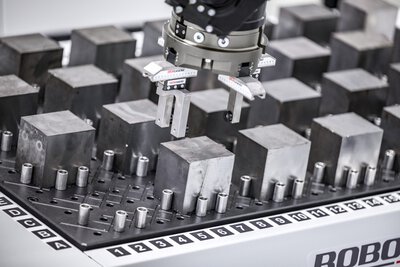

RoboJob Mill-Assist

This beginner-friendly automation system has been specially developed for tooling and unloading small series and/or small workpieces. The automation has a 6-axis robot that takes the workpieces from a fixed table and places them in the 5-axis machining centre of the ACURA series. Depending on the space available, the system can load the machine from the front or from the side.

Your advantages with the ROBOJOB MILL-ASSIST

- 6-axis robot with 25 kg load capacity

- Easily accessible

- Protection via floor scanner or protective fence

- Products customisable

- Graphical user interface for easy changeover

Get the best out of your production

Greater productivity, higher delivery reliability, relieved employees: there are many good reasons for automation in production.

Maschinenvergleich.

Fügen Sie weitere Maschinen hinzu um Leistungsparameter zu vergleichen.