WFT Werkzeug- und Frästechnik GmbH | ACURA 65 EL with INDUMATIK Light 120

Field of application: Plastics technology | Company headquarters: Delligsen, Germany | Employees: 58

Experts for the big and heavy.

WFT Werkzeug- und Frästechnik GmbH specialises in the precise production of pre-series and series tools for the plastics processing industry. The company's example impressively demonstrates what can be achieved with the right automation solution - and why employees also benefit from it.

WFT GmbH's machinery covers a total area of 3,000 square metres. Two massive overhead travelling cranes are "enthroned" above it, both with a lifting capacity of 25 tonnes each - making a total of 50 tonnes. "That's how much the heaviest tools we produce here weigh," says Operations Manager Heiko Siebke, categorising the enormous production dimensions.

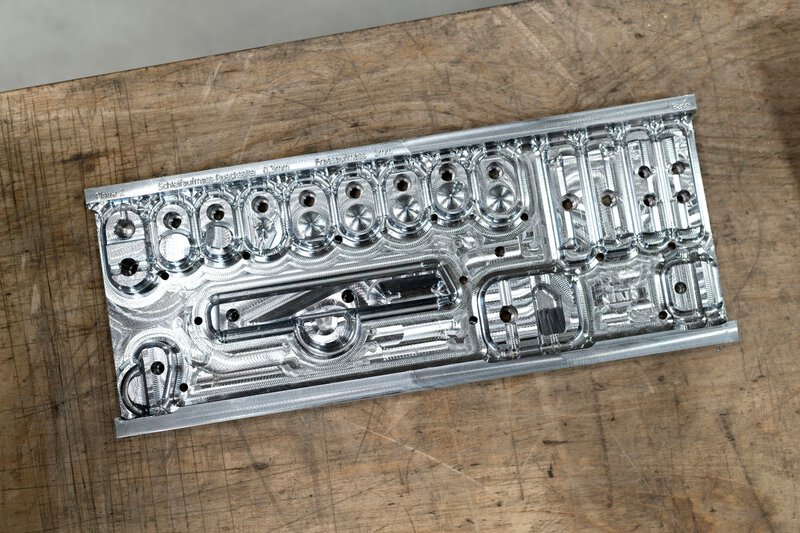

The fact that the compact HEDELIUS ACURA 65 EL is by no means the largest machining centre in the company's halls should come as no surprise to anyone. However, the production possibilities offered by the compact machine in combination with the Indumatik Light 120 pallet automation system are something that WFT would be open to.

Fourth generation family business.

WFT GmbH was founded in 1997 in Delligsen, around 40 kilometres south-west of Hildesheim. However, the company's roots go back even further, to the Hanseatic city of Hamburg. There, over 100 years ago, in 1919, master model maker Hermann Lühr founded the GmbH named after him, which was dedicated to the construction of foundry models for the machine and shipyard industry. From the 1970s onwards, the company increasingly invested in modern CNC technology and CAD/CAM systems and, as a result, expanded its production range.

As a second pillar of the Hamburg-based company, the newly founded WFT GmbH was to focus on toolmaking and chipping from the end of the 1990s - with great success. Today, its customers include the automotive industry, air and aerospace companies, medical technology companies and their suppliers. Stefan Lühr is the fourth generation of the family to run the company, which currently employs 58 people.

Automation: "Not a decision you make overnight."

Many users are initially sceptical about the idea of automating their own production, especially when it comes to practicality.

At WFT, too, the purchase was preceded by detailed considerations and deliberations: "We prepared intensively for the automation. It's not a decision you just make overnight," emphasises Siebke.

He and Stefan Lühr are all the more satisfied with their decision in favour of the automation concept presented by HEDELIUS. Thanks to the high level of interface compatibility, it was possible to choose from a wide range of possible automation solutions. "Such flexibility is not a matter of course," emphasises Lühr. Heiko Siebke emphasises the clear increases in productivity: "With the connected automation, we have easily doubled the capacity of the machine."

Single parts during the day, standard parts at night.

WFT's manufacturing portfolio offers optimal conditions for automation, as it produces not only single parts but also a whole range of recurring parts that are constantly needed. The company has developed its own WFT standard for this purpose. "We can simply run the end programs on the machine in accordance with this at night and at weekends," explains Siebke. During the day, single parts are produced manually on the machine according to customer orders. "This means that our employees can now devote themselves even more to the really demanding parts - that is a significant relief.

Large dimensions on a small surface area.

WFT became aware of the ACURA 65 EL at a trade fair: "The machine was presented for the first time at NORTEC 2017," recalls Siebke - "and barely a year later, it was already in our production hall." Despite its compact dimensions, the 5-axis machining centre has generous travel paths of 700 x 650 x 600 mm (X/Y/Z). The integrated rotating/swivelling table with bearings on both sides enables high-precision chipping from all sides. The connected Indumatik Light 120 automation system offers space for 24 pallets.

Automation and flexibility - no opposites.

An important factor for increasing efficiency is the possibility of main time-parallel tooling: workpieces can be stored and retrieved for the night shift without interrupting production during the day. Loading from the left-hand side of the machine also means that the machining centre door is always freely accessible. This makes it easy to switch between manual and automated operation at any time. Machining mechanic Belana Freitag also appreciates this flexibility: "We can react quickly: If something needs to be milled at short notice, we can simply interrupt production and continue seamlessly later."

Digital and personalised service is convincing.

Anyone who, like WFT, is committed to increasing efficiency must of course be able to rely on rapid assistance in the event of a fault. Looking at the HEDELIUS service, Stefan Lühr sees his investment decision confirmed time and again: "The customer service is really great. If something goes wrong, the technicians are usually there within two to three hours."

Heiko Siebke's summary is similarly positive. He is particularly impressed with the HEDELIUS service app across the board: "You simply upload a picture of the machine and get feedback within a very short time - it couldn't be better," he says enthusiastically.

So there are plenty of reasons for the WFT management duo to keep their faith in HEDELIUS. "At the moment, we are not planning to invest in another machine," says Lühr, "but when the time comes, HEDELIUS will be on the shortlist from the outset."

HEDELIUS machining centres of the customer.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.