FORTE series.

Discover the FORTE series - a new class of vertical 3-axis machining centres that offer maximum precision and performance in the smallest of spaces with state-of-the-art Operator's platform design.

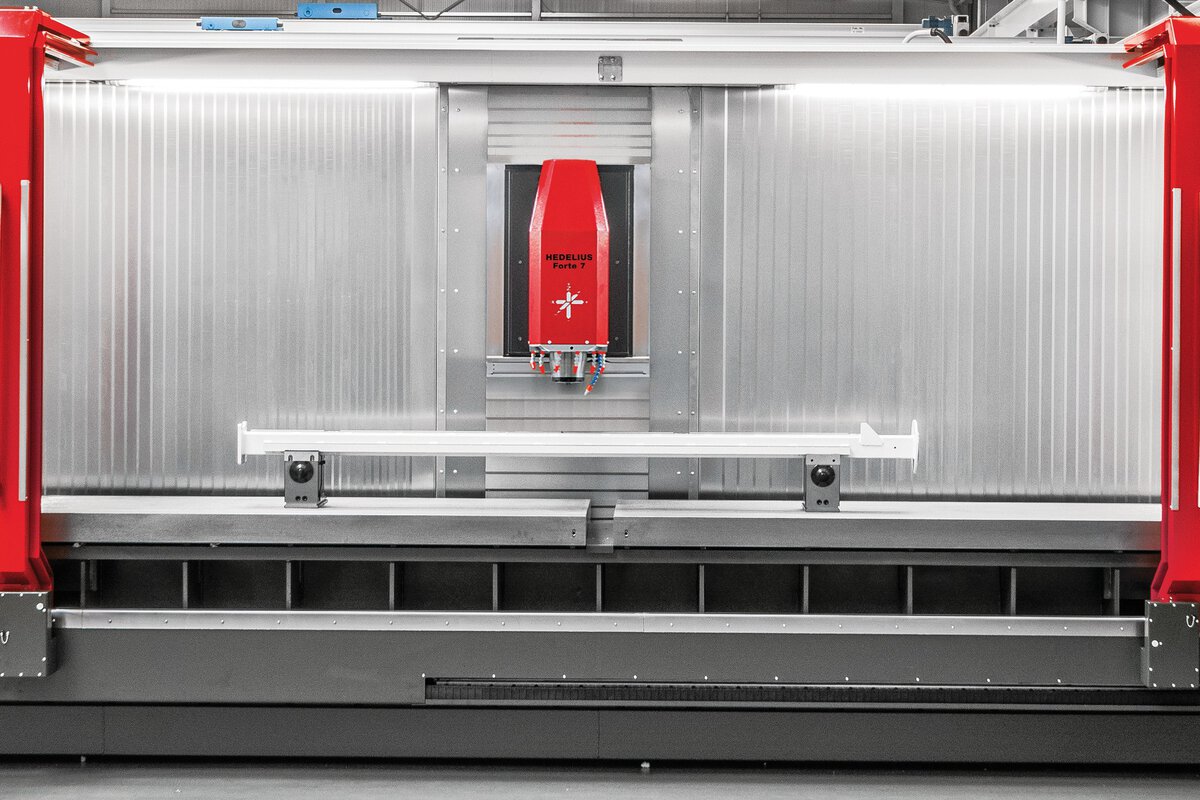

FORTE 7/9/10/11

Vertical long-bed machining centres.

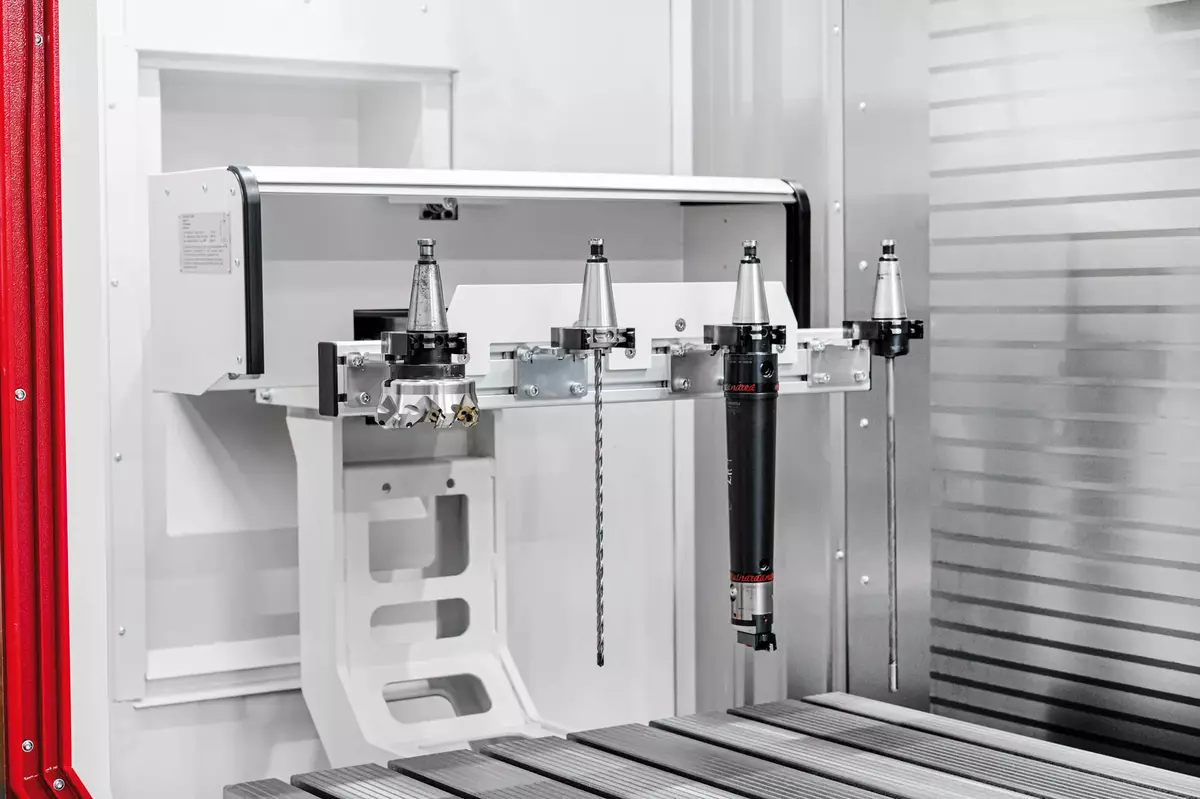

The FORTE 7/9/10/11 series are vertical travelling column machining centres with travel paths from 2000 mm to 6200 mm. The machining centres have a travelling tool magazine. This guarantees short tool change times at any point in the work area. The flexible travelling column concept allows the machining of long workpieces, series production in oscillation mode or the integration of rotary tables and swivel bridges. Thanks to the numerous variants and equipment options, this series can be customised to meet many requirements.

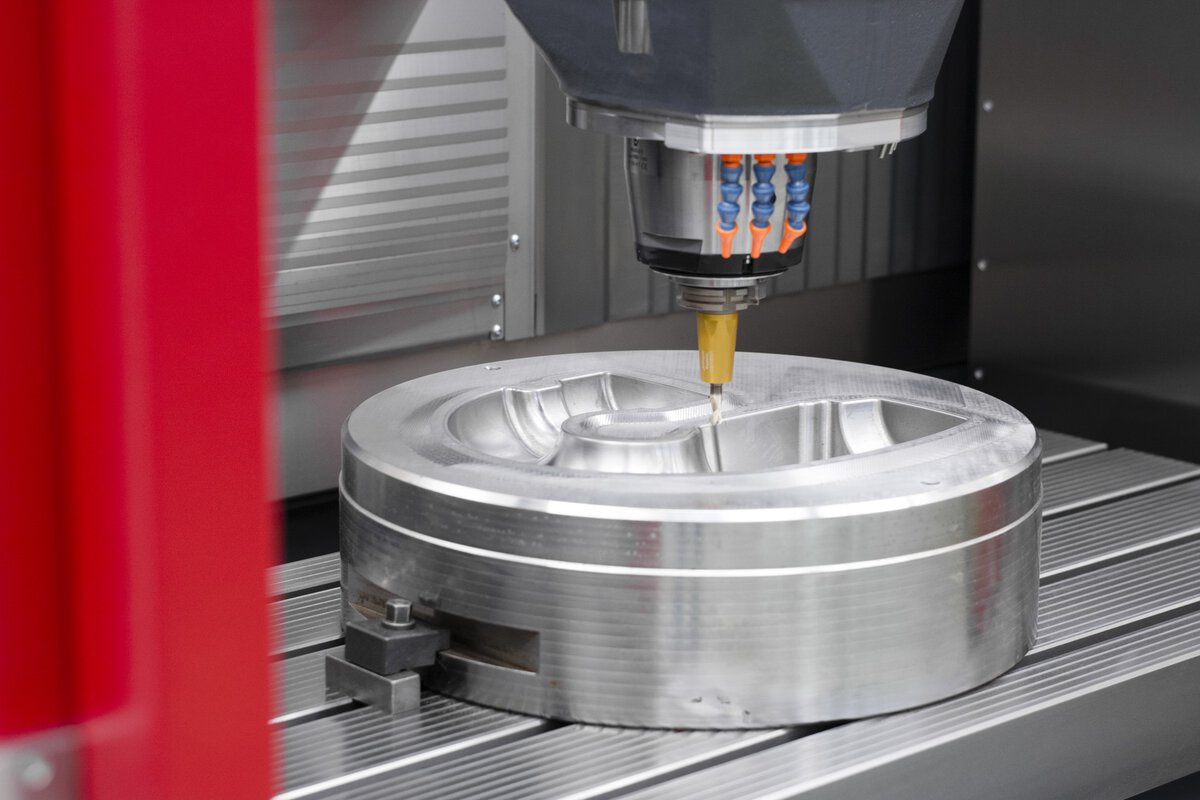

FORTE 50/65/85

Compact 3-axis machine with large tool magazine.

The FORTE 50/65/85 series are compact vertical machining centres with a fixed tool magazine and high dynamics. They offer maximum precision for workpieces weighing up to 2000 kg. The grey cast iron travelling column and the constant spindle distance to the Z axis guarantee excellent surface quality and Chipping output. Thanks to good accessibility and efficient chip removal, this series impresses demanding users in single parts and small series production in machine and tool construction as well as aluminium machining.

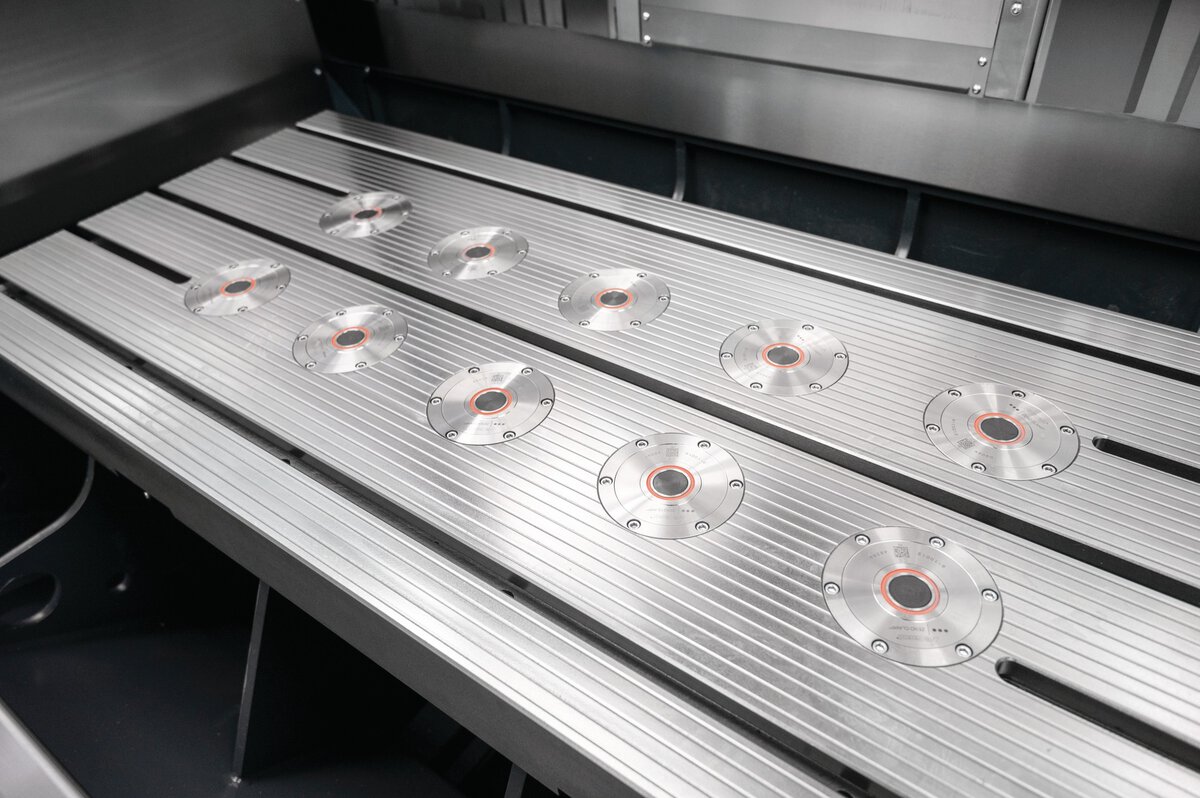

MAXIMISE PRODUCTIVITY

WITH AUTOMATED

long-bed milling machines

With automation solutions, our customers can

maximise the productivity of the systems - e.g.

through automatic operation in an additional shift

or at weekends.

FORTE series.

Vertical 3-axis machining centres with large fixed machine table.

Visit us at the

TECHNOLOGY CENTRE.

Experience the top performance of our CNC technology up close: We cordially invite you to visit our technology centre in Meppen and see the precision of our machining centres for yourself.

Reference reports from HEDELIUS customers.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

BL Lasertechnik GmbH turned a disaster into a success story. Despite the devastating fire that destroyed its production halls, the company opted for a quick restart. Thanks to the support of partners such as HEDELIUS, production was resumed and even expanded in a very short space of time.

"Never change a winning team" - this could be the headline for the collaboration between HEDELIUS Maschinenfabrik and automation specialist BMO at the Dutch manufacturing company Edumar Metaalbewerking. On the way to even more flexible unmanned production, the choice has now been made for the second time in favour of a joint solution from the two manufacturers.

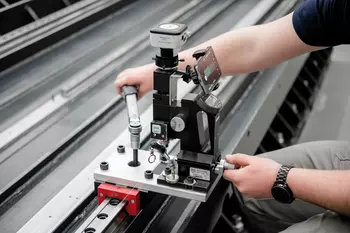

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.