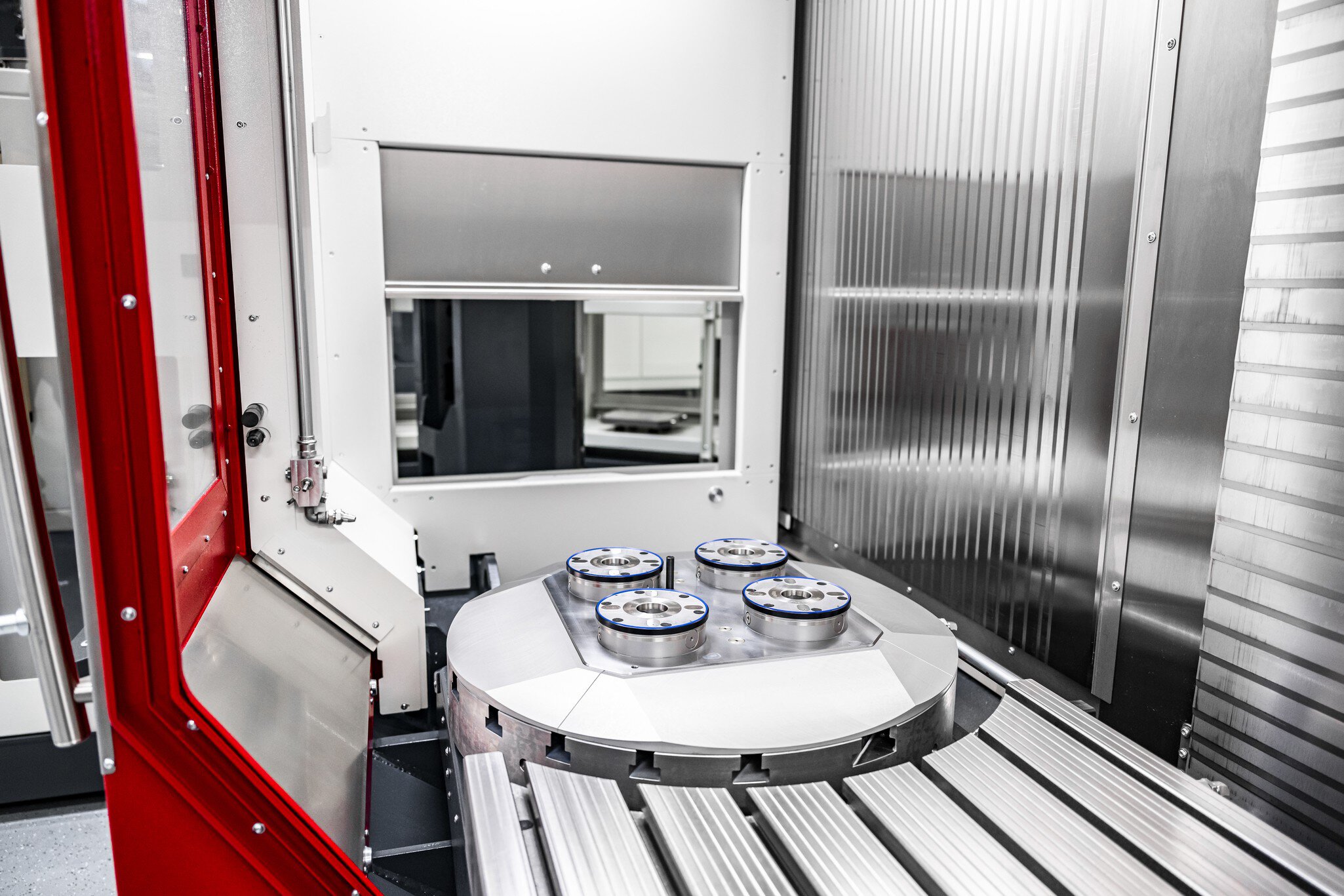

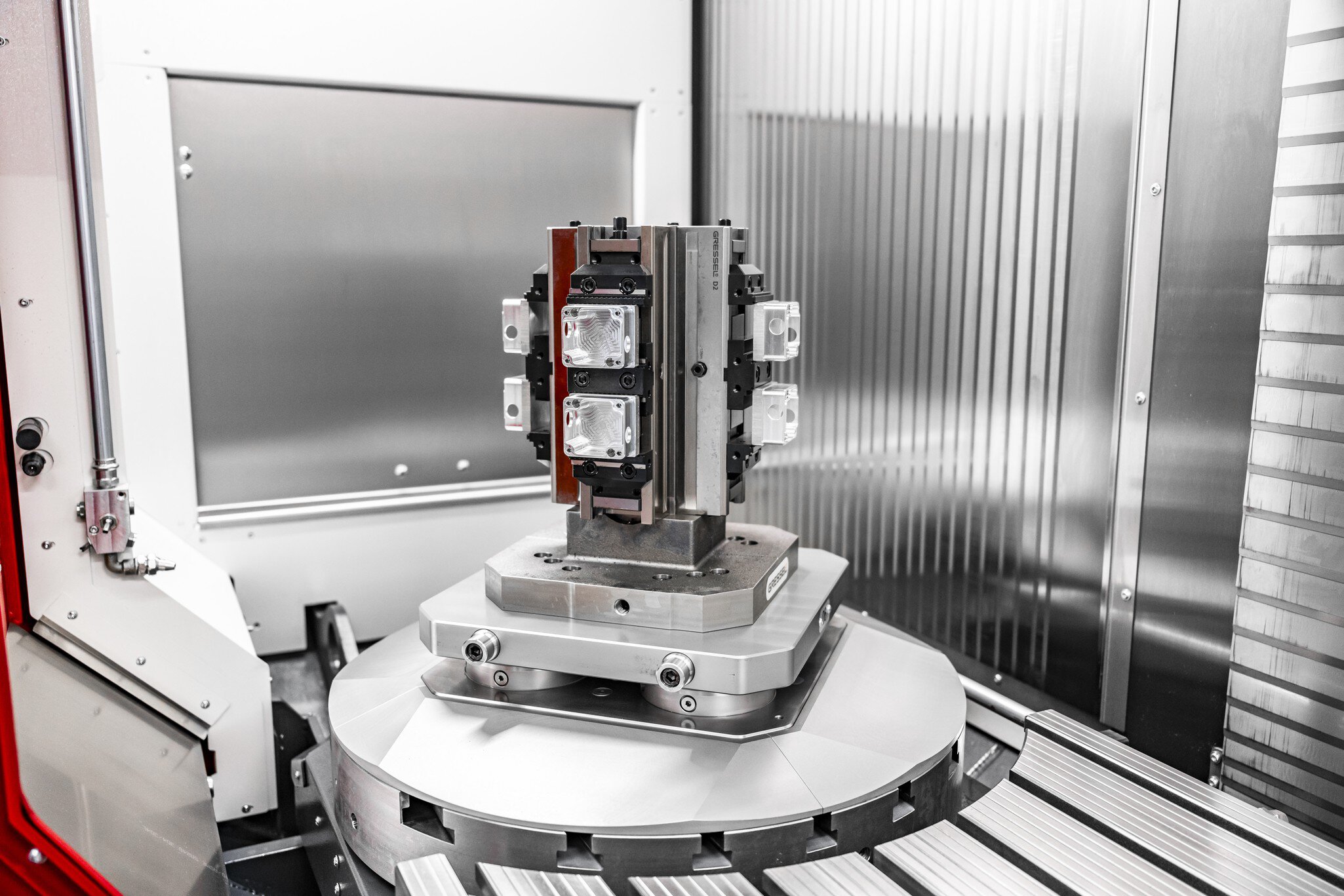

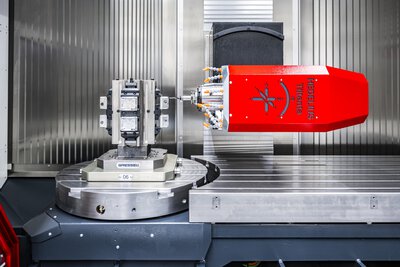

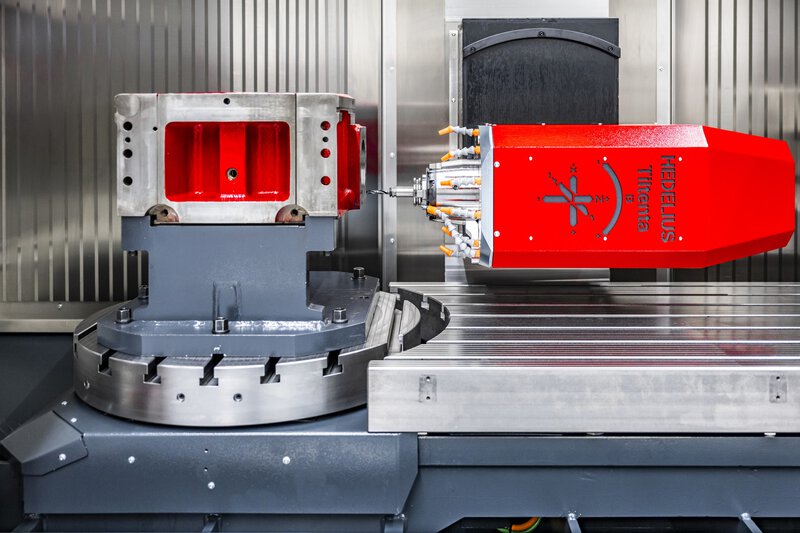

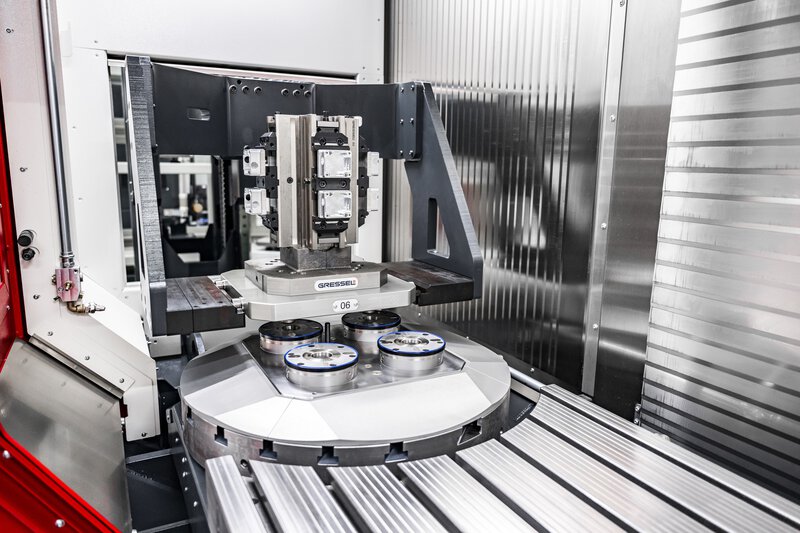

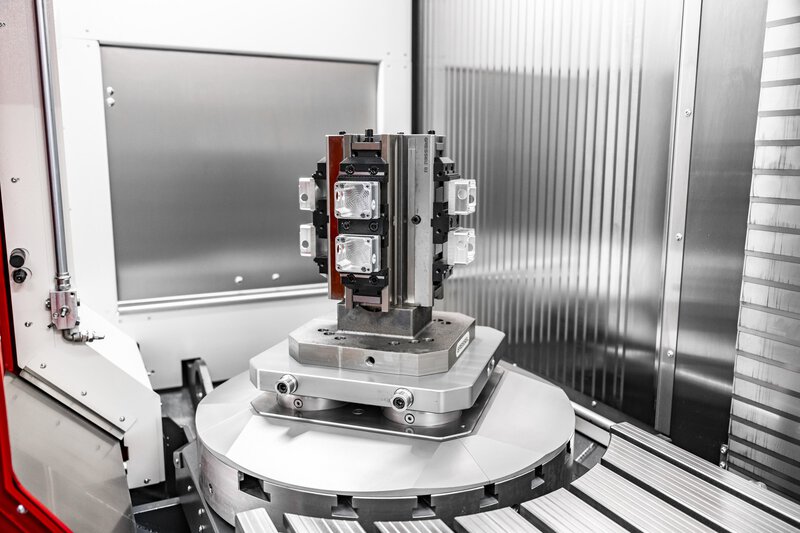

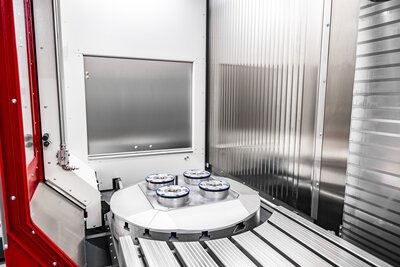

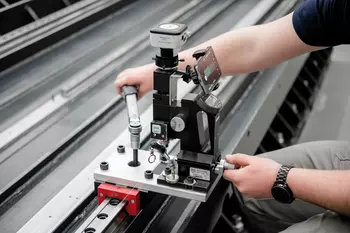

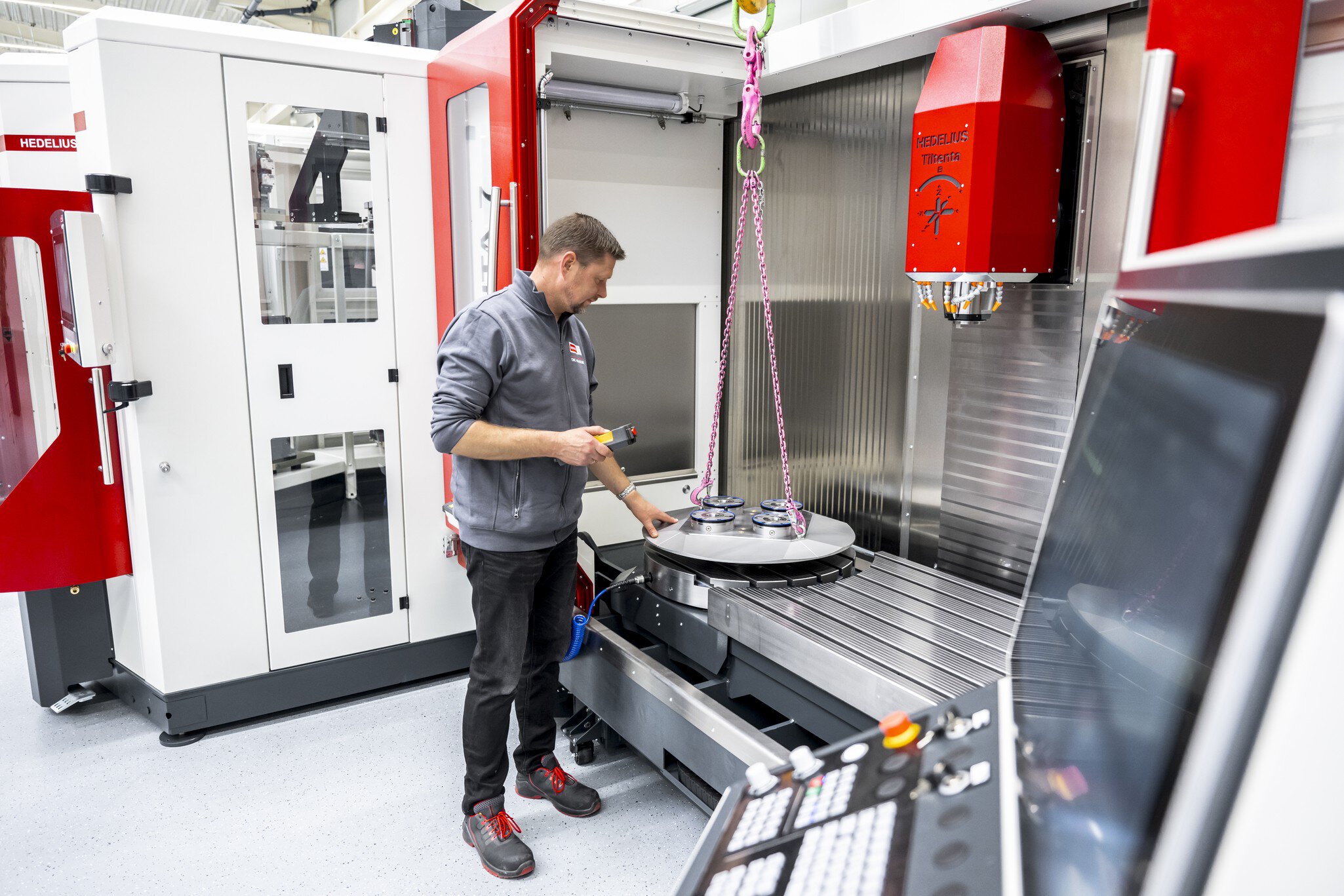

By using the automation table, the TILTENTA can be converted from single parts to series production in a matter of minutes. The user produces long, bulky workpieces during the day and small to medium series are produced unmanned in the evening or at the weekend.