Kreiselmeyer Umformtechnik GmbH & Co. KG | TILTENTA 7-2600

Field of application: Contract manufacturing | Company headquarters: Nuremberg, Germany | Employees: 60

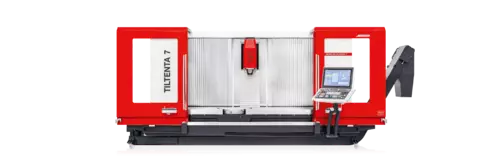

Found the right milling centre: The TILTENTA 7.

The factory halls of Kreiselmeyer Umformtechnik GmbH & Co KG in Nuremberg are dominated by systems for laser cutting, pressure, turning, edging and welding steel plates. However, with the increasing shift towards the production of complete assemblies, chipping is also becoming increasingly important. With the TILTENTA 7 from HEDELIUS Maschinenfabrik in Meppen, Kreiselmeyer has found the right milling centre.

Kreiselmeyer processes 100 to 120 tonnes of steel per month. In quantities of 1 to 1,000 tonnes, components and sophisticated assemblies are produced for a wide range of industries. Many of these are intended for medical technology, such as brackets for camera housings, housings for server motors or assemblies for control cabinet construction. In wind turbines, components for platforms and large ball bearing cages are made by Kreiselmeyer. Another field is mechanical engineering. For example, Kreiselmeyer produces all sheet metal parts and welded steel components for a manufacturer's injection moulding machines.

From metal spinning to system supplier.

When Hans Kreiselmeyer founded the company in 1960, the focus was on metal spinning, i.e. rotationally symmetrical forming from sheet metal. The company founder cut the sheets himself using sheet metal shears. "From a company specialising in forming technology, we have developed into a broad-based system supplier with a high level of vertical integration," says Thomas Kreiselmeyer, who is now the second generation of the family to run the company, which has a good 60 employees. With his sons Julian and Robin, both of whom also work in the company, the third generation is already in the starting blocks.

Flexibility and speed.

"The customer is interested in having as many links in their process chain as possible closed by one supplier," says Julian Kreiselmeyer, responsible for Sales & Marketing. "We can supply them with the parts in such a way that they can install the component or assembly directly as a kind of 'plug & play'. He knows that the quality is right." Flexibility and speed also play to the advantages of a family business.

However, the right technology is no less important. In view of the strategic focus on the production of complex, high-precision assemblies, the company decided to purchase a TILTENTA 7-2600 - a high-performance machining centre with a swivelling main spindle from HEDELIUS - in 2021. "The machine has everything we wanted," enthuses Thomas Kreiselmeyer, who works in programming. "This includes, for example, the very economical oscillation mode."

TILTENTA 7 - the best-selling HEDELIUS.

"The TILTENTA 7 is very popular on the market," reports HEDELIUS Sales Director Matthias Funk. "It is our best-selling machine." The spacious work area enables travel paths in the X, Y and Z directions of 2600/2030 x 750 x 695/800 mm. The fixed machine table has a high load capacity of 2,500 kg, while the rotary table with a diameter of 750 mm allows a clamping weight of an impressive 800 kg. Kreiselmeyer has selected a spindle with 29 kW output and a speed of up to 14,000 min-1.

The crossover concept of the TILTENTA 7 enables the mixed production of long, heavy workpieces and five-axis cubic workpieces in one machine thanks to the combination of a continuously swivelling main spindle with a long machine table with integrated NC rotary table. The long-bed machine can be equipped with a work area partition in a matter of minutes, e.g. to switch from front side processing of long workpieces to oscillating machining. This creates a 3-axis and a 5-axis work area for main time-parallel tooling.

Initially, Kreiselmeyer operated the TILTENTA without the partition in order to process large aluminium plates very precisely on the machine. In the meantime, the company is increasingly receiving orders for smaller series for which the oscillation mode is simply ideal in terms of cost-effectiveness. One example of this is V2A stainless steel camera mounts for computer tomographs, which have to be milled with high precision. Components for innovative X-ray machines are also a case for the TILTENTA 7.

"I would buy these again any time".

In addition to the right machine data, another factor was very important to Thomas Kreiselmeyer in the decision-making process: "People buy from people, and everything fitted very well between our companies. We wanted a manufacturer from Germany and were very happy that we found a convincing supplier in HEDELIUS, which is also a family business like us." Thomas Kreiselmeyer is also extremely satisfied with the stability, robustness and excellent workmanship of the machining centre. "I would buy it again at any time. You can tell that it's made in Germany."

Single-user assembly as a guarantee of quality.

Matthias Funk is delighted with the positive feedback and offers a glimpse behind the scenes: "We do indeed have a very high proportion of in-house production. All essential assemblies and machine elements, from the machine bed to the rotating/swivelling table, are machined in our 1,800 m² machining plant in Meppen." However, the employees in the assembly department also play a large part in the quality. Despite the continuously increasing order volume, HEDELIUS has decided against introducing shift operation. "Each machining centre is still assembled by a single team in the classic single-station assembly process. This team is responsible for 'its machine', which contributes significantly to the excellent quality of our products," Matthias Funk is convinced.

The customer has also already tested the machine manufacturer's service and also came to a positive conclusion. "You call and are attended to promptly, it's very quick," reports Thomas Kreiselmeyer. Forty service staff are on the road for HEDELIUS. Matthias Funk promises that if a fault is reported to the service centre by telephone, a technician will call back within half an hour.

Outlook Automation.

Robots have long since found their way into Kreiselmeyer's machinery. Gradually, chipping is also to be automated in order to reduce tooling times and to be able to work with process reliability over the weekend. A new turning/milling centre has already been ordered with the appropriate equipment. Kreiselmeyer would also have liked to buy such a machine from HEDELIUS, but the Meppen-based company is fully focussed on milling. "We do exactly what we're really good at," says Matthias Funk. "Including automation."

HEDELIUS machining centres of the customer.

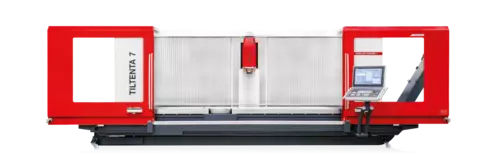

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.