The series at a glance.

HEDELIUS offers high-performance CNC machining centres for a wide range of applications. The ACURA series with rotating/swivelling table impresses with maximum precision in the smallest of spaces, ideal for demanding 5-axis machining in small series production. With the TILTENTA series, you can flexibly master large and complex machining tasks, for example in mechanical engineering, thanks to the swivelling main spindle. The range is complemented by the FORTE series, which covers a wide range of applications from compact 3-axis machining centres to long-bed machines for large parts.

series

ACURA

5-axis machining centres

with rotating/swivelling table

Super-compact & highly efficient

Small installation depth, low overall height.

Extra-long Z travel paths

up to 700 mm.

High clamping weights

up to 1000 kg.

Perfectly automatable

For maximum output.

series

TILTENTA

4/5-axis machining centres

with swivelling spindle

Universal machines

for high machining output.

Large collision area diameters

up to 1450 mm.

High workpiece weights

up to 6000 kg (fixed machine table) or 2200 kg (rotary table).

Long tools

and large tool diameters.

series

FORTE

3-axis machining centres

with fixed machine table

Vertical compact machines

FORTE 65/85, with large magazine.

Vertical long-bed machines

FORTE 7/9/10/11, up to 6200 mm X travel path.

Fixed machine table

For high weights up to 6000 kg.

Find the right

Machining centre

3-axis or 5-axis machining? Complex single parts

produce in series or heavy long parts economically?

HEDELIUS machining centres in use

Over 3000 well-known customers from all over Europe trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

The finest optics in a clean room and modern milling technology under one roof: at VITRONIC in Wiesbaden, high-tech meets craftsmanship. The company develops intelligent image processing systems that are used worldwide in logistics, industry and transport. VITRONIC relies on the TILTENTA 7-2600 NEO from HEDELIUS for maximum precision in production. The machine impresses with its flexible processing of individual and small series, well thought-out design, generous installation space and the possibility of expansion through pallet automation. Find out more about the successful collaboration between VITRONIC and HEDELIUS in the case study.

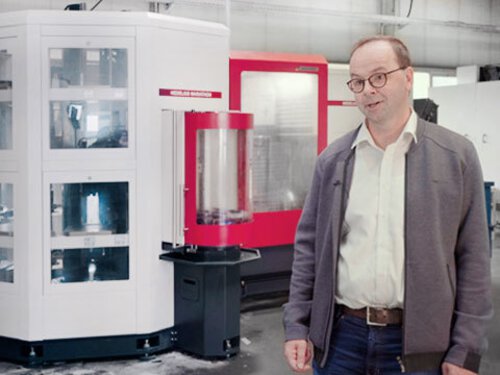

Highest precision, modern production technologies and a partnership-based cooperation with customers from demanding industries - Fraune Metallbearbeitung GmbH & Co. KG from Delbrück in East Westphalia is committed to this quality promise. In 2022, the family business led by Managing Director Heinrich Fraune took the first step into automated production - with the compact 5-axis machining centre ACURA 65 and the multi-pallet storage system MARATHON SR422 from HEDELIUS.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Over 3,000 CNC machining centres delivered in Europe -

Uncompromising quality from HEDELIUS

HEDELIUS is your reliable partner for high-precision CNC machining centres with 3-, 4- and 5-axis control. Our machines are used across all industries for milling and drilling metal and plastic workpieces. Users include tool and mould making, general and special machine construction, contract manufacturing, the food and packaging industries, agricultural machinery, medical technology and the air and space industries. Plastics processors also rely on the quality and precision of our CNC technology "Made by HEDELIUS".

Our machining centres are equipped with powerful CNC control systems from Heidenhain or Siemens and guarantee efficient and precise production. With around 250 employees, HEDELIUS is one of the leading German manufacturers of CNC machining centres, especially for demanding 5-axis machining.

The product portfolio includes 5-axis machining centres with different kinematics to optimally meet specific requirements. The ACURA series is equipped with a rotating/swivelling table unit (A/C kinematics) and offers maximum precision in a compact space. The TILTENTA series combines a swivelling main spindle with an NC rotary table (B/C kinematics) and enables maximum flexibility when machining large and complex workpieces.

Discover why HEDELIUS stands for precision, innovation and reliability - in every CNC machining process.