Zero point clamping technology.

Simplify time-consuming set-up processes.

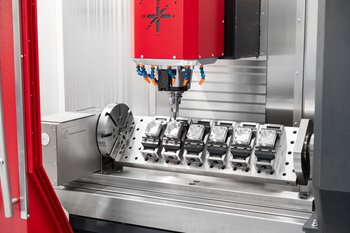

A zero point clamping system is an advantageous addition to a 5-axis machining centre. Numerous arguments from practice speak in favour of this.

Reducing non-productive times, setting up outside the machine, quickly slipping an urgent order in between. These challenges are part of everyday production. It is difficult to leave the beaten track here. The traditional clamping technology has grown too much with the respective machines over the years. A machine vice, a three-jaw chuck, the use of clamping claws and other clamping standards together with grooving or drilling systems are still indispensable in production. The disadvantage of these clamping devices, however, is that retooling the machine is very time-consuming.

Each time, at least 20, 30 or even more minutes are spent closing the clamping devices on the machine table in the tried and tested manner. First, the machine table is cleaned of chips and cooling lubricants, the existing device is dismantled, the machine table is cleaned again and then the new device is positioned. This is followed by the search for suitable clamping claws, screws, etc., in order to then fasten the device, run it several times with the dial gauge, align and finally fix it, and then check the position again with the dial gauge for safety reasons. The time required is considerable and often takes longer than the actual production time of the workpiece.

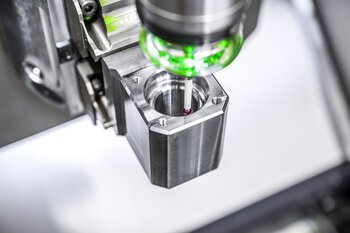

This is exactly where the idea of a zero-point clamping system comes in: The machine operator is provided with a means of simplifying time-consuming cleaning, measuring, aligning and clamping. The machine table is equipped with a standardised interface that reduces the centring and alignment of the device to just a few seconds. This eliminates a not inconsiderable source of error.

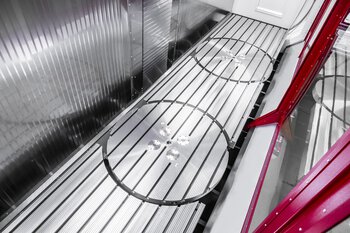

All HEDELIUS machining centres can be equipped at the factory with zero-point clamping systems from GARANT ZeroClamp or SCHUNK NSE. The clamping systems are installed flush in the fixed machine table, the integrated rotary table or the rotating/swivelling table so that the travel path is not restricted. The zero point clamping system impresses with its high holding force and repeat precision. Additional T-slots are still available for the use of classic clamping devices.