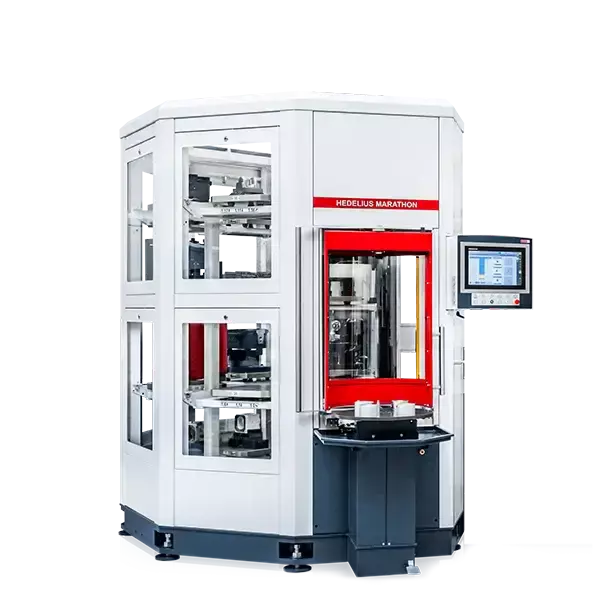

Multi-pallet magazine MARATHON SR422

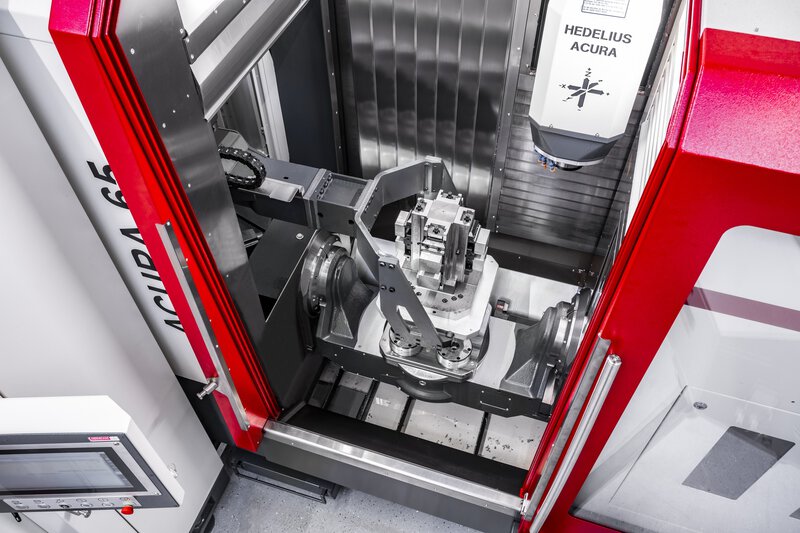

With 22 pallets of 400 x 400 mm each, the MARATHON SR422 multi-pallet magazine is perfect for the flexible automation of recurring single parts or small to medium-sized series. With its ergonomic loading height and a rotatable storage/retrieval station as standard, the system is optimally tailored to the needs of the operator. For optimised clamping, the pallet is locked in place at the loading station. The door of the storage/retrieval station can be fully opened for crane loading. The work area of the machining centre remains fully accessible from the front for process control and the loading of new workpieces. The automation system is perfectly open to the ACURA 65 5-axis machining centre.

Your advantages with the MARATHON SR422

- 22 pallets 400 x 400 mm

- Clamping weight 250 kg (270 kg transfer weight)

- Collision area diameter max. 500 mm

- Clamping height max. 400 mm.

- Storage/retrieval station as standard

- Pallet pneumatically locked on the storage/retrieval station for better clamping

- Query sensor for pallet on storage/retrieval station

- HEIDENHAIN control system for pallet changers

- Perfectly matched to ACURA 65

Get the best out of your production

HEDELIUS focusses on the user. This is why the MARATHON automations have been equipped with many technical details, such as the standard rotating set-up station or the pneumatic locking of the pallet on the set-up station for convenient clamping of workpieces.

Maschinenvergleich.

Fügen Sie weitere Maschinen hinzu um Leistungsparameter zu vergleichen.