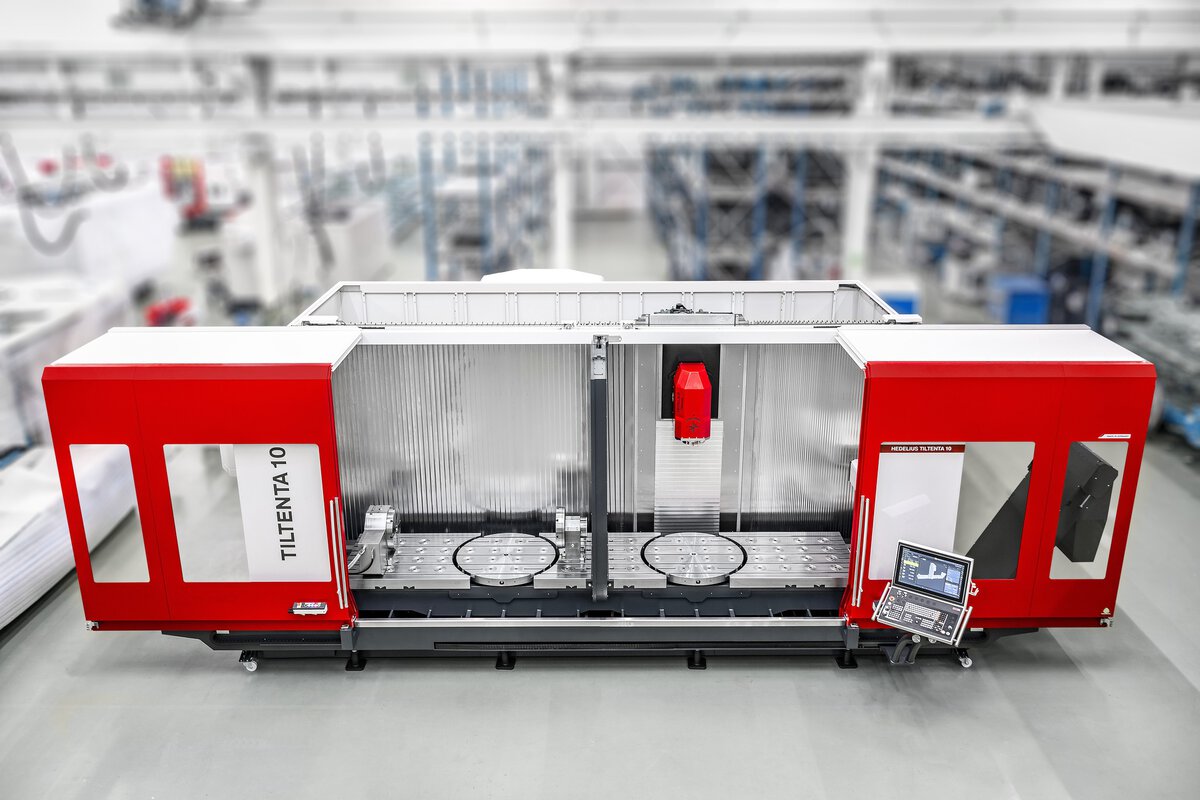

The high-performance machining centres in the TILTENTA series release many machining tasks in mechanical engineering, tool and mould making, shaft and roller machining and the aerospace industry. On the one hand, the large work area with the infinitely variable swivelling main spindle allows vertical machining of long workpieces up to 6000 kg. On the other hand, precise 5-sided machining of parts weighing up to 1800 kg in oscillation mode is also possible thanks to the integrated NC rotary table and a work area partition. The machining centres impress with vertical stainless steel covers for optimum chip fall and a fully encapsulated work area as standard.

MAXIMISE PRODUCTIVITY

WITH AUTOMATED

long-bed milling machines

5-axis and long part machining are ideal for single parts

and small series production. With automation solutions,

our customers can maximise the productivity of the

systems - for example, through automatic operation

in an additional shift or at weekends.

TILTENTA Series.

5-axis high-performance machining centre with infinitely variable swivelling main spindle.

Visit us at the

TECHNOLOGY CENTRE.

Experience the top performance of our CNC technology up close: We cordially invite you to visit our technology centre in Meppen and see the precision of our machining centres for yourself.

Reference reports from HEDELIUS customers.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

The finest optics in a clean room and modern milling technology under one roof: at VITRONIC in Wiesbaden, high-tech meets craftsmanship. The company develops intelligent image processing systems that are used worldwide in logistics, industry and transport. VITRONIC relies on the TILTENTA 7-2600 NEO from HEDELIUS for maximum precision in production. The machine impresses with its flexible processing of individual and small series, well thought-out design, generous installation space and the possibility of expansion through pallet automation. Find out more about the successful collaboration between VITRONIC and HEDELIUS in the case study.

Highest precision, modern production technologies and a partnership-based cooperation with customers from demanding industries - Fraune Metallbearbeitung GmbH & Co. KG from Delbrück in East Westphalia is committed to this quality promise. In 2022, the family business led by Managing Director Heinrich Fraune took the first step into automated production - with the compact 5-axis machining centre ACURA 65 and the multi-pallet storage system MARATHON SR422 from HEDELIUS.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

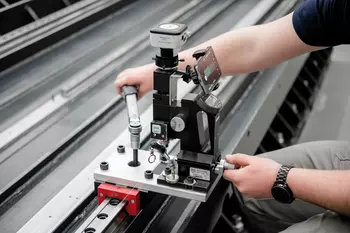

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.