Martin CNC-Präzisionsteile GmbH | TILTENTA 6-2300

Field of application: Contract manufacturing | Company headquarters: Asslar, Germany | Employees: 15

Martin CNC-Präzisionsteile, a contract manufacturing company based in Asslar, Hesse, has opened up its chipping operations to machines from HEDELIUS, thereby significantly expanding its product range. Another benefit: the high level of accuracy thanks to five-sided machining.

"Our range of parts is broad."

Martin CNC-Präzisionsteile specialises in the turning and milling of single parts and small series. Almost ten machines - a mixture of turning and milling centres with three and five axes - shape the parts. "Workpieces up to 2.3 metres in length are practically possible," explains Holger Martin, founder and managing director of Martin CNC-Präzisionsteile. Batch sizes at the contract manufacturing company range from 1 to 1,000 units. Aluminium, all types of steel and plastic are machined - "but aluminium accounts for 80 per cent of all workpieces," explains Holger Martin.

Most of the parts are intended for general mechanical engineering and are later used in packaging, pressure or grinding machines, vacuum systems, linear drives or in devices for the automotive industry. Martin emphasises: "Our range of parts is broad. We manufacture whatever the customer wants." The company has 15 employees and an area of 1,000 square metres at its disposal. For a few years now, customers have increasingly been asking for complete components. "That's why we also assemble them," says Martin. Only the surface treatment is carried out by external suppliers.

Convinced by HEDELIUS at the METAV.

The two newest machines in the machine park are two machining centres from HEDELIUS with travel paths of 2,300, 600 and 800 millimetres in the X-, Y-axis and Z-axis. The first 'TILTENTA 6-2300' was purchased four years ago. The reason for the purchase was a customer who had requested parts with a length of two metres for his special machines. However, the contract manufacturing company was unable to produce such long parts with the existing machining centres and had to turn down the order. "We then looked for a machine that was suitable," recalls Holger Martin.

No sooner said than done: In March 2014, the managing director and his team travelled to Metav in Düsseldorf and inspected the HEDELIUS machines at the stand. After the trade fair, the machining technicians travelled to the production site in Meppen in Emsland. They were able to see the machining centres under chip load in the demonstration centre. And the contract manufacturing company decided in favour of the T6 while still on site.

Little competition.

"We had already discussed possible suppliers beforehand. When a new purchase is pending, the employees who will be working on the machine afterwards are 100 per cent involved," Martin assures us. And there are not many manufacturers on this scale, the managing director continues. One of the most important reasons for the T6 was the long travel path of 2,300 millimetres in the X-axis. This means that the company can now process a wider range of parts and a number of orders have been added. "That has really helped us move forward," emphasises Holger Martin.

Thanks to the option of five-sided machining, accuracy has also improved: "Previously, with the three-axis machines, we had to do a lot of tinkering to achieve the required tolerances," explains the Managing Director. "Now we can completely manufacture the parts with accuracies of 0.01 millimetres in a single clamping operation. " The time required for set-up has also been reduced.

A reliable service.

Another criterion was that HEDELIUS is a German manufacturer. This was extremely important to Holger Martin because he had had bad experiences with milling machines from a foreign manufacturer in terms of service and spare parts deliveries. As a contract manufacturing company, Martin CNC-Präzisionsteile is always under pressure. If delivery times are delayed because the manufacturer has to wait for Spare parts, it can really hurt. Good service is therefore extremely important.

And the service at HEDELIUS is really top, praises Holger Martin. It all started with the commissioning. Back then, everything "worked perfectly", says the managing director. Everything went according to plan and after four days the T6 was up and running - including training for the five-axis programming and familiarisation with the machine.

If there are problems, HEDELIUS can react quickly. It is important for the family-run company with flat hierarchies to keep the time it takes for a service call as short as possible. Proof of the short response time: when a hose broke on the T6 in November, a service technician was on site with Spare parts on the same day. For cases like this, the machine manufacturer offers a service hotline and an app.

Customers can simply download the app - developed by HEDELIUS - enter their contact details and create their machines with machine numbers. If necessary, they can then report a service case, order Spare parts or book maintenance. In the event of a malfunction, the customer can also take photos or videos. This allows his team to prepare more quickly and decide whether the problem can be released by telephone or whether a service technician is required on site. Regardless of this, the machines are serviced once a year. This involves a technician checking the functions and replacing wearing parts.

"We will continue to work with HEDELIUS."

"We liked the T 6 so much that we ordered the same machine again last year," says Martin. It was delivered six months later, in May 2018, and training was no longer necessary as the equipment is the same. This includes, for example, measuring sensors, an internal coolant device, a coolant tank, a large tool magazine, a swivelling head with an extended swivelling area, a rotary table with a rotary plate and a partition for oscillating machining.

Oscillating machining means that the work area can be divided into two ranges using a partition. This allows two smaller work areas to be used independently of each other. The machine can first produce part A, and once the programme has run through, the spindle moves to the other side and continues with part B. "This means that I sometimes have a utilisation rate of almost 90 percent," says Holger Martin enthusiastically. Another plus point for him is the flexibility: "As a contract manufacturing company, we have different parts on the table every week - with a machine that can do a lot, we are naturally better installed."

For Managing Director Holger Martin, one thing is certain: "We will continue to work with HEDELIUS." He is interested in the 'ACURA' - a compact machining centre with automation. According to Martin, the shortage of skilled labour is a huge problem. And this machine can be loaded automatically using a pallet handling system and then run for several hours overnight or at weekends. This will enable the Hessian operation to remain competitive in the future.

HEDELIUS machining centres of the customer.

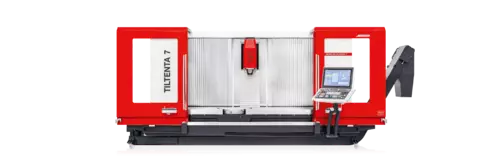

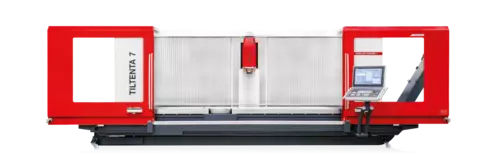

In accordance with market demand, HEDELIUS has designed the smallest size in the TILTENTA series to be significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.