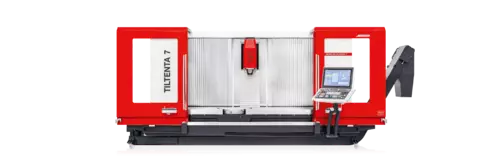

WERNERT-PUMPEN GmbH | TILTENTA 7-3200

Field of application: Process Technology | Headquarters: Mülheim an der Ruhr, Germany | Employees: 135

At WERNERT-PUMPEN GmbH, a specialist in pumping demanding liquids, the average batch size is between 1 and 100. In mechanical production, a TILTENTA 7-3200 from HEDELIUS with a large contact surface, mobile work area partition, standby magazine and zero-point clamping system creates the best conditions for flexible and productive machining of pump parts of different sizes, numbers and materials.

From the very beginning, WERNERT-PUMPEN has been a pioneer in the non-metallic pump industry. The world's first acid centrifugal pump made of plastic was developed here, as was the patented bellows seal. Today, the fourth-generation family-run company with 135 employees is one of the market leaders in its industry and is broadly installed. The product range extends from horizontal standardised chemical pumps and process pumps to vertical chemical pumps for wet and dry installation. "Our strength is our broad spectrum," explains Dr Klaus Etscheidt, who heads the company as Technical Managing Director together with the two managing partners Corinna and Ursula Hackenberg. "Almost every pump is unique". With this, the engineer has immediately addressed one of the company's challenges. Every customer has different requirements in terms of durability, delivery head and flow rate. WERNERT PUMPEN has a convincing answer to this: every customer gets exactly the pump they need.

Customers are mainly from the chemical industry. However, the pumps from Mülheim are also used for flue gas desulphurisation, in electroplating, for seawater desalination and in the food industry. "Our pumps convey media at temperatures from -150°C to +165°C. They can overcome delivery heads of up to 110 metres," explains Harald Piechnick, Head of Mechanical Production at WERNERT.

Flexibility is crucial.

WERNERT pumps are exposed to very extreme influences and have to pump aggressive, corrosive and solids-laden liquids. To meet these special requirements, the pumps are made of plastics such as polyethylene, polyvinylidene fluoride or polytetrafluoroethylene. The housing is mostly made of spheroidal graphite iron or mineral casting. Metal parts such as suspension tubes are also used. Flexibility is required in order to be able to manufacture customised pumps economically. For this reason, the decision was made in favour of a TILTENTA 7-3200 from HEDELIUS for mechanical production. "We have to be able to react flexibly to customer enquiries. Sometimes a pump or Spare part is needed at short notice, which we then have to manufacture individually," reports Production Manager Piechnick. The Tiltenta 7 from HEDELIUS guarantees this flexibility. The original plan was to purchase a smaller machine to replace an old boring machine. However, it was quickly realised that the TILTENTA 7-3200 offered significantly more options for releasing the wide range of machining tasks and increasing productivity. Thanks to the large X travel path of 3200 mm and the use of a work area partition, long parts as well as smaller components can be produced economically. "We do a lot of finishing work on pump parts made of mineral casting and plastic on the Tiltenta 7," explains Production Manager Piechnick. "But we also machine the ends of longer suspension pipes. Occasionally, moulds are milled from aluminium, which then run through two days." The challenges in production at the specialist from Mülheim are therefore many and varied. On average, the processing times are 20-30 minutes per component. Lead times are always an issue at WERNERT-PUMPEN, because shorter lead times also mean lower costs. For this reason, the company in Mülheim is keen to optimise tooling times.

Tooling times are minimised.

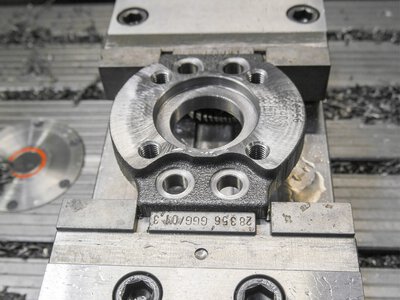

The HEDELIUS machining centre was equipped from the outset to minimise set-up times: with a work area partition, a standby tool magazine and a zero-point clamping system. "We manufacture some pump parts as a batch size one and may then have to produce them again a few years later. We then still have the end programs. All we have to do is clamp the components in the zero-point clamping system and we can get started," says Harald Piechnick, explaining one of the reasons for such a clamping system integrated on the table side. The batch sizes at WERNERT-PUMPEN are generally between one and one hundred. Frequent clamping and unclamping of workpieces is the rule. Hence the decision in favour of the work area partition and the standby magazine. These also help to reduce tooling times. By inserting the partition, a 3- and 5-axis work area is created on the TILTENTA 7-3200 for main time-parallel tooling of workpieces. The uncomplicated removal of the partition enables long parts to be machined in the shortest possible time. Up to 180 tools fit into the magazine of the standby magazine and are always immediately available for the various machining processes on the TILTENTA. "The magazine eliminates the need for tool presetting, which pays off," says Production Manager Piechnick, who is impressed by the magazine solution.

Made in Germany and service points.

In addition to these economic reasons, other factors were decisive in favour of the Tiltenta 7-3200 from HEDELIUS. Managing director Klaus Etscheidt explains: "We were looking for a supplier from Germany, preferably from the local area, in order to have the service nearby." This partner was found in the North German machine manufacturer HEDELIUS. They also opted for a German product in the form of Siemens for the control system and are very satisfied with it in Mülheim. "For us, this is the best control system for programming the machine," explains Harald Piechnick. Another decisive point in favour of a HEDELIUS machining centre was the compact design of the machine. The production hall dates back to the beginning of the 20th century, and the space is cramped due to supporting pillars and small gates. "We wouldn't have been able to fit an even larger machine in here," explains Production Manager Piechnick, adding with a smile: "We had to use a crane to bring the machine into the hall via the neighbours' garden anyway."

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.