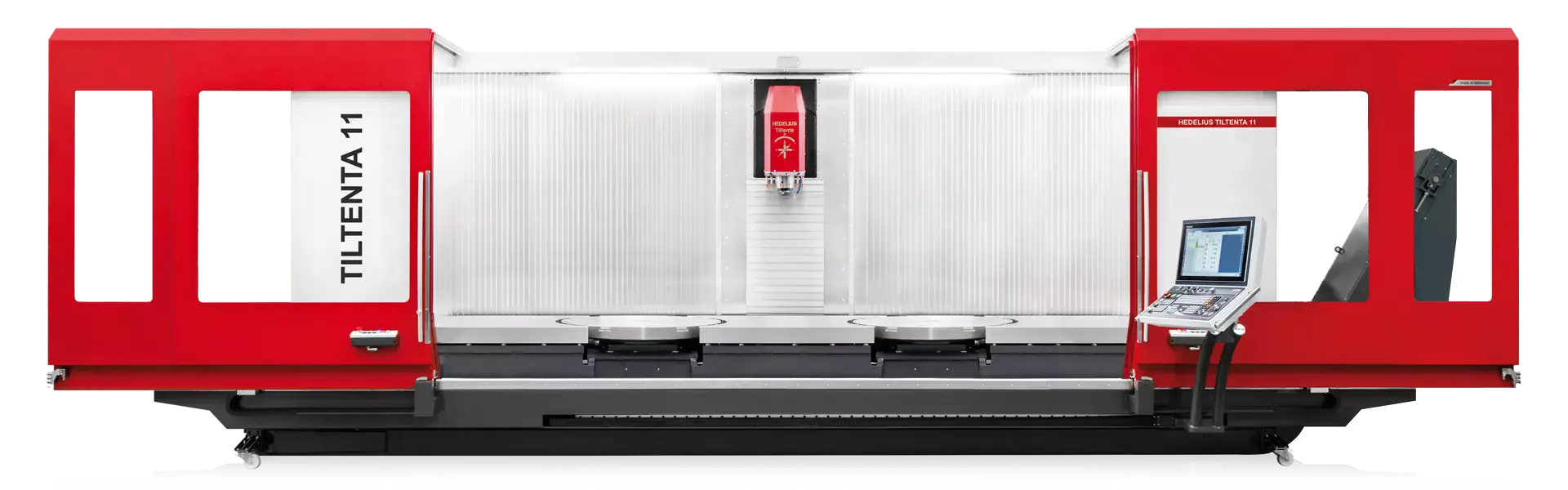

Machining centre with swivelling spindle: TILTENTA 11-4600

Thanks to the travelling tool magazine of the TILTENTA 11, tool changes only take a few seconds despite the 4600 mm travel path. The standard 65-cavity tool magazine already reduces your tooling times as standard. With a work area partition, the machine can also be loaded in oscillation mode during machining. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 5-axis machining centre.

Your advantages with the TILTENTA 11-4600

- Extra-large Y travel path of 1,100 mm

- Versatile 4/5-axis machining centre with swivelling main spindle

- High table load

- Optionally with integrated heavy-duty rotary table

- Maximum precision thanks to four axes in the tool and one axis in the workpiece

- Fast tool changer with 65 places

- Motor-activated automatic doors for high ease of use

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

Gallery.

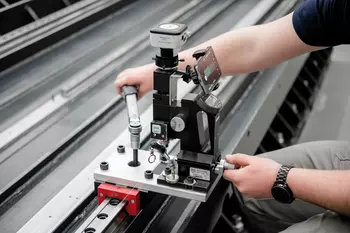

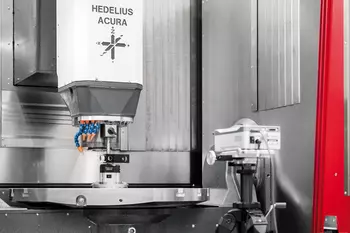

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.