Carstengerdes Modellbau & Zerspanung GmbH | ACURA 85 MARATHON with MARATHON SR518, TILTENTA 11-3600

Field of application: Contract manufacturing | Company headquarters: Bockhorn, Germany | Employees: 50

This video requires your consent to third-party cookies. Privacy settings

Further informationAutomation as a guarantee of success for satisfied employees.

When it comes to the working conditions in their own operation, managers often like to point to high employee satisfaction. But if you want to know exactly, it's best to ask the staff themselves.

At Carstengerdes Modellbau und Zerspanung GmbH from Bockhorn near Wilhelmshaven, everyone agrees: it's a great place to work. An appreciative, informal working environment and modern machinery contribute significantly to this.

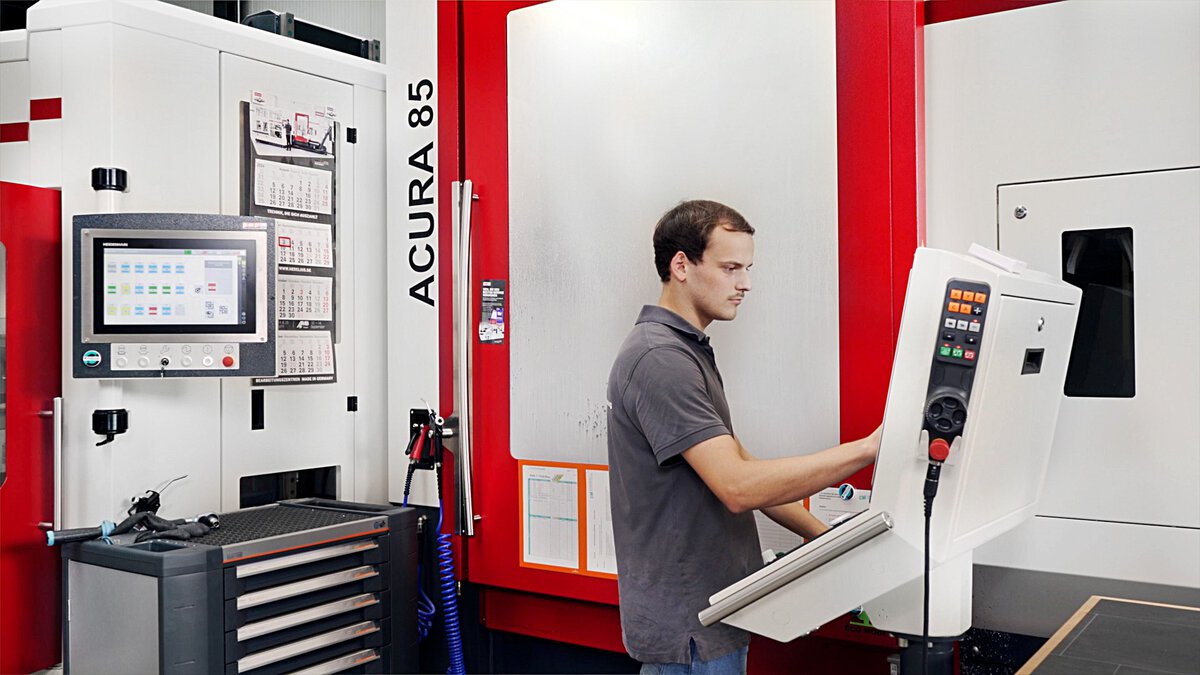

"Thanks to the acquisition of a modern 5-axis machining centre with automatic loading, we were able to convince a young employee who had considered starting university after his training to stay with us," says Managing Director Hendrik Carstengerdes happily. "The automation is a big step forward, technically open and powerful. Of course, it's fun to work with it."

The automated ACURA 85 MARATHON machining centre is used by the Carstengerdes contract manufacturing company to machine many different components for mechanical engineering, the aviation industry and other sectors.

Impressive key technical data

The technical data of the automated production system is impressive: the MARATHON SR518 pallet handling system has space for 18 pallets, each measuring 500 x 500 mm, with a clamping weight of 435 kg per pallet. With a spindle speed of 18,000 rpm, a spindle output of 35 kW and a torque of 136 Nm, the ACURA 85 5-axis machining centre with rotating/swivelling table is the perfect choice for demanding tasks. Both the machine and the automation come from HEDELIUS. The components are perfectly harmonised and ensure long spindle running times.

Carstengerdes explains: "We currently have 14 pallets tooling with different components. This gives me a running time of 30 hours."

State-of-the-art production on 3,500 m²

Like many success stories, Carstengerdes' began modestly: Hendrik Carstengerdes' father Herbert founded the company in 1987. From its beginnings in a garage, the operation has developed over the years into a state-of-the-art manufacturing company with 3,500 m² of production space in three halls. Carstengerdes employs around 50 people. The company manufactures for demanding sectors such as plastics processing, mechanical engineering, aviation technology and the defence industry.

For Kristian Engel, working on an automated system was a good reason to stay with Carstengerdes after his apprenticeship at the company.

Managing director Hendrik Carstengerdes is very satisfied with both the machines and the service from HEDELIUS.

The large pipe bending mould was one of the first workpieces milled on the TILTENTA 11.

"A large machine for large components".

In order to meet the increasing requirements, Carstengerdes consistently focuses on further development - both in terms of equipment and the qualifications of its skilled labour. The most recent example is the purchase of the HEDELIUS TILTENTA 11-3600. "We needed a large machine for the large components," explains Hendrik Carstengerdes. "We are very satisfied with the ACURA, with the service from HEDELIUS too, and the accessibility of the TILTENTA is optimal - all reasons why we decided in favour of HEDELIUS again."

With its infinitely variable swivelling main spindle, an extra-large Y travel path of 1,100 mm, an interference circle of 1,450 mm and an integrated NC rotary table for workpieces weighing up to 2,200 kg, the TILTENTA 11 is suitable for precise 5-axis chipping of large components as well as for vertical machining of long parts.

While the machine was still being delivered from Meppen to Bockhorn, the future operators received training at the HEDELIUS CNC Academy in Meppen. Machining mechanic Matthias Mietner emphasises: "For me, a machine has to be as uncomplicated as possible to close. It is also important that the tooling times are short and that the programme sequence remains stable. The TILTENTA fulfils these requirements perfectly. The training provided directly by the manufacturer was a great advantage."

Strong partnership for sustainable success

The TILTENTA 11 is now in use at Carstengerdes. Matthias Mietner draws a positive conclusion: "After the training, I feel confident in using the machine. And if we have any questions, we can contact customer service at any time."

The close cooperation between subcontractors and machine manufacturers shows what modern partnerships can look like. If everyone involved is convinced, a bond is created that goes far beyond the life cycle of a machine.

Cutting machine operators Matthias Mietner (left) and Tobias Schick (right) were optimally prepared for operating the TILTENTA 11-3600 at the HEDELIUS CNC Academy in Meppen, and were given the opportunity to learn how to use the TILTENTA 11-3600.

HEDELIUS machining centres & Automations of the customer.

More testimonials.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.

Heidkamp Metallbearbeitung in Hüllhorst** relies on maximum flexibility, quality and adherence to deadlines in the production of milled parts. The 5-axis machining centre ACURA 65 EL from HEDELIUS, combined with a large tool store, pallet pool and GRESSEL centric clamps, ensures short tooling times, automated individual and small series production and reliable processes, even with complex components and tight delivery deadlines.