Industry 4.0 in chipping.

On the way to the smart factory through digital networking.

The advancing digitalisation in the manufacturing industry is opening up completely new opportunities to make chipping processes more transparent, faster and more efficient. At HEDELIUS, we also take the increasing importance of intelligently linking production, quality and machine data seriously. The aim is to digitally support the entire value creation process, from order planning to the finished component.

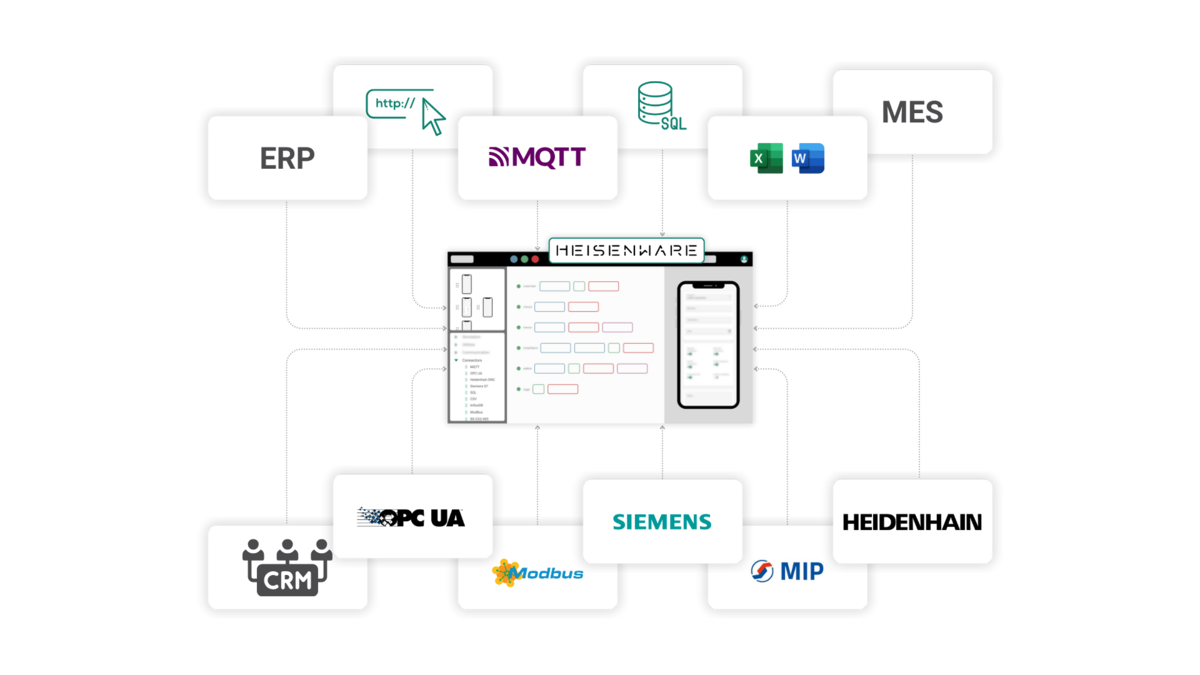

Seamless integration of different systems.

A crucial building block for this networked manufacturing environment is the integration of ERP, MES and CNC control systems. Open standards such as OPC-UA enable smooth data exchange between machines and company software. This means that order data can be automatically transferred to the machine control system, processing progress can be tracked in real time and quality and process indicators can be analysed directly.

More transparency, greater flexibility.

The continuous availability of data not only increases productivity, but also creates full transparency across the entire production process. Feedback on lead times, reject rates or machining output is available at all times and provides a sound basis for continuously optimising processes. Predictive planning and control options also allow bottlenecks to be recognised at an early stage and production processes to be flexibly adjusted.

Industry 4.0 at HEDELIUS

Future-proof production for sustainable success

At HEDELIUS, Industry 4.0 in chipping means installing future-proof production. With state-of-the-art technology and comprehensive process expertise, we support our customers in sustainably strengthening their competitiveness. The advantages are obvious: shorter lead times, greater efficiency, improved quality and maximum planning reliability - a decisive step towards meeting the constantly growing demands of the global market.

Heisenware as a reliable partner

In close cooperation with selected partners, HEDELIUS is expanding the digital value chain with customised software and integration solutions. Heisenware GmbH relies on a low-code integration tool that allows customised interfaces and data-based processes to be implemented quickly and flexibly.

As an expert in system integration and data management, Heisenware helps to seamlessly connect complex IT landscapes. From the development of customised interfaces to the transformation of order and machine data and the provision of cloud-based infrastructures: Heisenware offers comprehensive services to fully exploit the potential of Industry 4.0 and, together with HEDELIUS, to shape the manufacturing world of tomorrow.

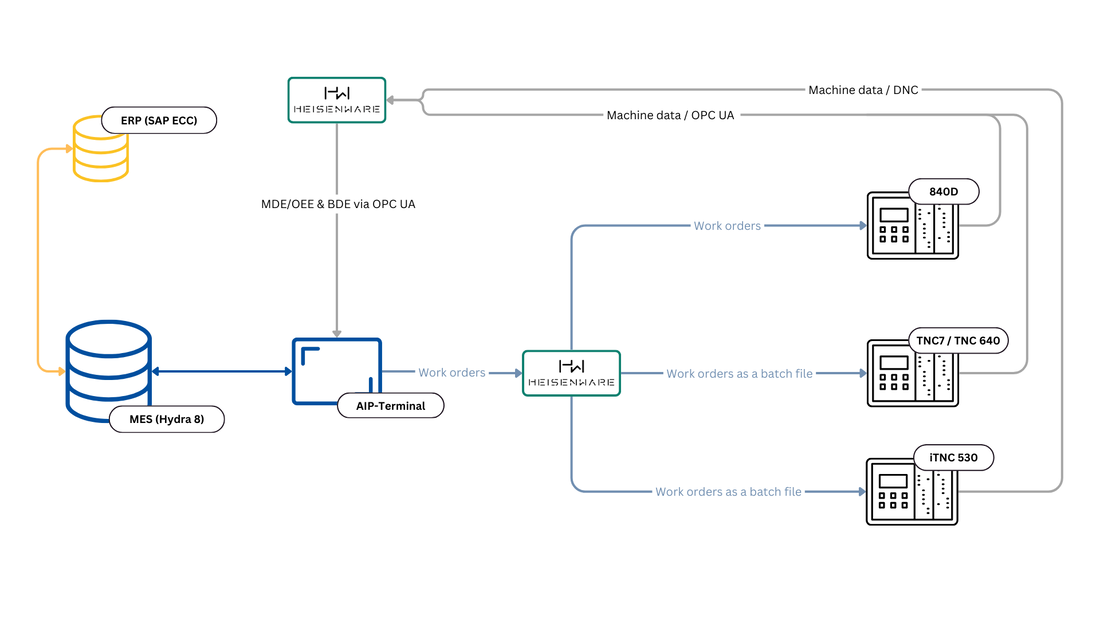

Example project from HEDELIUS production

Intelligent system integration: A reference project in HEDELIUS production

Advancing digitalisation has long been a decisive success factor for modern manufacturing companies. As a specialist in precision machining centres, HEDELIUS Maschinenfabrik plays a pioneering role when it comes to making internal processes more efficient, transparent and automated. A current digitalisation project is an example of how a future-proof Industry 4.0 ecosystem can be created through the seamless integration of ERP, MES and machine control systems with the help of OPC UA standards, supplementary software components and the expertise of Heisenware GmbH.

Vision and goals: Efficiency, automation and transparency

The centre of the project was the end-to-end, seamless automation of order processing and machine data processing. The primary goal was to transfer order data directly from the ERP system to the machine controls and, in turn, to transfer machine data back in real time. The complete digitalisation was intended to reduce manual data entry efforts, avoid media disruptions and enable seamless tracking of production progress.

OPC-UA: The technological foundation of digitalisation

The broad acceptance of OPC UA as a standardised, platform-independent communication standard in industrial automation facilitates the efficient networking of a wide variety of systems. By using OPC-UA, HEDELIUS was able to smoothly close ERP, MES and machine control systems with each other. The integration took place with the help of intelligent interfaces, which ensure that both data quality and data security are guaranteed at all times.

Digitalisation partner:

Heisenware GmbH

A key success factor in the project was the collaboration with Heisenware GmbH as a partner in terms of digitalisation and integration expertise. The company contributed a flexible low-code integration tool that enables customised adjustments and individual developments. The result was a middleware solution that not only simplifies the flow of data between machines and MES systems, but also ensures the safe, standardised exchange of information. This forward-looking infrastructure forms the basis for the further scalability and customisability of digital manufacturing processes - both internally at HEDELIUS and in future customer projects.

From vision to practice:

Successes and added value

The result speaks for itself: within just a few months, a digital end-to-end process was created that transfers order data to the machines without media disruptions and allows feedback to flow seamlessly back into the ERP and MES system. Thanks to this digitalisation, HEDELIUS is not only increasing efficiency, but also creating a basis for predictive production control, greater process stability and full transparency in real time.

Process diagram: Digital end-to-end process that transfers order data to the machines without media breaks and allows feedback to flow seamlessly back into the ERP and MES system

Industry 4.0 even without MES.

For smaller operating companies that do not use a complete MES, cost-effective solutions are available. Individual MES functions such as machine data acquisition for calculating and visualising the OEE or production data acquisition for direct feedback to the ERP can be implemented. In this way, production can be digitalised without incurring the high costs of a complete MES system.

Integration beyond OPC UA.

OPC UA is an excellent standard, but many machines in the field do not yet have this interface. Proprietary interfaces such as Siemens S7 or Heidenhain DNC can also be integrated to enable end-to-end digitalisation. In addition, the integration of serial interfaces and, in some cases, retrofitting is also possible in order to modernise existing systems.

Future security through Industry 4.0

With this flagship project, HEDELIUS is emphasising its claim to be able to offer customers not only first-class machine technology, but also holistic production solutions in line with Industry 4.0. The successful collaboration with Heisenware serves as an exemplary model for future digitalisation initiatives and opens up new perspectives for the continuous development of production processes and adjustment to changing market requirements.

Overall, the HEDELIUS digitalisation project shows how a well thought-out interplay of technology, process understanding and partner expertise lays a strong foundation for the industrial future - an important step on the open road to a fully networked, intelligently controlled manufacturing world.

More news

We will be on holiday from 21 July 2025 to 08 August 2025. Our service and sales team are still available for you.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!