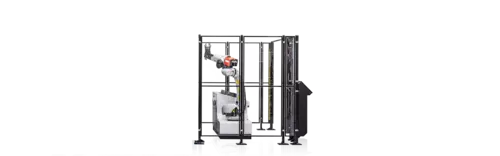

Workpiece automation.

Efficient automation for high volumes and serial production.

Workpiece automation offers you the opportunity to optimise your production and increase profitability. Whether for smaller batch sizes or in large-scale production - with a system based on industrial robots, you can significantly extend unmanned machine runtimes without the need for operating personnel. From handling simple workpieces to serial production: Workpiece automation ensures precision, efficiency and flexibility.

Systems for automated loading of workpieces.

The choice of the optimal automation solution should always be customised to your individual requirements. Depending on the number of pieces, workpiece dimensions and the desired unmanned running time, we offer you a wide range of solutions for automated loading of our CNC machining centres. In addition to our in-house automation solution for loading workpieces and pallets, the MARATHON RZ430, you have the option of choosing from a wide range of solutions from our renowned partners.

Secure advantages,thanks to automated workpiece loading.

Workpiece automation not only offers an efficient solution for processing large quantities, but also impresses with its flexibility and cost-effectiveness. From the optimisation of production times to the reduction of manual work steps - automation brings numerous advantages. Discover how you can improve your production processes and increase your competitiveness by using modern robot systems.

CNC users report from the field.

Machining centres for automation.

HEDELIUS machining centres from the EL series enable manufacturer-independent automation of production. Loading takes place via a pneumatically activated loading opening on the side of the machine. This means that the work area remains fully accessible for manual single part production as well as set-up and control work.