Accessories & optional features.

With our wide range of accessories and numerous options, our customers can perfectly adjust their CNC machining centre to their individual needs and requirements. By optimising your machining centre in accordance with your production requirements and goals, you can reduce downtimes, cut costs and increase efficiency in the long term.

Get an initial overview of our wide range of optional features and accessory solutions. Our technical experts will be happy to advise you to find a customised CNC solution from HEDELIUS that will help you to make optimum use of your resources and ensure your success in the long term.

What is usually considered special accessories is standard at HEDELIUS: All machining centres are equipped with a CNC full keyboard, colour monitor, spindle feed overdrive and original software as standard. State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum ease of use and unrestricted functionality. You decide which system you want to work with.

Heidenhain TNC 7

The new HEIDENHAIN TNC 7 control system focuses on intuitive, task-orientated and individual control. A customised user interface provides the user with optimum support in every situation. Familiar HEIDENHAIN programming functions are supplemented by smart functions. The control elements of the TNC keyboard are retained, providing a solid basis for the control of HEDELIUS machining centres.

Sinumerik ONE

The SIEMENS SINUMERIK ONE control system brings your ideas to life. SINUMERIK ONE is the future-oriented CNC system for highly productive HEDELIUS machining centres. For unimagined new possibilities, ideas and business models. For faster innovations thanks to the seamless interaction between the virtual and real worlds. And: SINUMERIK ONE is far more than just a powerful hardware innovation.

portable control unit

An external portable control unit has an electronic hand wheel and several axis and function buttons. This allows you to control the axes or set up the machine at any time and in any place, enabling flexible and efficient operating.

Optimising setup times is crucial in order to close efficiency and competitiveness in chipping. By using standardised processes and set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can reduce unit costs, save resources and increase flexibility. This not only enables improved machining output, but also efficient production of small batch sizes with consistently high quality. HEDELIUS supports manufacturing companies with a wide range of solutions and innovative technology to help them close these gaps.

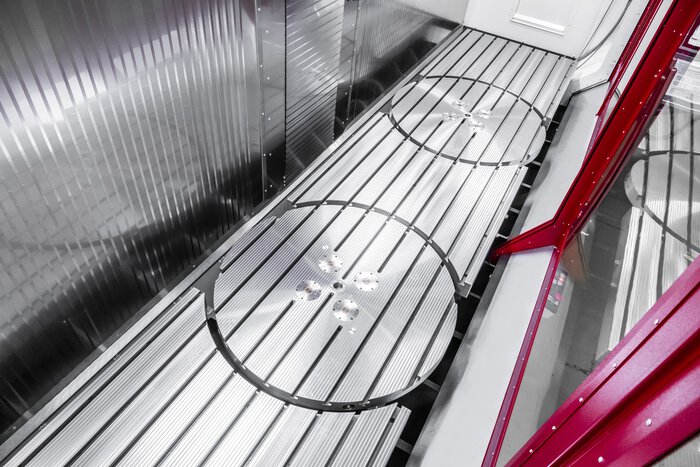

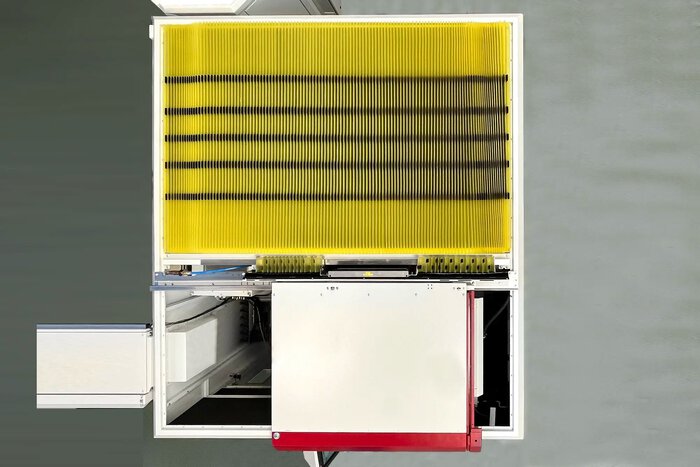

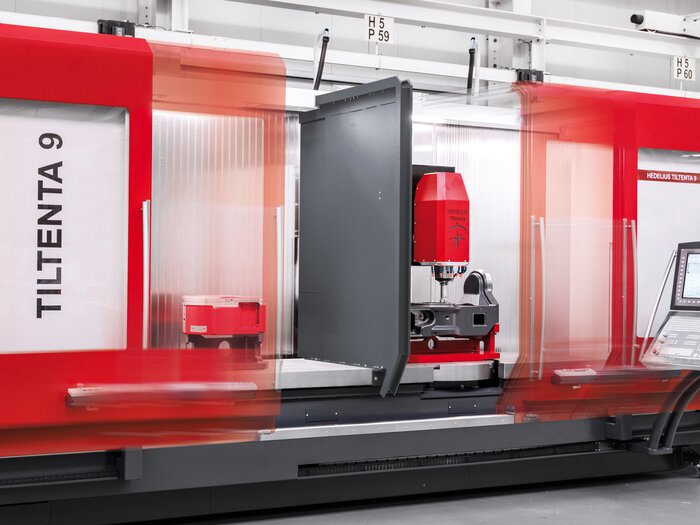

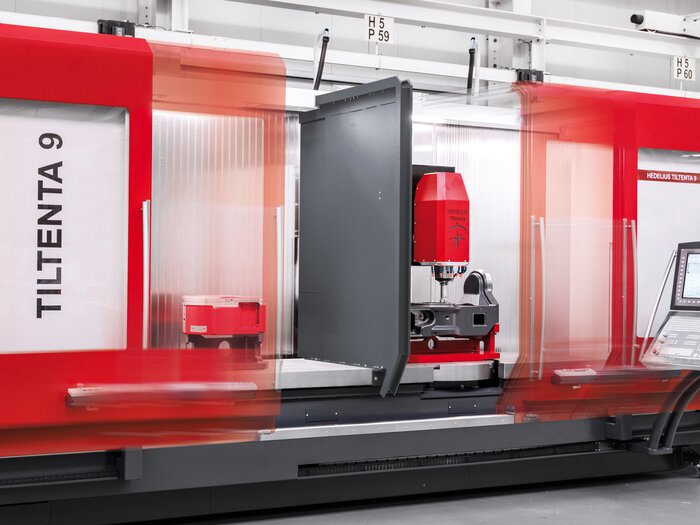

work area partition

By using a work area partition in the machining centre, two closed, independent work areas for economical chipping in oscillation mode can be created from one work area of the machine. The partition can be inserted or removed in just a few minutes.

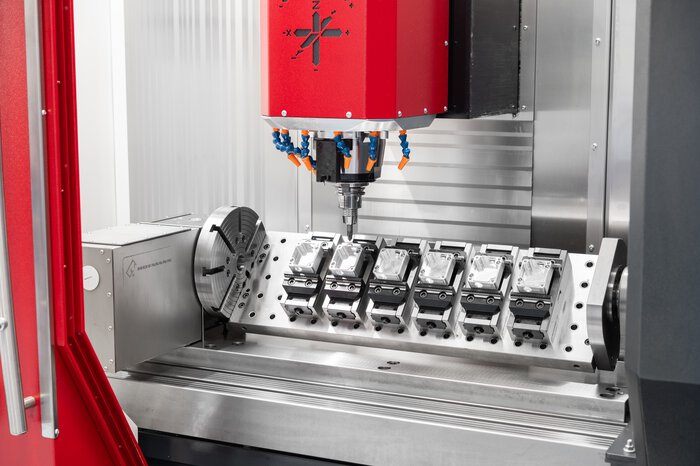

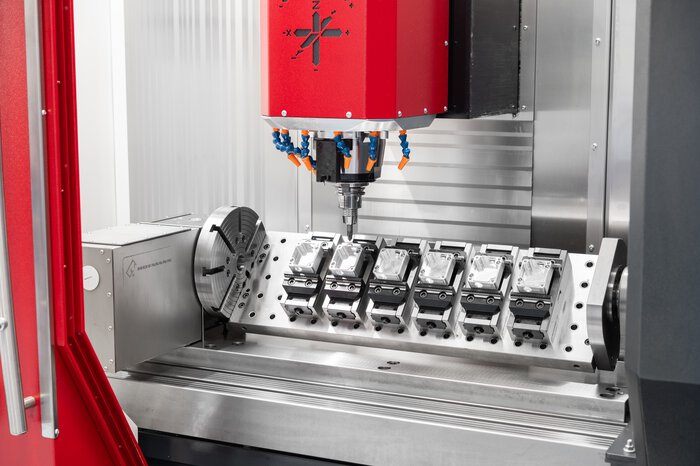

Zero point clamping technology

HEDELIUS machining centres can be equipped with zero-point clamping systems from GARANT ZeroClamp or SCHUNK NSE. With the help of this standardised interface, you can achieve a significant reduction in non-productive times by simplifying time-consuming cleaning, measuring, alignment and clamping.

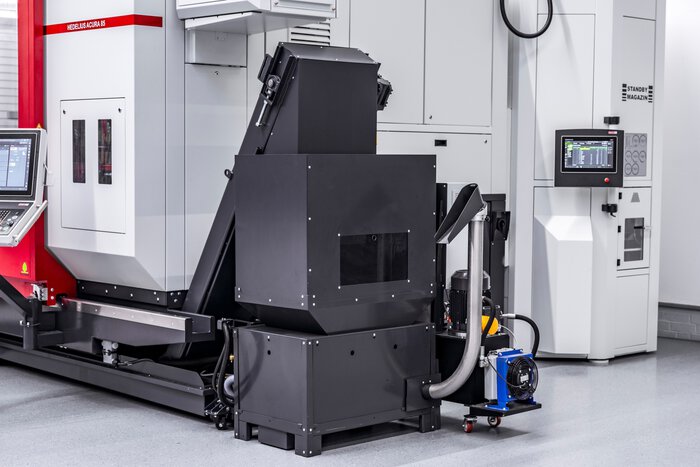

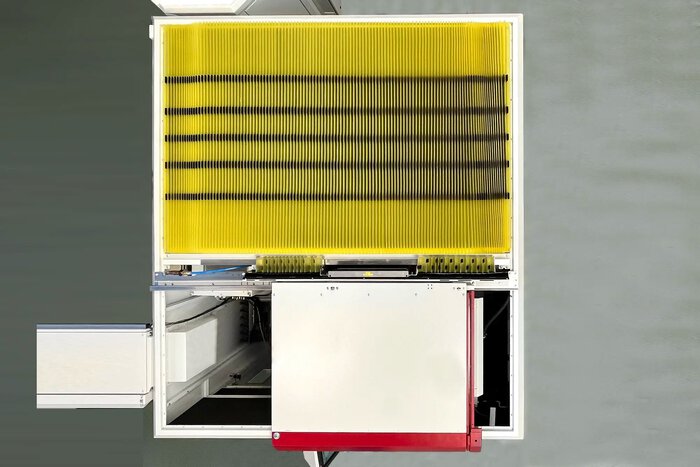

STANDBY tool magazine

The STANDBY tool magazine offers you the choice of 152, 180 or 264 additional tool spaces. With its minimal dimensions of 2810 mm in height and a base area of 1340 mm in diameter, the STANDBY MAGAZIN combines maximum productivity with minimum space requirements.

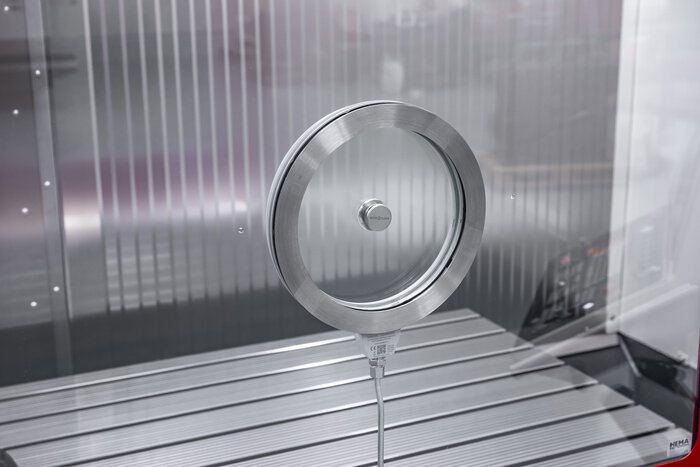

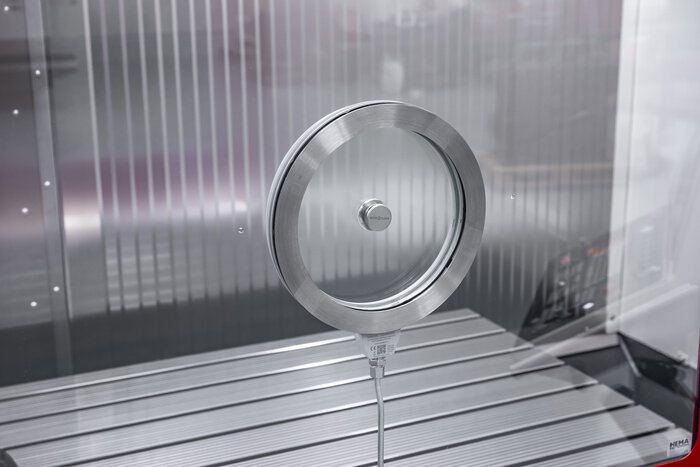

3D workpiece touch probes

The area of application of a 3D button ranges from preparatory measurements, such as determining the allowance, to regulating measurements during chipping, such as readjusting fits, to monitoring measurements at the end of the program to create reports.

Mechanical button

As standard, HEDELIUS relies on the proven IRT35.70 infrared tool measurement system from m&h for milling machines and machining centres. Tool measurement and tool breakage detection can be carried out flexibly with just one device - even on machines with oscillating machining.

Laser measuring bridge

Non-contact tool measurement using a laser beam not only enables precise and non-contact measurement of length and diameters, but also automatic control of tool wear or breakage.

drill breakage control

On the ACURA models, HEDELIUS offers fast breakage detection for drills and taps integrated into the tool magazine. After each tool change, the drill or tap is probed with a wand to check the length stored in the tool table. The measuring process only takes approx. 3 seconds and is therefore significantly faster than measuring using a button or laser.

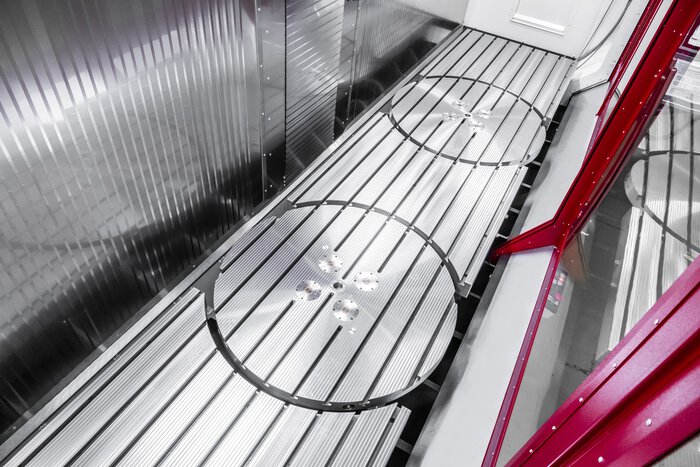

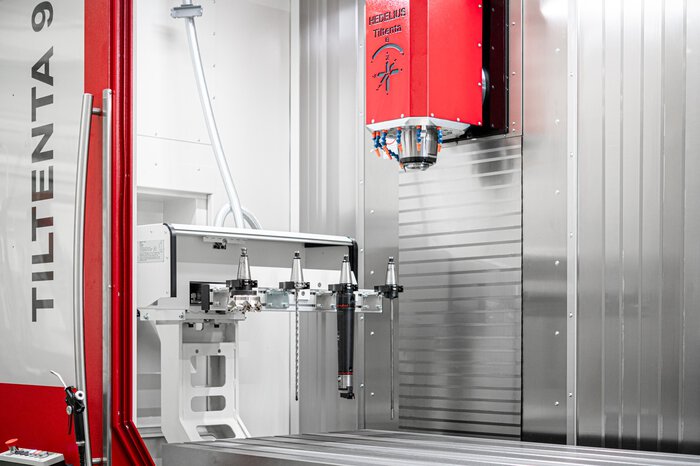

Integrated heavy-duty NC rotary tables

The NC rotary tables installed flush with the machine table extend the range of applications of your TILTENTA CNC milling machine from 5-sided machining to 5-axis simultaneous processing. The clamping weights range up to 1800 kg.

NC rotary tables and clamping systems

The extensive range of accessories for HEDELIUS travelling column machining centres considerably expands the range of applications for the machines. NC rotary tables for 4-sided machining or swivelling bridges with counter bearings can be integrated into the spacious work areas. As an option, the HEDELIUS machines can be equipped with a zero point clamping system, which is installed in the machine table at the factory.

Swing bridges

Swivel bridges driven by an NC rotary table enable multi-sided machining with multiple clamping and thus rationalise series production. Multiple clamping drastically reduces the machine's non-productive times, as the chip-to-chip time, for example, is divided between the individual clamping nests.

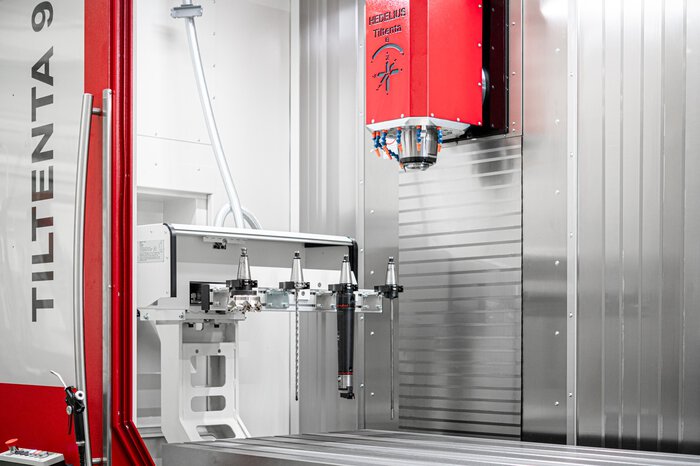

Pick-up magazine

When using very long tools such as deep hole drills or tools with a large diameter such as disc cutters or spindle tools, the pick-up magazine is the solution. The magazine is mounted on the side of the machine table and offers space for up to 4 tools. The maximum tool diameter is 210 mm and the maximum tool length is 600 mm.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre. In this process, the coolant is fed through the work spindle directly to the cutting edges of the tool. As the use of cooling lubricants for lubrication, cooling and, in particular, chip removal is generally indispensable, this sub-system should be given special consideration when investing in a machining centre.

Coolant system SKM 500

Clean tray capacity: 500 litres

Filtering level: 1.0 mm

Filter capacity: 180 litres/min

Pump output: 2.0 bar 150 l/min

Separate standing Coolant system with removable steel plate filter insert.

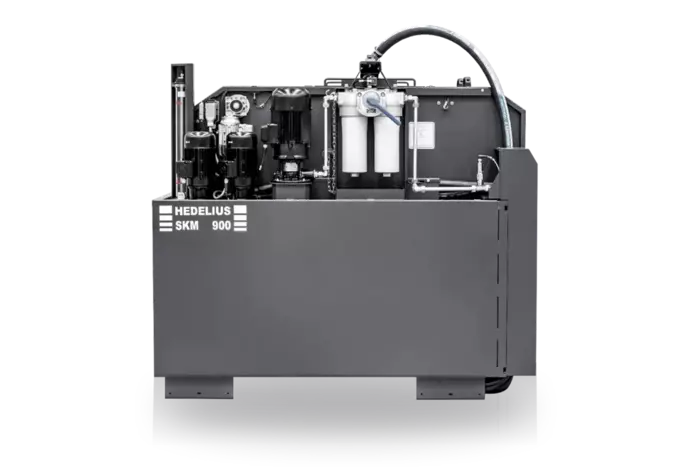

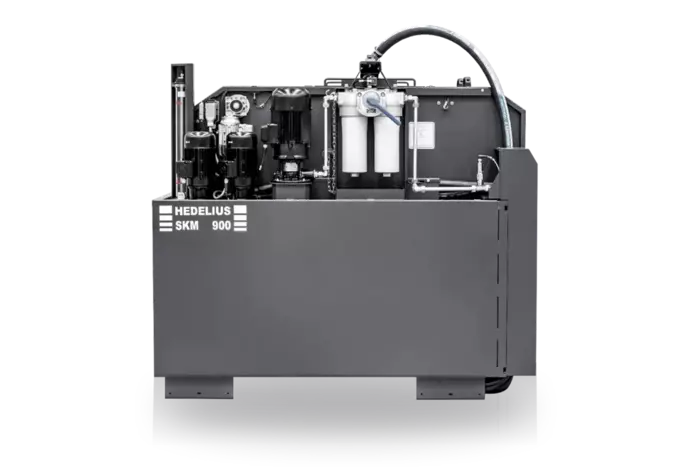

Coolant system SKM 900

Clean tray capacity: 900 litres

Filtering level: 190 µm

Filter capacity: 180 l/min

Pump output: 2.5 bar 150 l/min

Separate inclined bed belt filter coolant system incl. automatic paper feed, fill level monitoring and steel sieve pre-filter above the filter felt for separating aluminium and plastic chips.

Coolant system SKM 1400

Clean tray capacity: 1400 litres

Filtering level: 190 µm

Filter capacity: 180 l/min

Pump output: 2.5 bar, 150 l/min

Separate inclined bed belt filter coolant system incl. automatic paper feed, fill level monitoring and steel sieve pre-filter above the filter felt for separating aluminium and plastic chips.

Other optional features for cooling and lubrication.

Immersion cooler

**For maximum accuracy

An immersion cooler with integrated agitator keeps the coolant temperature constant. This not only increases the service life of the cooling lubricants, but also benefits the accuracy of the milling process.

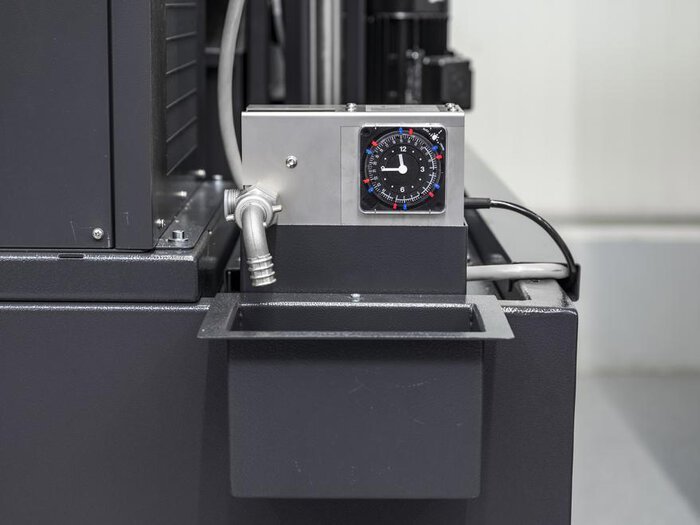

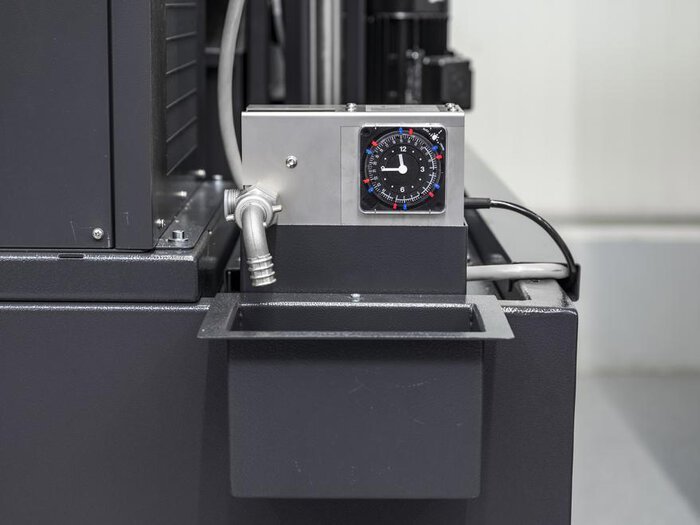

Oil skimmer

**For sustainable oil separation

Optimal is the connection of the agitator with an integrated oil skimmer. Thanks to the separate power connection, the cooler, agitator and skimmer also run during non-production times, e.g. at weekends or on public holidays.

Concentration and temperature sensor

**For improved coolant maintenance

The optional equipment of the Coolant systems with digital sensors for measuring concentration and temperature considerably simplifies coolant maintenance.

Internal coolant supply

**For greater process reliability

Depending on the application, the systems can also be equipped with high-pressure pumps of 25, 50 or 75 bar. By supplying coolant under high pressure, the tool edges are cooled and wear is avoided.

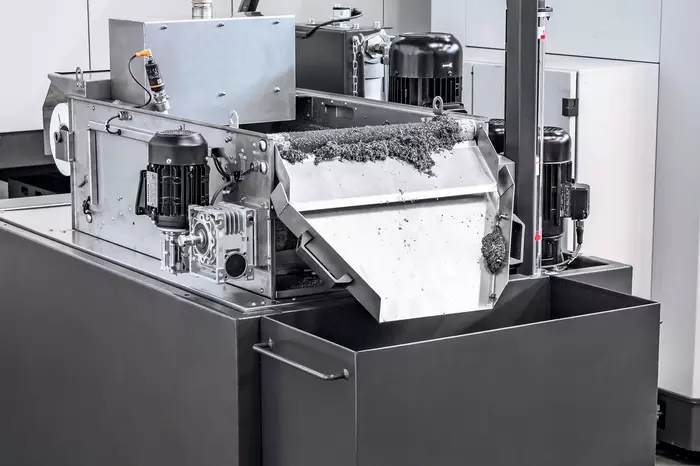

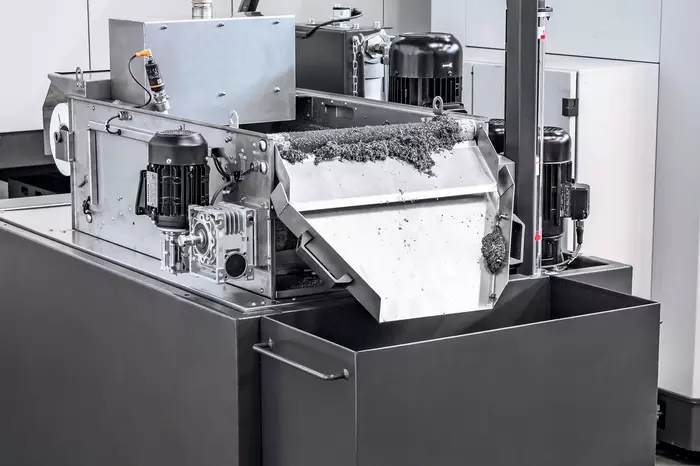

Belt filter Coolant system with belt scraper

**For optimum machine performance

The separate belt filter Coolant system is equipped with a belt scraper that removes aluminium and plastic chips from the belt and discharges them into a separate chip accumulation container. This ensures efficient cleaning and removal of the chips.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres. By using special technologies to effectively remove chips and cooling lubricant residues, you can ensure a clean working environment that not only increases the precision of your machining operations, but also extends the service life of your machine.

exhaust air filters

Fully enclosed with electrostatic LTA exhaust filter incl. mechanical pre-filter/follow-up filter and electrostatic filter.

Chip flushing device

In addition to manually activated blow-off and rinsing pistols for removing chips and blowing workpieces dry, the CNC machining centres can also be equipped with additional rinsing nozzles, which increases process reliability, particularly in automated production and aluminium production.

rinsing pistol

Equipping the machine with a rinsing pistol, complete with coolant pump and holding device.

Installation in the work area on FORTE and TILTENTA, installation outside the machine on ACURA.

dust protection cladding

Fully encapsulated rear machine room for dust protection of the travelling column and the complete X-axis.

side-hung window

Built-in side-hung windows in your CNC milling machine are an active safety precaution. They guarantee the machine operator a direct view of the processes in the machine and ensure increased safety, especially when running in new workpieces.

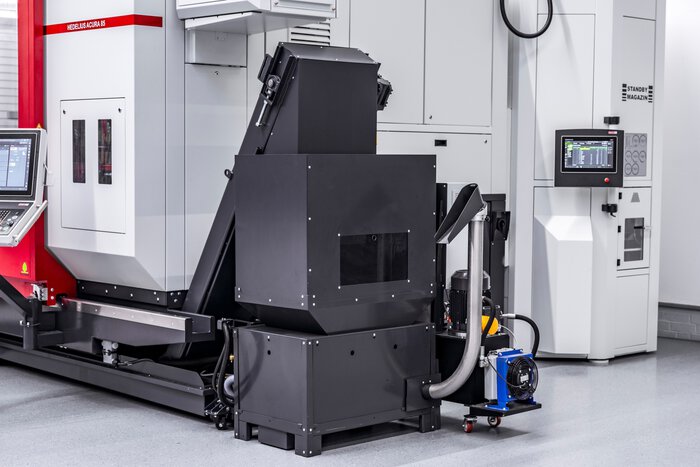

chip press

A chip press, which is connected to your CNC machining centre, separates the chips from the cooling lubricants and compresses them into clean, manageable briquettes. This reduces logistics costs, saves valuable resources, generates additional revenue and protects the environment.

Learn more

Customised paint finish

Whether classic red, elegant white, bright blue or neutral anthracite - determine the appearance of your new machine to match your company and make a statement to your employees and customers as a modern manufacturing company.

Learn more

Automatic doors

Motor-activated workspace doors on your CNC milling machine increase ease of use for your employees. Automatic doors are particularly recommended for short workpiece runtimes to reduce the workload on your employees.

Learn more

Liquid-cooled motor spindles

HEDELIUS uses liquid-cooled direct drive spindles, so-called motor spindles, in its machining centres. You have the choice between different spindle designs from 8,000 to 24,000 rpm with outputs of up to 50 KW, as well as between SK or HSK variants.

Learn more