BL Lasertechnik GmbH | TILTENTA 11-4600; FORTE 85; MARATHON PL406; ACURA 65 MARATHON; ACURA 85

Field of application: Metalworking, contract manufacturing | Company headquarters: Neuschönau, Germany | Employees: 100

This video requires your consent to third-party cookies. Privacy settings

Further informationStronger than ever before: BL Lasertechnik turns fire disaster into a success story

The sight is despairing: huge flames destroy two production halls with valuable machines in a very short space of time. Nothing remains but rubble and ashes. Was this the end of BL Lasertechnik GmbH in Neuschönau, Bavaria?

The company specialises in laser cutting, bending and welding work. It is regarded as a model company in the Bavarian Forest and, according to a report in the Passauer Neue Presse, recently landed a major order from Deutsche Bahn.

Like a phoenix rising from the ashes.

The company briefly hesitated about whether to make a fresh start, says managing director Max Bauer. But just one day later, the decision was made: "We're going ahead!"

With quick and unbureaucratic help from friendly companies, this was also successful. This included the Emsland-based company HEDELIUS, which proved to be a reliable partner in the company's hour of need. Machines were delivered in the shortest possible time so that production could be quickly resumed at the company's second, new location.

HEDELIUS hall with six machines.

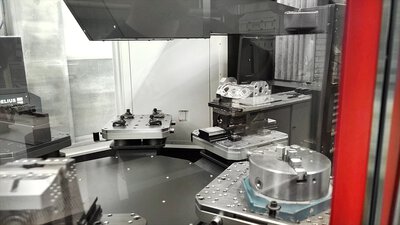

Today, six HEDELIUS machines are available for all machining tasks, including two 5-axis machining centres from the ACURA series with rotating/swivelling table. Moritz Sammer is the operator of an ACURA 65 MARATHON. He raves about the uncomplicated operating of the machining centre and the fact that "the components are brought into the machining process from several pallets. Clamp them once and the ACURA 65 does the rest virtually automatically."

"Flexibility is a very big factor," says Technical Manager Maximilian Scharringer. "We are very broadly installed as far as our customers are concerned, whether single parts or series production. In addition to milling, edging and welding, we also offer powder coating."

Automated production solution from a single source.

The ACURA 65 with travel paths of 700 x 650/465 x 600 mm is connected to a MARATHON pallet automation system of type PL406, also from HEDELIUS, meaning that machine and automation are perfectly harmonised: Automated loading of the machining centre with the pallets takes place via a side opening, which means that the work area remains accessible from the front and from above at all times for single part production during the day shift. The consistent Heidenhain operating concept on the machine and automation ensures convenient, simple operating. The Schunk Vero NSA zero-point clamping systems installed at the factory save valuable tooling times for each part.

15 minutes time saving - per workpiece.

This efficiency is omnipresent in the HEDELIUS hall. A few metres away from the ACURA 65, a large component for an excavator shovel is being machined. "We purchased the TILTENTA 11-4600 2R with two rotary tables for jobs like this. This saves us 15 minutes per workpiece. That's great."

The large TILTENTA shines as a true all-rounder in the machine park of BL Lasertechnik GmbH. Equipped with an extra-large Y travel path of 1,100 mm, a collision area diameter of 1,450 mm, a CELOX liquid-cooled motor spindle and two integrated heavy-duty rotary tables, the swivelling spindle machining centre is particularly useful for the powerful and precise production of large, heavy and complex components. In addition to the large machine, two smaller 5-axis machining centres from the TILTENTA swivelling head series and a vertical 3-axis machining centre of the FORTE 85 Single 1620 type are available for a wide range of machining tasks.

Reliable technology - satisfied employees.

Scharringer knows his employees - it is very important to him that they are satisfied. This includes the entire working environment. "And if the machine, if the operating functions smoothly, then that's half the battle."

BL Lasertechnik GmbH now has 120 employees at its two sites in Neuschönau and Philippsreut - more than before the fire. Many of them know Meppen in Emsland, where HEDELIUS Maschinenfabrik is based, from their CNC training. This is another way to build trust. The only thing they don't know so well in Bavaria is HEDELIUS' emergency service, says Scharringer: "We simply don't have the negative experiences."

HEDELIUS machining centres of the customer.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.