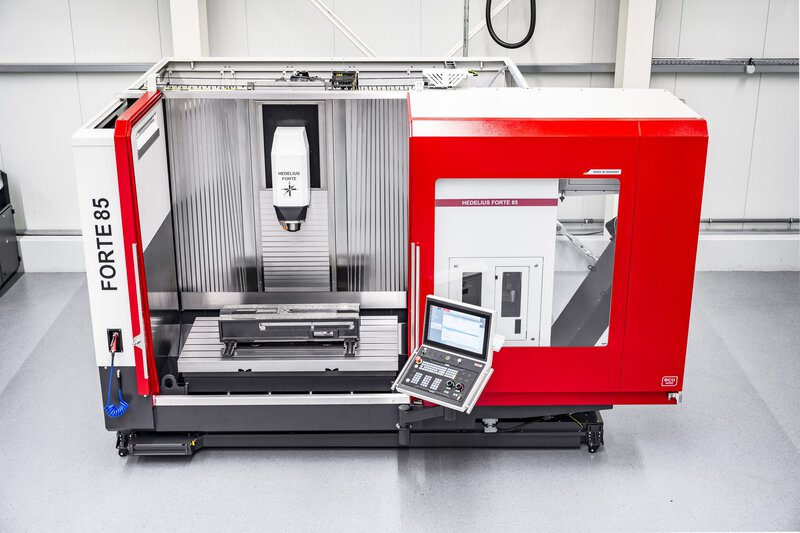

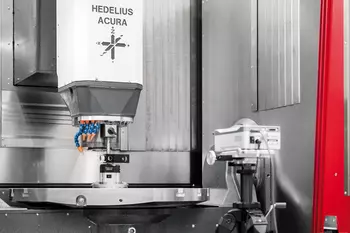

3-axis machining centre FORTE 85 Single 1620

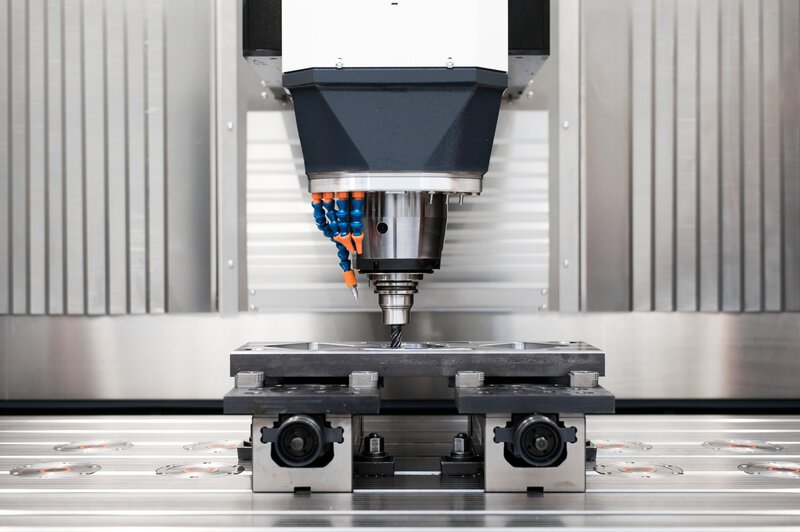

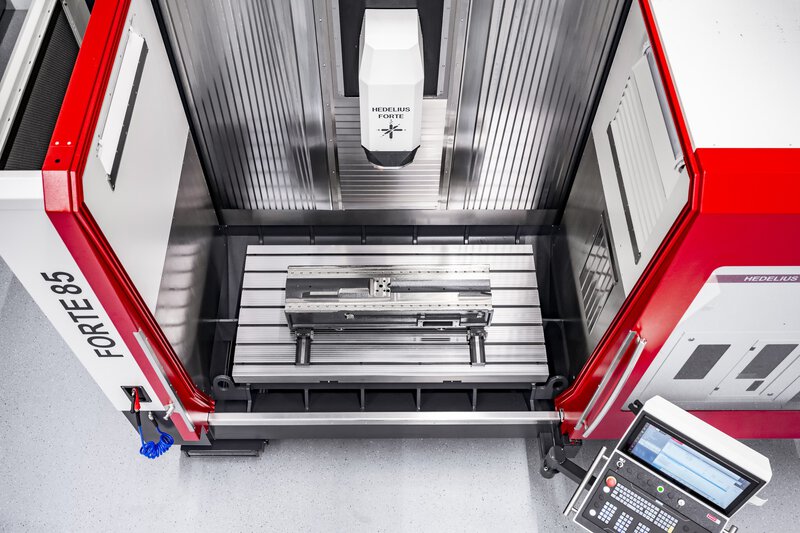

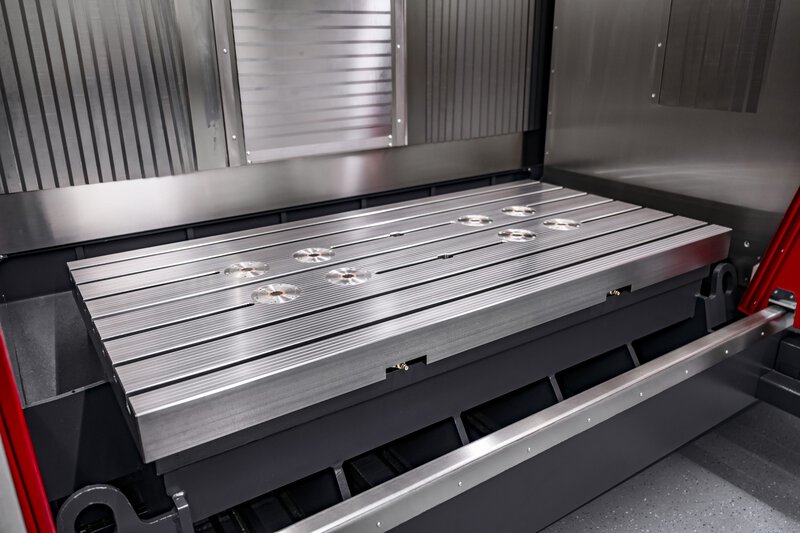

The large machine window and the fixed machine table ensure that everything is open to the operator so that the work area can be optimally utilised. Direct access to the workpiece is further supported by the ergonomic working height of the machine table. Vertical stainless steel covers ensure optimised chip fall - even when machining aluminium in bulk. This means that little time is spent on cleaning when working with the precise 3-axis milling machine.

Your advantages with the FORTE 85

- Generous X travel path of 1620 mm

- Extra-large Y travel path of 850 mm

- Direct measuring systems as standard

- Fully enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Travelling column made from high-quality machine casting

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

FORTE 85

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 1620 x 850 x 700 mm | - | - | |||

| Oscillation mode | ||||||

| Oscillation mode | - | - | - | |||

| Output | ||||||

| Output | 22 / 37 / 50 / 35 / 30 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 15000 / 18000 / 22000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 80 / 150 / 195 / 260 / 344 | - | - | |||

| Contact surface | ||||||

| Contact surface | 1800 x 900 mm | - | - | |||

| Fixed machine table max. load | ||||||

| Fixed machine table max. load | 1500/2000 kg | - | - | |||

Gallery of the FORTE 85 Single 1620.

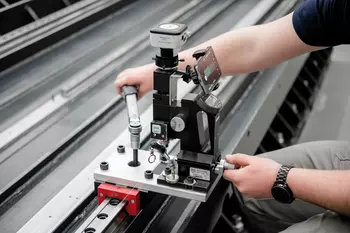

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.