WKT-Wernemann Kunststofftechnik GmbH | TILTENTA 6-2300

Field of application: Plastics technology | Company headquarters: Geeste-Dalum, Germany | Employees: 100

WKT-Wernemann Kunststofftechnik GmbH is a second-generation family business that has continued to grow at its founding location in Geeste-Dalum. Since 1994, the company has been manufacturing GRP parts for a wide range of applications and in all shapes, from threaded rods to complete insulating housing. The non-conductive material is used for high-voltage systems, generators or switchgear, for example, but also in blast furnaces for the steel industry, for mechanical engineering and for power plant technology. Since 2015, WKT has also been producing GRP sheets itself on one of the world's largest press lines.

The base material GRP consists of various reinforcing fibres, usually glass fibres, and a resin matrix, which are pressed and bonded together. This produces sheet material in various thicknesses with different properties, which is further processed using machining processes, among other things. "Our customers are often surprised at how heavy the GRP components are," explains Thomas Wernemann, Managing Director of WKT. "And for machining, we need at least tools made of carbide or with diamond cutting edges. The glass fibres dull the tools very quickly." Further processing of the very stable material is therefore a major challenge.

Customised editing required.

WKT's 80 employees work with a wide range of machinery for the various products and applications. They use machines from woodworking to metalworking machines, which have to process the material as precisely as is usual in mechanical engineering. "Our parts are processed both wet and dry, and both have advantages and disadvantages for us," explains Production Manager Andreas Jestrabek. "For example, some customers specify that their parts must be machined dry. Wet machining requires subsequent cleaning, but the tool is protected and we can run higher feeds." Four HEDELIUS machining centres are available in the operation for wet machining.

Challenge glass dust.

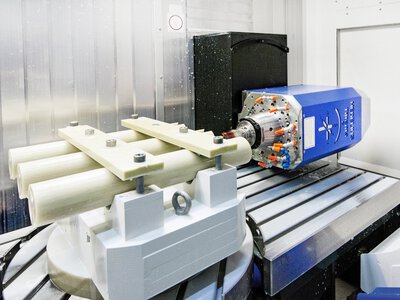

"The HEDELIUS machines are not as delicate as the portal milling machines that many of our employees have to deal with. They can handle more chips," reports Production Manager Jestrabek. However, the glass dust puts a strain on the bearings and guides, which therefore have to be lubricated continuously. However, during the maintenance of the first HEDELIUS machining centre, a RotaSwing 605, it was shown "that the bearings of the rotating/swivelling table are sealed well enough," emphasises Jestrabek. Bearings and guides thus remain virtually free of dust. For three-axis machining, WKT also has two machining centres from the C50 and C60 series as well as the TILTENTA 6 swivelling spindle machining centre. All machines are fully encapsulated due to the oil and resin vapours and dust and are operated with a specially manufactured exhaust system. The TILTENTA 6 is designed for high-precision simultaneous machining, as required for parts for superyachts, for example. In addition, HEDELIUS machining centres are generally used with various special devices for multiple clamping in the more economical oscillation mode.

Good solutions for manufacturing.

"We deliberately have a wide range of machines," says Managing Director Thomas Wernemann, "because each machine has its own strengths and refinements that allow us to get the most out of the machine." WKT has also developed its own machines and devices for many applications. For the powerful and precise volume machining of GRP, however, WKT opens up to HEDELIUS: "We said: We need something sensible for small parts. And then half an hour later we were in the car travelling to Meppen". In addition to the increased demand, the good service also led to the additional machining centres. "We are extremely satisfied with HEDELIUS," closes Thomas Wernemann, "you just have to pick up the telephone and you get an answer."

HEDELIUS machining centres of the customer.

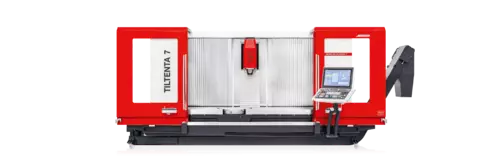

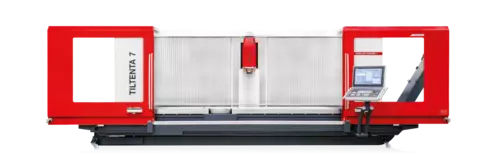

In accordance with market demand, HEDELIUS has designed the smallest size in the TILTENTA series to be significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.