Clean tray capacity: 500 litres

Filtering level: 1.0 mm

Filter capacity: 180 litres/min

Pump output: 2.0 bar 150 l/min

Separate standing Coolant system with removable steel plate filter insert.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre. In this process, the coolant is fed through the work spindle directly to the cutting edges of the tool. As the use of cooling lubricants for lubrication, cooling and, in particular, chip removal is generally indispensable, this sub-system should be given special consideration when investing in a machining centre.

Find out more about our various cooling technologies and a wide range of expansion options below.

We offer our compact Coolant systems in three different versions. If the use of a centralised Coolant system is not possible, HEDELIUS offers an economical alternative with the inclined bed filter system. The inclined bed belt filters are characterised by a high filtering level and low paper consumption.

Clean tray capacity: 500 litres

Filtering level: 1.0 mm

Filter capacity: 180 litres/min

Pump output: 2.0 bar 150 l/min

Separate standing Coolant system with removable steel plate filter insert.

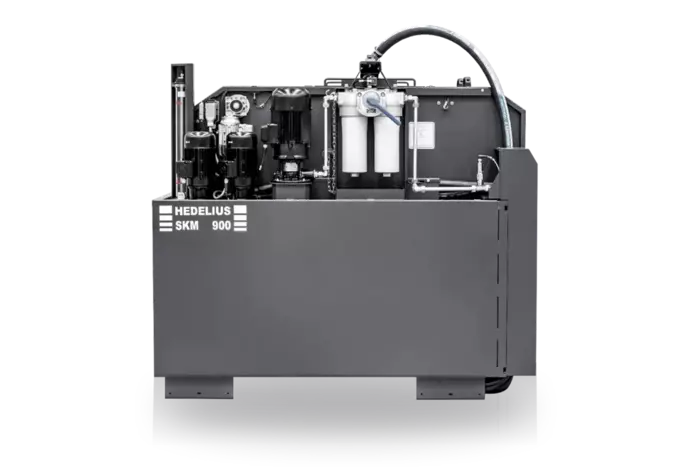

Clean tray capacity: 900 litres

Filtering level: 190 µm

Filter capacity: 180 l/min

Pump output: 2.5 bar 150 l/min

Separate inclined bed belt filter coolant system incl. automatic paper feed, fill level monitoring and steel sieve pre-filter above the filter felt for separating aluminium and plastic chips.

Clean tray capacity: 1400 litres

Filtering level: 190 µm

Filter capacity: 180 l/min

Pump output: 2.5 bar, 150 l/min

Separate inclined bed belt filter coolant system incl. automatic paper feed, fill level monitoring and steel sieve pre-filter above the filter felt for separating aluminium and plastic chips.

With the help of a wide range of additional equipment options, a Coolant system can be customised to your individual machining task. For example, an immersion cooler offers a high level of process reliability thanks to the active and controlled cooling of the lubricant by counteracting heat input into the material and tool. A belt skimmer for separating floating oils prevents contamination of the coolant. Furthermore, equipping the system with additional sensors can significantly simplify time-consuming maintenance work.

**For maximum accuracy

An immersion cooler with integrated agitator keeps the coolant temperature constant. This not only increases the service life of the cooling lubricants, but also benefits the accuracy of the milling process.

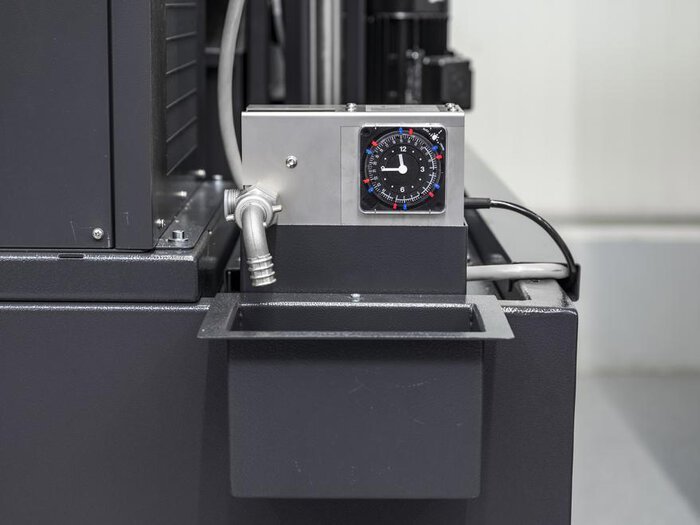

**For sustainable oil separation

Optimal is the connection of the agitator with an integrated oil skimmer. Thanks to the separate power connection, the cooler, agitator and skimmer also run during non-production times, e.g. at weekends or on public holidays.

**For improved coolant maintenance

The optional equipment of the Coolant systems with digital sensors for measuring concentration and temperature considerably simplifies coolant maintenance.

**For greater process reliability

Depending on the application, the systems can also be equipped with high-pressure pumps of 25, 50 or 75 bar. By supplying coolant under high pressure, the tool edges are cooled and wear is avoided.

**For optimum machine performance

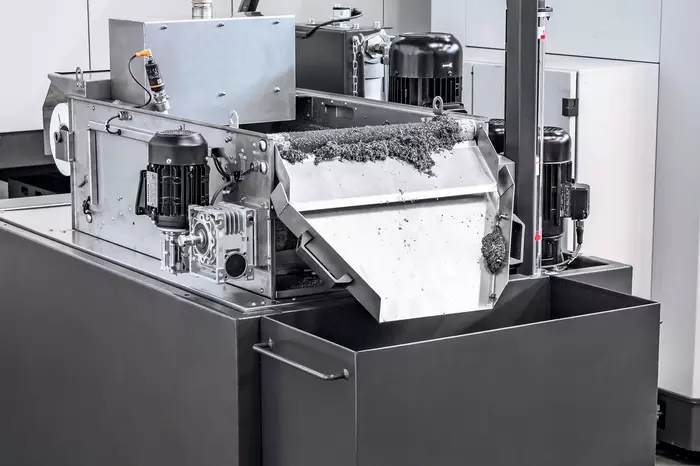

The separate belt filter Coolant system is equipped with a belt scraper that removes aluminium and plastic chips from the belt and discharges them into a separate chip accumulation container. This ensures efficient cleaning and removal of the chips.

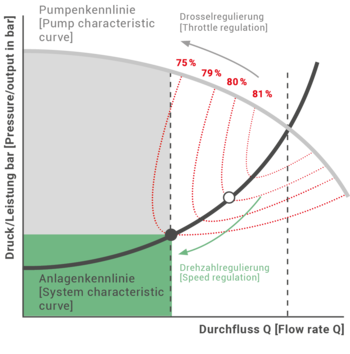

In conjunction with an internal high-pressure coolant supply, a frequency converter is installed as standard to control the speed of the pump. As not every tool or process requires the full pressure, the coolant pressure and therefore indirectly the energy consumption can be set individually for each tool directly in the NC programme using the speed control. As a rule of thumb:

20% speed reduction leads to 50% energy savings

50% speed reduction leads to 80% energy savings

HEDELIUS also offers a user-friendly and sustainable solution when it comes to recycling coolants. By connecting a chip press to your machining centre, the chips produced in the chipping process are separated from the cooling lubricants. The adhering cooling lubricants are almost completely pressed out of the chips and returned to the chip conveyor. In addition, the volume of the chips produced is reduced by up to approx. 80 % during the briquetting process. This allows you to produce profitable recyclable materials from waste materials that are to be disposed of.

for CNC machining centres

Machining centres direct from the manufacturer. Very short delivery time!

Find the right CNC machining centre for you.

X: 500 mm | Y: 550/370 mm | Z: 550 mm

Ø 550 mm Sturgeon circuit | max. 300 kg

SK40 / BT40 / HSK A63

X: 700 mm | Y: 650/465 mm | Z: 600 mm

Ø 700 mm Sturgeon circuit | max. 500 kg

SK40 / BT40 / HSK A63

X: 900 mm | Y: 850/600 mm | Z: 700 mm

Ø 900 mm Sturgeon circuit | max. 1000 kg

SK40 / BT40 / HSK A63

X: 2000/2600/3600 mm

Y: 700 mm | Z: 695/735 mm

Ø 1050 mm Sturgeon circuit | max. 800 kg

SK40 / BT40 / HSK A63

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 900/1005 mm

Ø 1250 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1000/1165 mm

Ø 1450 mm Sturgeon circuit | max. 2200 kg

SK50 / BT50 / HSK A100

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 900/1005 mm

Ø 1450 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

X: 1120 mm | Y: 550 mm | Z: 550 mm

SK40 / BT40 / HSK A63

X: 1320 mm | Y: 650 mm | Z: 600 mm

SK40 / BT40 / HSK A63

X: 1620 mm | Y: 850 mm | Z: 700 mm

SK40 / BT40 / HSK A63

X: 2000/2600/3600 mm

Y: 700 mm | Z: 800 mm

SK40 / BT40 / HSK A63

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1165 mm

SK50 / BT50 / HSK A100

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

Increase the accuracy of your production with the help of advanced touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Ensuring a technological edge: High-output and high-torque CELOX integral motor spindles with hybrid bearing technology.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

Automation solutions and open interfaces for third-party providers to increase efficiency.

Automation solutions for single parts as repeat parts or small to medium series with pallets.

Robot cells manage workpieces from grid drawers fully automatically for small and medium batch production.

Automation solutions that combine workpiece and pallet handling in one system

Mirror-image version of the ACURA 50 and ACURA 65 enables interlinking with pallet or workpiece systems.

Separate tool stores for up to 264 additional tools clean, maintain and reduce changeover times enormously.

Preconfigured standard interfaces, e.g. for EROWA, INDUNORM, ROBOJOB, BMO or LANG, are available for the electrical connection to an automation system.

+ Automation of machining centres with rotating/swivelling table

+ Lateral loading by the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

+ Automation of long-bed milling machines with swivelling spindle

+ Front loading through the automation system

+ Work area remains intact

+ Solution for 5-axis and long part machining

+ Automation of 3-axis milling machines

+ Lateral loading through the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

With over 3,000 HEDELIUS machining centres installed today, we ensure precise and powerful chipping in a wide range of industries.

Various design highlights ensure that our customers can achieve maximum precision and efficiency in every production step in the long term.

By using set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can maximise their spindle running time in the long term.

The factors that have a significant influence on the accuracy of our precision machines.

Optimise your HEDELIUS machining centre with a wide range of optional features that are precisely tailored to your specific requirements and production tasks.

Increase the accuracy of your production with the help of highly developed touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Technologischen Vorsprung sichern: Leistungs- und drehmomentstarke CELOX-Integral Motorspindeln mit Hybrid-Lagertechnik.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

The TNC7 combines high-quality hardware components with an advanced, customisable user interface and a generous package of functions.

With SINUMERIK ONE, you can set new standards in your production thanks to digital twins, extended diagnostic functions and a high degree of flexibility.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

We provide a wide range of free information material in our download area.

All upcoming dates for workshops, trade fair appearances and other events at a glance.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of HEDELIUS machines.

Interesting facts about the company, news, product information, user reports

For 55 years, HEDELIUS has had only one goal: to increase economic efficiency in single parts and small series production in machine, tool and vehicle construction.

Take the opportunity to experience our machining centres and automation solutions live and see their performance and safety for yourself.

Thousands of companies in Europe, including hidden champions, rely on our solutions. From SMEs to global corporations, we accompany you on the path to sustainable success.

Comprehensive and practical training for CNC programmers and operators from 3-axis to 5-axis machining.

Experience the latest developments in machining technology - either conveniently online or directly with us in Meppen.

HEDELIUS brand machining centres are used in a wide range of industries.

Conserving resources, energy efficiency and safeguarding the future: our efforts to make a positive contribution to shaping a sustainable future.

As a supplier, do you share our values of quality and reliability? Then please feel free to open a dialogue with us.

Over the years, we have built up a strong network of 17 trading partners throughout Europe.