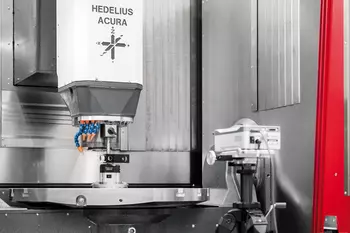

Vertical machining centre FORTE 7-2000 NEO

Where conventional CNC machining centres with a moving table reach their technical limits in terms of travel paths, dynamics, table load and chip removal, the FORTE 7 series offers a solution. The Operator's platform design impresses with its high table load, consistent dynamics (regardless of workpiece weight) and optimised chip fall. The closed full cabin and integrated exhaust system ensure a clean working environment. The sliding control panel and the large viewing windows make set-up and process control easier for the operator.

Your advantages with the FORTE 7-2000 NEO

- Large X travel path of 2000 mm

- Extra large Z travel path of 800 mm

- Fully enclosed work area

- Vertical stainless steel cover for optimised chip fall

- Travelling column made from high-quality machine casting

- Travelling tool magazine with 45 pockets for short chip-to-chip times

- Optionally up to 309 tools in the magazine reduce your tooling times

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

The basis of precision.

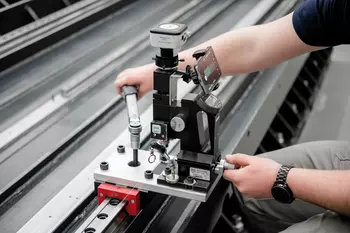

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.