Tooling optimisation - The key to increasing efficiency in production

Tooling optimisation is one of the most effective measures for increasing the efficiency of production processes and reducing costs at the same time. Particularly in single parts and small series production, where frequent retooling processes are required, reducing tooling times can bring significant economic benefits. HEDELIUS has set itself the task of providing solutions that minimise tooling times and maximise spindle running times. This article highlights the importance of tooling optimisation, its benefits and specific measures and technologies that contribute to its implementation.

Meaning of tooling optimisation

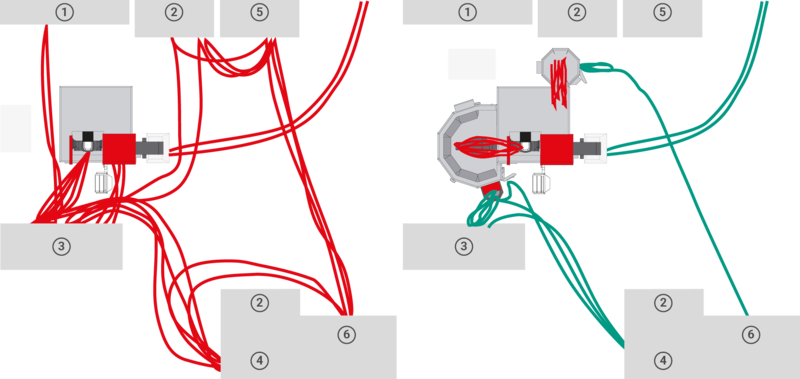

The tooling times describe the time required to open a machine from the production of one product to another. This includes processes such as device set-up, changing clamping devices and adjusting machining parameters. As these steps do not create any direct added value, they are often regarded as "unproductive" time. An effective tool for visualising inefficient movements in the set-up process is the spaghetti diagram. It identifies superfluous movements, long transport routes and avoidable time losses, thus creating a sound basis for process optimisation in production and process optimisation.

1 Chip clamping device | 2 Tool cabinet | 3 Workbench | 4 Measuring and testing station | 5 Presetting device | 6 Foreman's office/AV

Before tooling optimisation: Internal set-up processes are marked in red when the machine is stationary.

After tooling optimisation: External set-up processes are marked in green while the machine is working.

Challenges in practice

Advantages of tooling optimisation

Increased productivity

Shorter tooling times mean that the machine is available longer for the actual processing.

Cost reduction

More efficient utilisation of the machines and a reduced number of downtimes reduce production costs.

Flexibility

Faster changeovers allow a more flexible response to customer requirements.

Higher competitiveness

Companies can open up to market changes more quickly and have a competitive advantage.

Better resource utilisation

Personnel and machines are optimally utilised.

Improving quality

Standardised processes minimise errors and guarantee consistent quality.

Tool magazines as a decisive factor

One of the most effective measures for optimising the set-up process is the use of large tool magazines. These are of central importance for complex production orders and frequently changing machining orders.

Importance for the setup process

Minimisation of manual interventions

Tools that are set up once are available for multiple jobs. This reduces the frequency with which new tools have to be loaded manually.

Reduction of tooling times

The automatic tool change saves time as it is seamlessly integrated into the machining process. Especially for complex components with high tool requirements, there is no need for retooling during production.

Increase in machine availability

Large tool magazines allow continuous production without interruptions due to manual tool changes. This maximises the spindle running time.

Advantages of large tool magazines

Flexibility in production

Machines can perform a wide pallet of machining tasks without the need to change tools manually.

Increased automation

Combined with pallet changing systems and automation solutions, the entire production process becomes more efficient.

Quick response to order changes

Tools for various jobs are already available in the magazine and can be changed quickly if required.

Cost reduction

Saving tooling times reduces the production costs per unit.

Technologies and measures for tooling optimisation

HEDELIUS offers a range of innovative solutions to minimise tooling times and maximise production efficiency. The most important technologies and measures are described in detail below.

Zero-point clamping technology is one of the most effective methods for reducing tooling times. It enables fast, precise and repeatable positioning of workpieces.

Advantages:

- Significant reduction in tooling times.

- Height accuracy and repeat precision.

- Flexibility in the production of different workpieces.

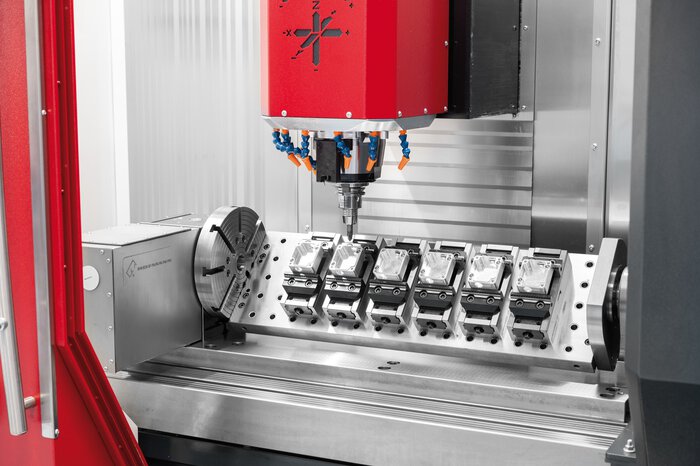

Automation solutions such as pallet changing systems help to further reduce tooling times.

Advantages:

- Machines can work without operator intervention.

- Ideal for series and small batch production.

- Higher spindle running times thanks to automatic workpiece changes.

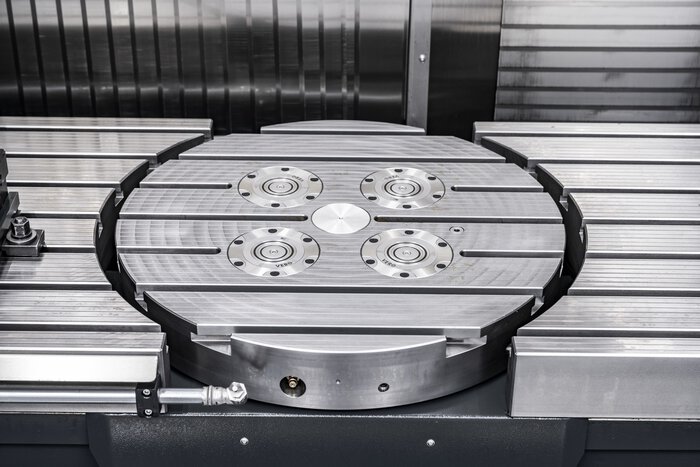

NC rotary tables extend the functionality of machine tools and enable flexible machining.

Advantages:

- Enable multi-sided machining.

- Reduce the number of set-ups required.

- Increase precision and productivity.

Swivelling bridges significantly expand the possible uses of machines and are particularly effective in multi-sided machining.

Advantages:

- Reduction of non-productive times.

- Possibility of multiple clamping.

- More efficient use of the machine.

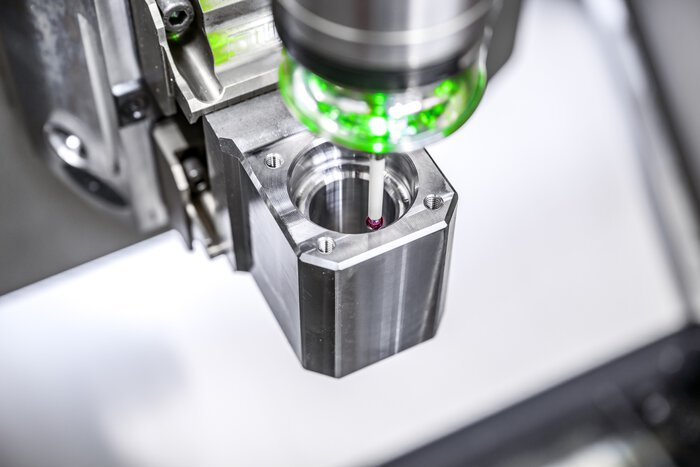

Measuring systems are crucial for ensuring precise machining and reducing tooling times.

Advantages:

- Fast and precise adjustment of tools and workpieces.

- Error prevention and greater process reliability.

- Support for quality control.

Well-trained personnel are an essential factor for the successful implementation of tooling optimisation.

Advantages:

- Personnel can work more efficiently.

- Better understanding of the machines and processes.

- Reduction of errors during set-up.

Standardising set-up processes is a cost-efficient and effective method of tooling optimisation.

Advantages:

- Unitised processes reduce errors.

- Shorter training times for employees.

- Increased efficiency thanks to clear specifications.

With the work area partition, the work area of a machining centre can be divided into two closed, independent ranges.

Advantages

- More efficient chipping in oscillation mode.

- Productivity is increased by working in parallel.

- Flexible machining of different workpieces.

The smart integration of the CNC control of the machining centre into the company network enables end-to-end digital production.

Advantages:

- Simplified work for employees.

- Time savings thanks to full data access from the control.

- Up-to-date data thanks to automated data exchange with various systems.

Your advantages with tooling optimisation

Tooling optimisation is an indispensable part of modern manufacturing. By using innovative technologies, standardised processes and well-trained employees, companies can increase their efficiency, reduce costs and improve their competitiveness. With solutions from HEDELIUS, companies have a reliable partner at their side to help them master the challenges of production and benefit from the advantages of tooling optimisation. We would be happy to present the various possibilities of tooling optimisation to you personally.