BMO AUTOMATION.

For 3- and 5-axis machining centres.

Ideal for high variance and high volumes (High Mix | High Volume).

HEDELIUS automation partner BMO from Neederwert, the Netherlands, specialises in the development and production of so-called hybrid automation solutions. Hybrid means that a robot can load both pallets and workpieces by automatically changing grippers. Robots with a transfer weight of up to 250 kg are used to process a wide range of parts. Single parts, workpieces that are difficult to clamp or workpieces with increased accuracy requirements are produced on pallets during the day, for example, while larger series are produced unmanned at night or at the weekend. Alternatively, machining centres can also be linked to a pallet magazine for series with complex geometries or long runtimes.

Reasons for automation with BMO Automation.

Workpiece automation with BMO.

BMO supplies robot cells for loading and unloading CNC machining centres. This allows you to realise potential easily, quickly and cost-effectively - with safety in your production. With automation solutions from BMO, you become less dependent on the tight skilled labour market. BMO systems are suitable for either pallet or product loading, or a combination of both if required. The loading systems supply up to two CNC machines and are therefore even more economical.

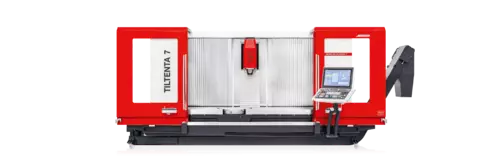

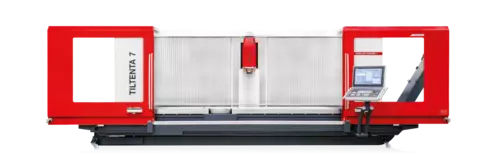

Machining centres with BMO interfaces.

HEDELIUS machining centres from the EL series have a pneumatic loading opening as standard. This standard interface enables you to automate your production regardless of the manufacturer. Your CNC machining centre from HEDELIUS can therefore ideally be supplemented with workpiece automation from the manufacturer BMO to enable unmanned production.

Reference reports from HEDELIUS customers.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

Your enquiry about BMO Automation.

Are you interested in a new HEDELIUS machining centre with a BMO Automation? We will be happy to make you an offer for a HEDELIUS CNC machining centre with a suitable automation system from BMO Automation.

We will be happy to help you and find the right product for you! Of course, you can also contact us by telephone at +49 (0) 5931 9819-0 or send an e-mail to sales@hedelius.de send.

This form requires your consent to third-party cookies. Privacy settings

Further information