WuM Werkzeug- und Maschinenbau GmbH | TILTENTA 7, ACURA 85 and FORTE 11-3600

Field of application: Automotive | Company headquarters: Mühlhausen, Germany | Employees: 30

When you visit WuM Werkzeug- und Maschinenbau GmbH in Mühlhausen, Thuringia, you get an impression of the end products that are manufactured using their tools from the entrance lobby: These are predominantly components for the automotive industry.

Founded in 1995, the tool manufacturer now employs a good 30 highly qualified employees and specialises in the development, design and production of high-precision stamping tools for the demanding automotive industry. Managing director Carsten Luhn explains: "We always have to be technologically up to date in order to remain competitive." In fact, customers are not only interested in precision and consistent quality, but also in speed and cost efficiency. Modern machinery is therefore essential for WuM.

3 x HEDELIUS: TILTENTA, ACURA, FORTE.

Three vertical high-performance machining centres from HEDELIUS Maschinenfabrik GmbH in Meppen have been standing next to each other in the production hall for some time now. "The TILTENTA 7 was purchased first and now we have the perfect addition," says Luhn happily. "With the ACURA 85, we have the nimble, fine 5-axis milling machine, which offers a surface quality that is close to polishing. In addition, we have the 3-axis FORTE 11, which also effortlessly processes large panels up to 3,500 mm in the X-direction and 1,100 mm in the Y-direction. Overall, we can react faster, have a larger throughput of components and can offer better prices."

Fast service via the HEDELIUS app.

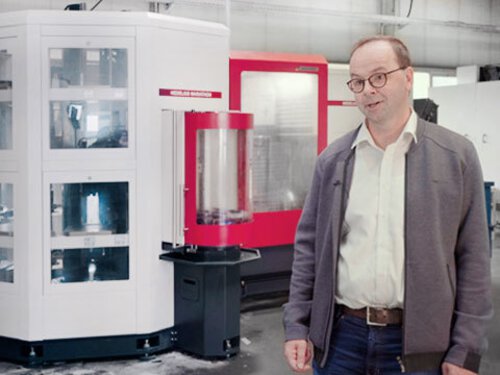

The factory hall looks very clean. Visitors immediately realise that work here is efficient and professional. And if there is ever a problem with a machine, an error message is sent to customer service via the HEDELIUS app. "We receive immediate feedback from Service and can usually rectify the fault quickly and easily in direct contact. This works extremely well," says Luhn. This enables the tool manufacturer to fulfil the high demands of its customers in the automotive industry.

Carsten Luhn makes a satisfied impression. Concentrated, but relaxed. He knows things are going well. Because in addition to his highly qualified and motivated employees, he has a machine park that he can rely on. According to Luhn, the Thuringians will certainly continue to work with HEDELIUS Maschinenfabrik in the future. "From experience - and because we always have to and want to be at the forefront of technology. We will certainly continue to find what we are looking for at HEDELIUS in the future."

HEDELIUS machining centres of the customer.

More testimonials.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.