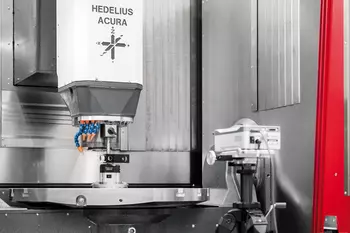

3-axis machining centre FORTE 50 Single 1120

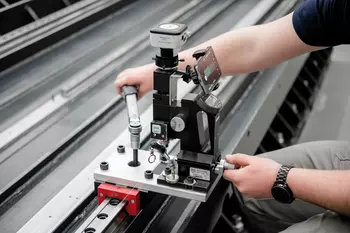

With the optional zero-point clamping systems, the tooling times of the FORTE 50 Single 1120 can be significantly reduced. This makes them a useful addition, especially for single parts through to medium series production. Other optional features include, for example, the 3D coordination of mould construction or the 3D infra-red measuring sensor for the automated scanning of workpieces and independent adjustment of machining specifications in the event of dimensional deviations.

Your advantages with the FORTE 50

- Generous X travel path of 1120 mm

- Large Z travel path of 550 mm

- Direct measuring systems as standard

- Fully enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Travelling column made from high-quality machine casting

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.