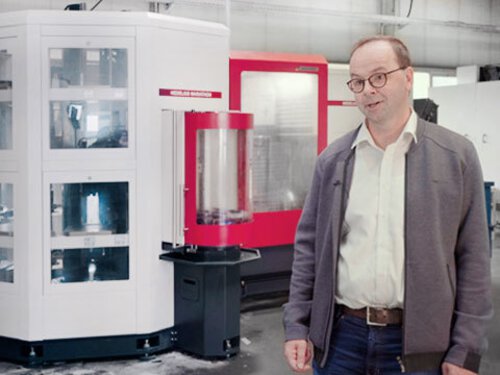

Piras Metalltechnik GmbH & Co. KG | TILTENTA 9-3600

Field of application: Metalworking, contract manufacturing | Company headquarters: Weissenstadt, Germany | Employees: 25

"Flexibility is the be-all and end-all."

A quarter of a century has passed since Guido Piras and his wife Monika founded Piras Metalltechnik GmbH & Co KG in the picturesque idyll of the Fichtelgebirge. Starting out as a small contract manufacturing business, the company from the tranquil community of Weißenstadt with its 3,000 inhabitants now employs 25 people and offers national and international customers from a wide range of industries innovative complete solutions in the fields of mechanical engineering, metal and electrical engineering, automation and special machine construction. With its modern and wide-ranging machinery, the operation covers a wide variety of production processes and batch sizes and manufactures almost 100% in-house. Guido Piras also swears by the loyal service of three CNC machining centres from HEDELIUS.

Return to the roots.

At first glance, the company building of Piras Metalltechnik GmbH & Co KG appears relatively inconspicuous: a production hall with an adjoining office wing and a few parking spaces outside the door. Once in the reception area, however, Guido Piras immediately points to a picture frame. Closed inside: Photos of a run-down building almost ready for demolition.

A mistake? Not at all: "So that we don't forget what we've already achieved together," he reveals proudly.

The building is the old premises of his former training company, to which he returned on 1 June 1995 and founded Piras Metalltechnik GmbH & Co KG. After years of vacancy, the building complex, which had been built at the beginning of the 20th century, was in a desolate state - but together with his employees, Piras took up the challenge and ventured into self-employment on this very site.

In the beginning, the operation was almost exclusively dedicated to contract manufacturing. "We were just four people back then," says the company founder, recalling the challenges of the early years. It was not uncommon to work through the night in order to be able to close orders on time. But their success proved them right, as their customer base and workforce grew.

As the company grew, special machine construction quickly became part of its range of services - a logical step for Guido Piras and at the same time a return to his own roots, as he had already worked as an employee in this range for twelve and a half years before becoming self-employed and had acquired extensive knowledge.

Highly modern CNC machinery.

The purchase of the first CNC machine in 1998 was a real milestone in the company's history. Piras had long been fascinated by the technology: "I was already a fan in the eighties," he remarks with a smile. Since then, the range of CNC machining centres in the halls of his operation has grown steadily. "We regularly invest in our machinery to ensure the high quality of our production in the long term and to meet the increasing demands of our customers," says Piras.

The necessary space for this was created in the course of two hall expansions in 2002 and 2013.

Two HEDELIUS machines in one year.

The second expansion finally paved the way for the purchase of the first two HEDELIUS machines: The compact RS 505K 5-axis machining centre was followed that same year by the RS 805 K23, a true all-rounder. "The investment that year was high, but both models have proven themselves since then and are still in use today," says Piras happily. The RS 805 K23 in particular had been on his wish list for some time due to its versatility: "It not only enabled us to machine long workpieces precisely, but also to produce series parts even more efficiently in oscillation mode," he says, explaining the increased challenges to the flexibility of his production.

Also included in both machines right from the start: a 180-position standby MAGAZIN, which automatically provides the required tools within seconds. "We were deeply impressed by the standby MAGAZIN, as hardly anyone offered anything like it at the time," emphasises Piras, opening up the enormous cost and time savings that can be achieved by eliminating the need for manual tool changes, especially with such a broad production spectrum.

Highlight of the TILTENTA 9-3600.

It therefore came as no surprise that the TILTENTA 9-3600, which was purchased in November 2019, was the third HEDELIUS machine to be equipped with a standby magazine. With its generous travel paths of 3600 x 900 x 900 mm (X/Y/Z), it is the largest machining centre in the machine park to date. Dominik Schöffel works on the new TILTENTA 9-3600 almost every day, and the machine operator finds the same high level of reliability that he is already familiar with from the other two models: "Everything works just as you would expect," he says happily. Equipped with a 6th horizontal axis, the TILTENTA 9-3600 is representative of the flexibility and precision that also characterises production at Piras.

The company's high in-house production rate of almost 100% makes it independent of suppliers and guarantees consistently high product quality, which Piras vouches for with conviction: "Everything that is manufactured here is under our control," he assures us. From the development of a customised solution concept through to its implementation, the operation handles all value creation steps itself. Individual and series parts are produced, sometimes in unusual shapes and in a wide variety of dimensions and batch sizes. Highly complex components, which can be manufactured on the TILTENTA 9-3600 to a reliably high quality, are always in demand, especially in special machine construction. The option of precise front side processing of long parts also pays off time and time again.

Own special chip.

Among other things, a new, in-house clamping device system for swivelling spindle machines with a flexible vice system is currently being manufactured and tested on the machine, which will also be compatible with components from leading clamping device manufacturers: "We are designing the special clamping device directly from practical experience. That's why we're confident that it will strike a chord with many other users," says machine operator Stefan Lautenbacher, commenting on the current status of the in-house development. Anyone who would like more information about a customised product can already contact his company, adds Piras.

"You can feel that people are actively thinking along with you."

Piras first became aware of HEDELIUS when he was an employee: "I still remember a RotaSwing display in MaschinenMarkt: I thought it looked very appealing," he reveals, "and that's still the case today." Above all, however, he now appreciates the technical advantages of the three machining centres: "Flexibility is the be-all and end-all for us, and HEDELIUS machines embody this one hundred percent," he says, praising the Emsland engineering spirit.

The picture is rounded off by what he describes as "excellent service": "We feel that we are well looked after here. Our machines are regularly serviced and we can always rely on quick help in the event of irregularities," he summarises. Piras also attests to HEDELIUS' exemplary customer orientation with regard to his most recent purchase: "You can tell that they really put a lot of thought into the design of the TILTENTA 9."

High confidence in the family business HEDELIUS.

This combination of German craftsmanship and reliable, personalised support is a real formula for success for Piras: "That's why we prefer to buy from family-run companies like HEDELIUS," he explains.

This is not the only reason why the Meppen-based company is one of a select group: "We try to limit ourselves to as few different manufacturers as possible in order to increase the flexibility of our employees and make it easier for them to switch between machines in their daily work," explains Piras, adding: "That's why we also prefer to use Siemens controls."

There are currently no concrete plans for further tumbler purchases, he reports, but the company will remain loyal to HEDELIUS in any case.

25 years of Piras Metalltechnik.

For now, however, the family business is celebrating its 25th anniversary - reason enough for Guido Piras to thank his entire staff for their commitment: "We are very lucky to have really first-class people in our ranks who are always willing to develop themselves further and whose commitment we have been able to rely on for years." He is also grateful to his wife Monika, who has been responsible for the administration of the operation as commercial manager since the company was founded, for her commitment and the "huge relief".

Although "self-employed" sometimes means "self-employed all the time" at Piras, life is still not closed. After work, the managing director turns into music lover Guido Piras. "I'm the typical 80s electro-popper," he reveals. As a guitarist, double bassist and singer, he has also been open on stage with his band for 38 years. So the next anniversary is already taken care of.

HEDELIUS machining centres of the customer.

More testimonials.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.