HEDELIUS in machine and plant engineering

Discover a wide range of solutions

The machine and plant engineering industry is characterised by high precision, innovative strength, complex production processes and a wide range of applications. The industry is facing major challenges: global competition, a shortage of skilled workers, rapid technological development, sustainability and energy efficiency requirements and the digitalisation of production processes.

In order to remain competitive and drive innovation, investments in modern technology are essential. By investing in a HEDELIUS machining centre, thousands of operating companies in Europe have significantly increased their productivity and quality in recent years. More efficient, more flexible and more sustainable solutions secure the future viability and market position of our customers in the mechanical engineering sector and also make them more attractive for qualified specialists. Investments in leading tooling optimisation and automation technology are crucial for a long-term competitive advantage in the international environment.

Successful on the market with HEDELIUS machining centres

Companies in the machine and plant engineering sector are faced with the challenge of combining efficiency and precision in production. With CNC machining centres from HEDELIUS, our customers opt for technologies that meet precisely these requirements. Our machines not only offer outstanding quality and reliability, but also many years of durability in tough everyday production environments. Thanks to our innovative automation and set-up optimisation solutions, you can increase your competitiveness and secure a strong market position - now and in the future.

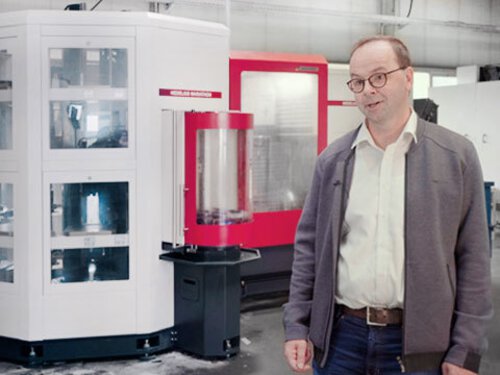

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.

The town of Georgsmarienhütte is named after the local steel company, which grew out of the local mining industry. Today, mining vehicles, special machinery and medical technology are manufactured in one of the former industrial halls of Georgsmarienhütte. Here and at another site, Wendt Maschinenbau GmbH und Co. KG manufactures a broad range of parts, machines, steel structures and devices on behalf of customers.

Machining centres for machine and plant construction

Machine and plant construction demands highest precision, flexibility and reliability. The CNC machining centres from HEDELIUS are specially designed to meet these requirements. Whether for machining large components or complex workpieces, our machines offer excellent chipping output and can be customised to suit different production requirements. With customised automation solutions and a large selection of machine models, we support you in optimising your production processes and increasing your productivity. Trust in the quality "Made in Germany" and secure decisive advantages in international competition.

ACURA

Precise and reliable 5-axis machining

The ACURA series was developed for 5-axis machining of complex workpieces with maximum precision and reliability. Thanks to the modern travelling column concept, it offers high accuracy and cutting performance. The compact dimensions allow easy integration into almost all manufacturing operations.

TILTENTA

Versatility and output

The high-performance machining centres in the TILTENTA series are ideal for versatile machining tasks in food and packaging technology. With a large work area and an infinitely variable swivelling main spindle, they enable vertical machining and precise 5-sided machining. The TILTENTA series has proven itself in challenging practical applications and ensures maximum precision and efficiency.

FORTE

Power and precision in heavy-duty machining

The FORTE series impresses with its impressive stability and performance, especially for demanding applications in machine and tool construction. With its robust design and powerful drive technology, it is optimised for heavy-duty machining. The FORTE models offer maximum precision and machining quality, even with difficult-to-cut materials.

Automation

Increased efficiency through automation solutions

Our customised automation solutions help to minimise staff shortages, reduce space requirements and increase productivity. HEDELIUS' optimally customised automation solutions enable medium-sized companies and large corporations alike to increase their efficiency and competitiveness.

Contact us

Find out more about our CNC machining centres and automation solutions and how we can optimise your production processes. Contact us for a personalised consultation and increase your efficiency and competitiveness with HEDELIUS.

This form requires your consent to third-party cookies. Privacy settings

Further information