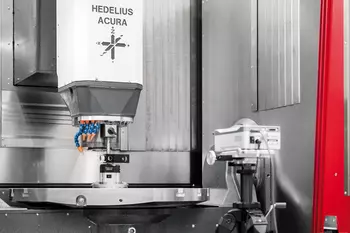

Vertical machining centre FORTE 9-6200

The FORTE 9-6200 not only impresses with its high dynamics, but also with an impressive travel path of 6,200 mm. This generous working range enables the machining of particularly large workpieces without compromising on precision. The sophisticated travelling column concept ensures that the machine maintains its stability and dynamics, regardless of the weight of the workpiece. The torsionally rigid travelling column made of grey cast iron also ensures excellent vibration damping, resulting in exceptional machining quality even with long travel paths and heavy tasks.

Your advantages with the FORTE 9-6200

- Large Z-axis travel path of 1005 mm

- Fully encapsulated work area

- Direct measuring systems

- Powerful, liquid-cooled motorised milling spindle with 14,000 rpm and 22 kW as standard

- Main spindles with SK40 or optional HSK A63 mount

- High table load due to fixed machine table

- 60-capacity travelling magazine

- Main time-parallel tool preselection by double gripper for short chip-to-chip time

- Vertical stainless steel slat cover for optimised chip fall

- Chip conveyor optionally in right-hand or left-hand design

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

FORTE 9-6200

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 6200 x 900 x 1005 mm | - | - | |||

| Oscillation mode | ||||||

| Oscillation mode | 2 x 2825 mm | - | - | |||

| Output | ||||||

| Output | 22 / 37 / 50 / 35 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 15000 / 18000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 60 / 130 / 175 / 240 / 324 | - | - | |||

| Contact surface | ||||||

| Contact surface | - | - | - | |||

| Fixed machine table max. load | ||||||

| Fixed machine table max. load | - | - | - | |||

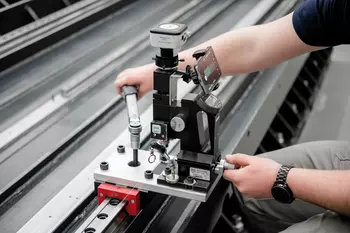

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.