Progress through technology.

For more than three generations, HEDELIUS Maschinenfabrik GmbH has stood for highly developed technology in economical chipping. Our powerful CNC machine tools from northern Germany are in use throughout Europe. With over 3,000 HEDELIUS machining centres installed, we now ensure precise and powerful chipping in a wide range of industries.

Precision forms the basis of each of our machining centres. Our CNC solutions are characterised by numerous technical highlights that make our machines particularly efficient.

All machining centres from the HEDELIUS end program are developed and optimised with a clear goal in mind: they should be perfectly open to the needs of the user. A wide pallet of technical possibilities for tooling optimisation and numerous other optional features enable us to achieve this goal in the long term.

Accuracy of HEDELIUS machining centres.

Precision is central to HEDELIUS CNC machining centres, as it ensures exact and repeatable production results. Our machining centres are designed to produce complex workpieces with minimal tolerances, which is particularly essential in demanding industries such as air and space travel or mechanical engineering. The high precision of HEDELIUS machines increases product quality and minimises rejects. In addition, precisely manufactured machines contribute to the longevity and reliability of manufacturing processes, which reduces costs in the long term and increases your competitiveness.

Sophisticated type.

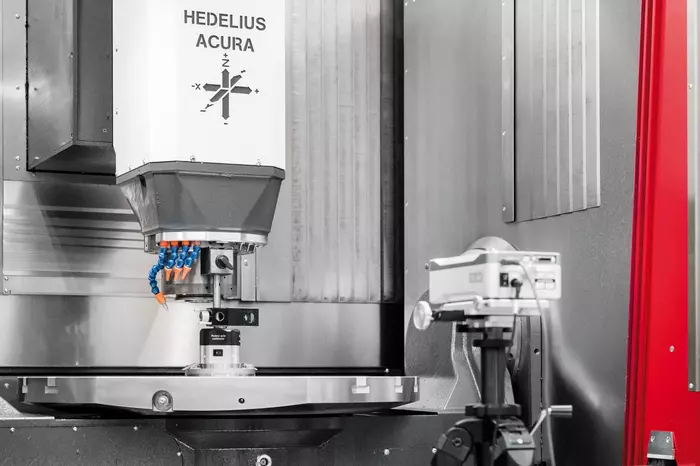

Designed as universal machining centres for a wide range of applications in machine and tool construction, HEDELIUS places great weight on stability and accuracy during the design phase. The result of this process was the special HEDELIUS type with the constantly cantilevered Y-axis and the resulting high rigidity and precision over the entire travel range of the Y-axis and Z-axis.

Long-term precision.

HEDELIUS only uses direct linear measurement devices for position detection of the X-axis, Y-axis and Z-axis. This means that the position control loop encompasses the entire feed mechanism. This is referred to as "closed loop" operation. Transmission errors in the mechanics can thus be detected by the linear measurement device on the feed axis and corrected by the control electronics.

In-house production.

Critical assemblies such as travelling columns, beds and rotating/swivelling table units are manufactured and measured in-house at HEDELIUS. As a result, we not only always keep an eye on quality, but also recognise the possibilities and limits of modern chipping in day-to-day use. This process knowledge flows permanently into improving our products and advising our customers.

Guides and straightness.

HEDELIUS uses pre-aligned roller guides from German and Swiss manufacturers. At the end of assembly, the positioning precision, repeat precision, straightness and backlash of the linear axes are finally checked and documented using a laser interferometer. The positioning accuracy of the linear axes in accordance with ISO 230-2 is regularly less than 6 µm.

Measuring systems on round axes.

The accuracy of the measuring systems has a significant influence on the angularity and parallelism of surfaces and bores. HEDELIUS uses direct angle encoders in the centre of each rotational axis in the integrated rotary tables, the swivel spindle drives and the rotating/swivelling table units. As an option, laser-based angle measurement devices measure the positioning accuracy of rotational axes with a resolution of ±1" and calibrate the axes for maximum positioning accuracy.

IT6 circular accuracy.

The Renishaw circularity test has established itself as a test method for the accuracy of machining centres. The measurement provides information on the interaction between two linear axes and the accuracy of a circular movement. The slip-stick-free roller guides in combination with direct path measuring systems and high angular accuracy enable the milling of fits in a quality of IT6, which reduces production times and the number of spindle tools required.

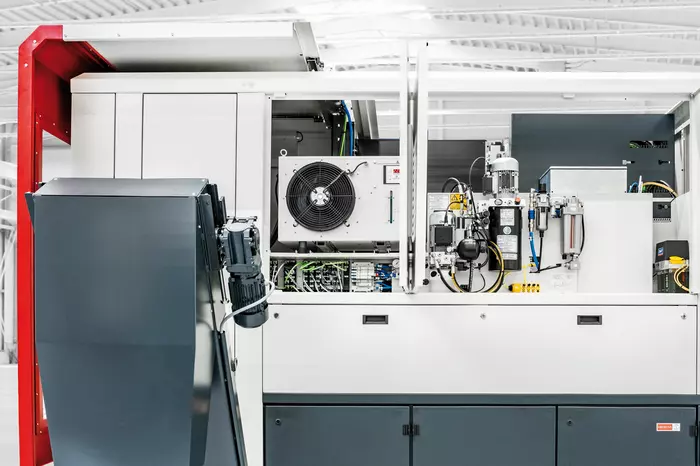

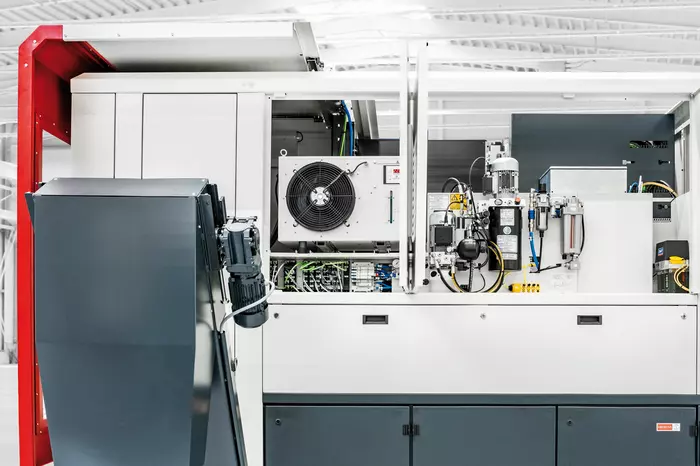

Temperature compensation.

HEDELIUS equips its machining centres with spindle coolers to dissipate the heat generated in the milling spindle. The cooling system already achieves increased thermal stability as standard. However, as not all of the heat can be dissipated by the spindle cooling, HEDELIUS optionally installs temperature sensors on the spindle, travelling column and, in some cases, on the rotary axes in order to compensate for structural displacements via the control system.

The chips of our machining centres.

For over 55 years, HEDELIUS machining centres have stood for state-of-the-art technology and engineering excellence. Our many years of expertise are reflected in the design of our machines. Various design highlights ensure that our customers can achieve maximum precision and efficiency in every production step.

Fully encapsulated work area

The work areas of the CNC milling machines are fully enclosed as standard. If a connection to a central coolant extraction system is not possible, the machines can be optionally equipped with a stationary oil mist extraction system.

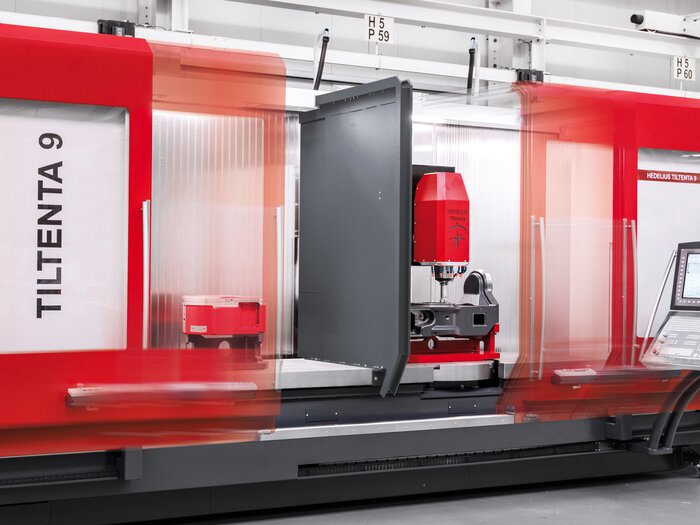

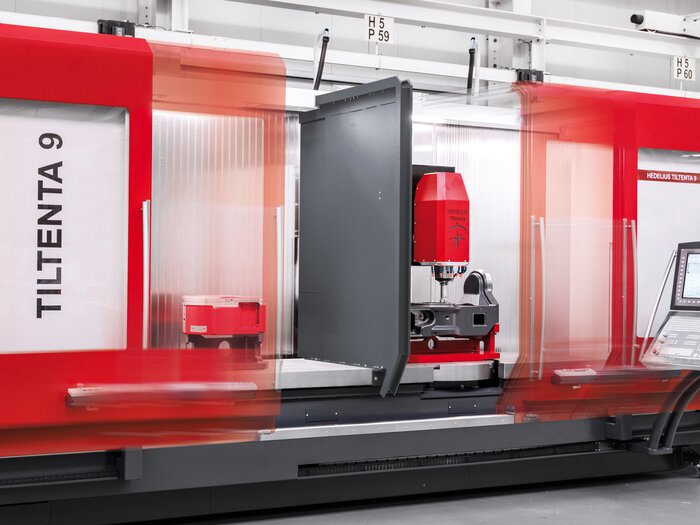

Infinitely variable swivelling main spindle

The TILTENTA machining centres have a continuously variable swivelling main spindle as an NC-controlled B axis ex factory. The swivelling gear is a backlash-free version and masters even heavy machining tasks effortlessly thanks to hydraulic clamping.

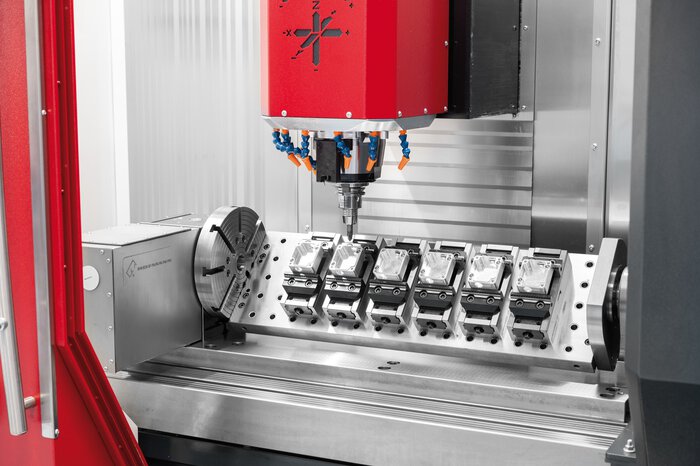

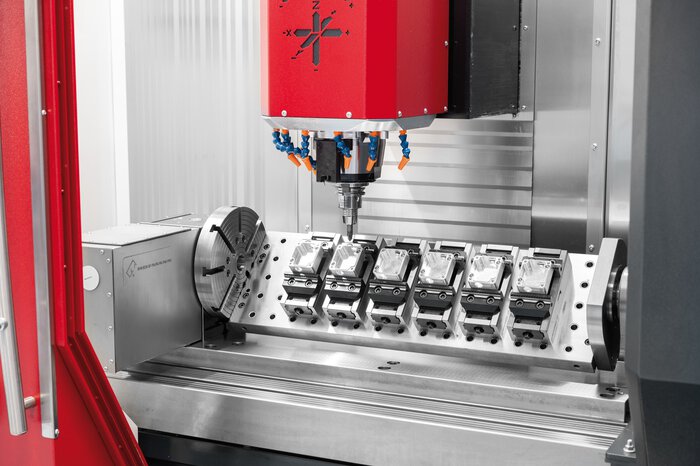

Standardised automation interfaces

Whether pallet automation or robot handling - the HEDELIUS machining centres in the ACURA series offer pre-configured interfaces for common automation solutions from EROWA, Indumatik, BMO or Cellro - for easy connection and commissioning.

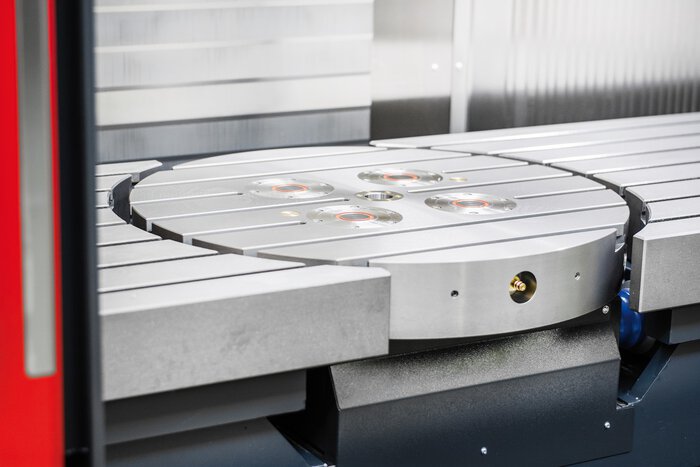

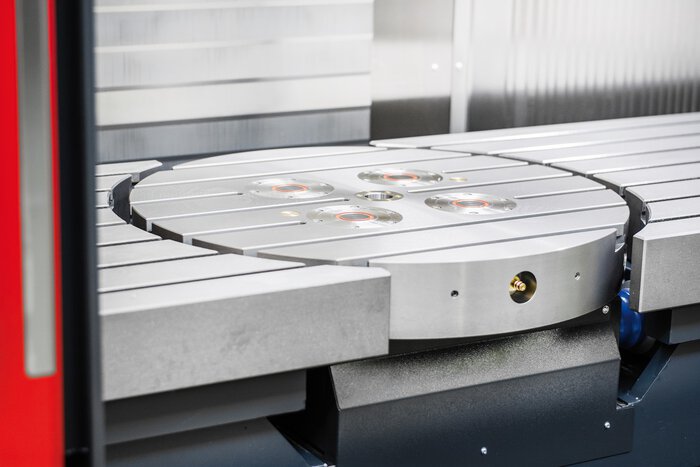

Clamping of the rotating/swivelling table on both sides

To ensure maximum stability even with heavy workpieces and during roughing, the rotary swivelling table in the ACURA series is clamped hydraulically on both sides. For 5-axis simultaneous machining (optional), the clamping can be deactivated via the M function.

Perfectly harmonised automation solutions

The MARATHON pallet magazine systems are completely designed and manufactured by HEDELIUS and are perfectly open to the machining centres of the ACURA series. High transfer weights, many pallets, low space requirements and the new Heidenhain pallet changer control guarantee universal yet rationalised production.

Heidenhain linear measurement devices

All HEDELIUS machining centres are equipped at the factory with direct Heidenhain linear measurement devices. This ensures high positioning and repeat precision in the long term.

For maximised chip runtime.

Optimising tooling times is crucial to closing efficiency and competitiveness in chipping. By using standardised processes and set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can reduce unit costs, save resources and increase flexibility. This not only enables improved machine and system utilisation, but also the efficient production of small batch sizes with consistently high quality. HEDELIUS supports manufacturing companies with a wide range of solutions and innovative technology to help them close these gaps.

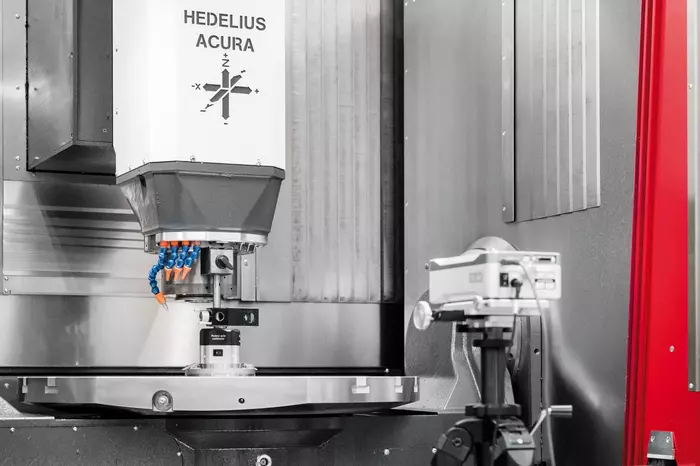

Measuring systems

We offer various optional features for tooling optimisation with regard to the measurement of your cutting tools. Using a tool probe or laser, which is attached to the machine table, you can automatically measure the length and diameter of the tools or check for tool breakage in the NC programme.

work area partition

By using a work area partition in the machining centre, two closed, independent work areas for economical chipping in oscillation mode can be created from one work area of the machine. The partition can be inserted or removed in just a few minutes.

Tool magazines

Providing the right tools plays an important role in optimising tooling times. With the help of our tool magazines, we offer you the option of drastically increasing the number of your tool positions or keeping particularly large tools directly on hand.

Zero point clamping technology

HEDELIUS machining centres can be equipped with zero-point clamping systems from GARANT ZeroClamp or SCHUNK NSE. With the help of this standardised interface, you can achieve a significant reduction in non-productive times by simplifying time-consuming cleaning, measuring, alignment and clamping.

Integrated NC rotary table

With an NC rotary table installed flush with the machine table, you can extend the range of applications of your TILTENTA from 5-sided to simultaneous 5-axis machining.

Mounted NC rotary table with counterholder

With NC-controlled top rotary tables, you can extend the range of applications of your HEDELIUS to include shaft machining or multi-sided machining, e.g. with swivelling bridges.

Swivelling bridge on base plate

NC rotary table-driven swivel bridges enable multi-sided machining with multiple clamping, thus rationalising series production.

Your requirements, your solution: discover all the optional features.

Optimise your HEDELIUS machining centre with a wide range of optional features that are precisely tailored to your specific requirements and production tasks. By making the right choice, you can avoid unnecessary downtimes, reduce production costs and increase efficiency. Standardised and optimised processes help to make better use of resources such as time and energy and permanently improve the quality of your products.

State-of-the-art control technology

What is usually considered special accessories is standard at HEDELIUS: All machining centres are equipped with a CNC full keyboard, colour monitor, spindle feed overdrive and original software as standard. State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality. You decide which system you want to work with.

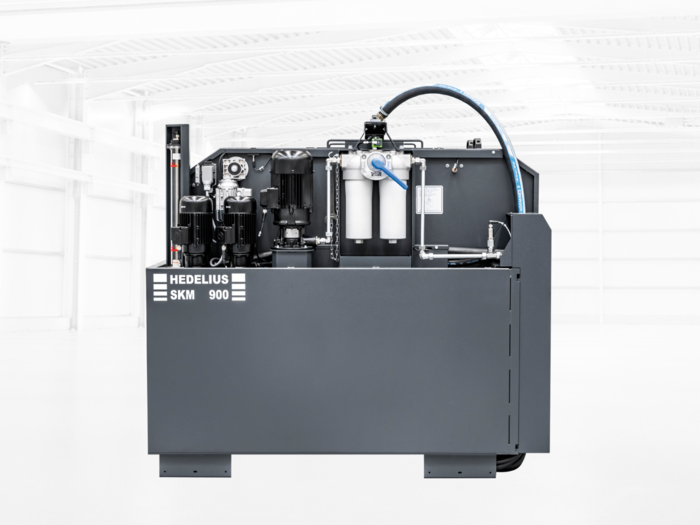

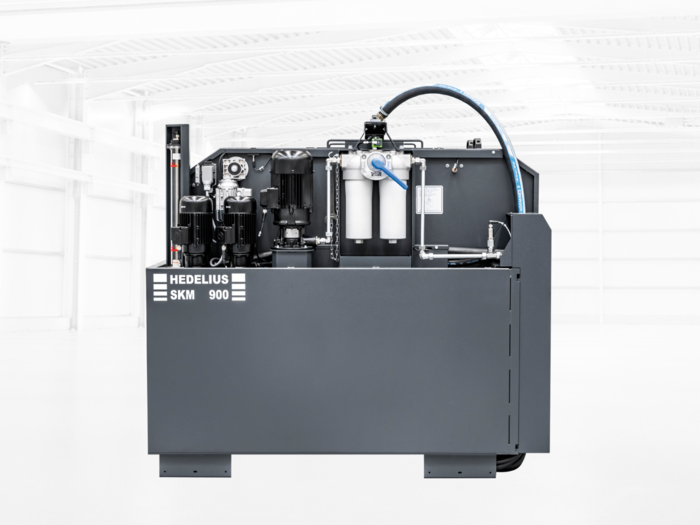

Cooling and lubrication

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre. In this process, the coolant is fed through the work spindle directly to the cutting edges of the tool. With the help of a wide range of additional equipment options, a Coolant system can be customised to your individual machining task.

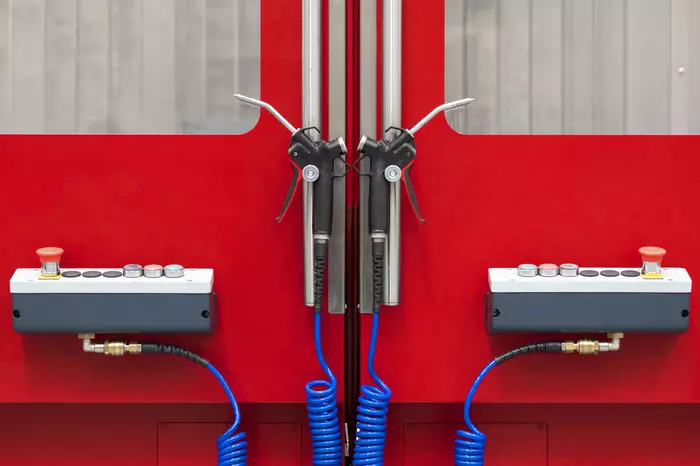

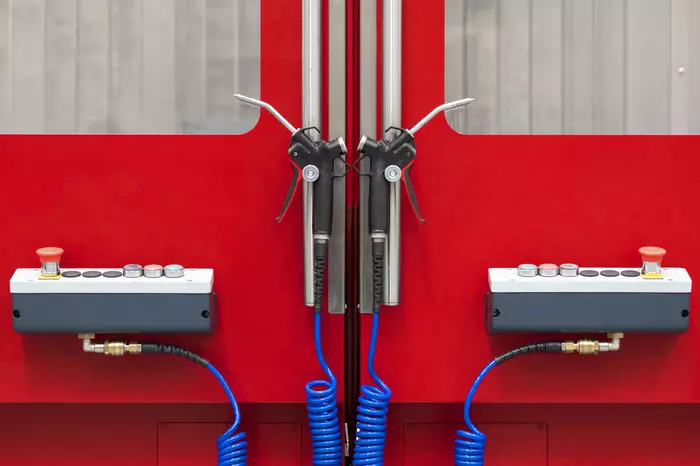

Additional cleaning technology

In addition to manually activated blow-off and rinsing pistols for removing chips and blowing workpieces dry, the CNC machining centres can also be equipped with additional rinsing nozzles, which increases process reliability, particularly in automated production and aluminium production.

Liquid-cooled motor spindles

HEDELIUS uses liquid-cooled direct drive spindles, so-called motor spindles, in its machining centres. You have the choice between different spindle designs from 8,000 to 24,000 rpm with outputs of up to 50 KW, as well as between SK or HSK variants.

Automatic doors

Motor-activated workspace doors on your CNC milling machine increase ease of use for your employees. Automatic doors are particularly recommended for short workpiece runtimes to reduce the workload on your employees.

Customised paint finish

Whether classic red, elegant white, bright blue or neutral anthracite - determine the appearance of your new machine to match your company and make a statement to your employees and customers as a modern manufacturing company.

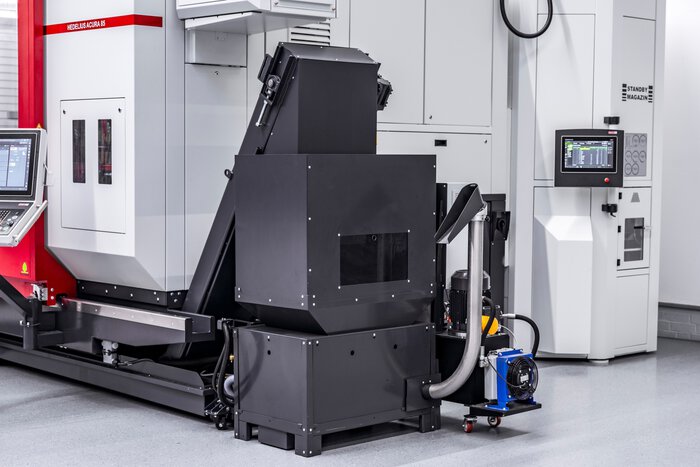

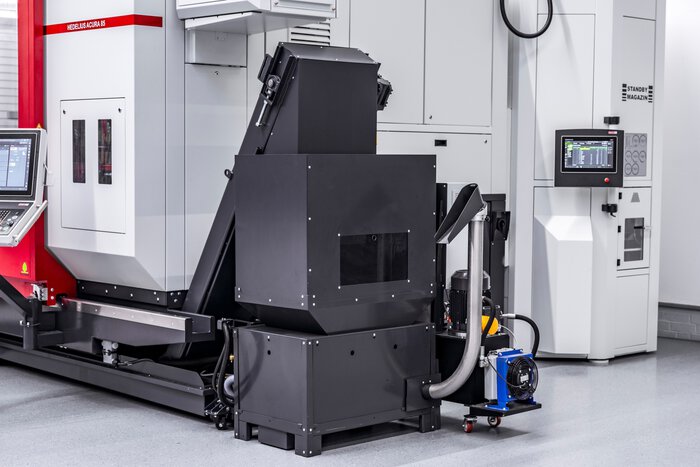

chip press

A chip press, which is connected to your CNC machining centre, separates the chips from the cooling lubricants and compresses them into clean, manageable briquettes. This reduces logistics costs, saves valuable resources, generates additional revenue and protects the environment.