Swivel bridges.

Expand your editing options.

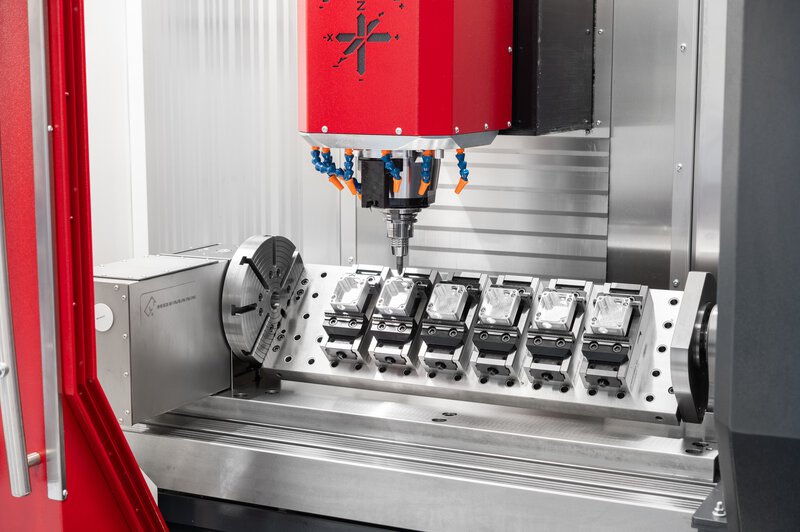

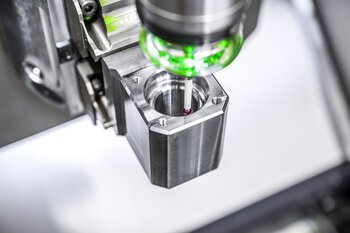

Swivel bridges driven by an NC rotary table enable multi-sided machining with multiple clamping and thus rationalise series production. Multiple clamping drastically reduces the non-productive times of the machine, as the chip-to-chip time, for example, is divided between the individual clamping nests. With quadruple clamping, the tool change time per workpiece is only a quarter of that with single clamping. At the same time, multiple clamping and multi-sided machining increase the machine's running time and the operator at the machine has more time to carry out ancillary tasks or operate a second machine.

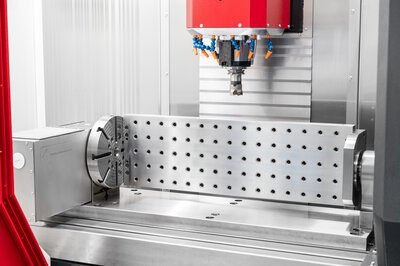

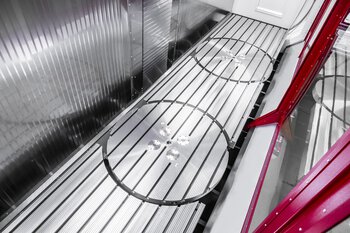

For quick retooling, the swivel bridges are mounted on a base plate so that they can be quickly installed and removed from the machining centre as required. The swivelling bridge itself can be equipped with grid holes or zero-point clamping systems to ensure that the clamps can be changed quickly. HEDELIUS offers both standardised swivel bridges and customised solutions. To further reduce the downtimes of the machining centre, the HEDELIUS long bed travelling column machining centres can also be used with two swivel bridges in oscillation mode. By inserting a work area partition, two machining areas are created in which clamping and unclamping can take place alternately.

While the swivelling bridge is loaded with new blanks in one work area, the workpieces are machined in the second work area. Changing the work area only takes a few seconds. We would be happy to advise you and present our solutions and options.