News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

BL Lasertechnik GmbH turned a disaster into a success story. Despite the devastating fire that destroyed its production halls, the company opted for a quick restart. Thanks to the support of partners such as HEDELIUS, production was resumed and even expanded in a very short space of time.

"Never change a winning team" - this could be the headline for the collaboration between HEDELIUS Maschinenfabrik and automation specialist BMO at the Dutch manufacturing company Edumar Metaalbewerking. On the way to even more flexible unmanned production, the choice has now been made for the second time in favour of a joint solution from the two manufacturers.

The Swiss company Meag AG invested in two identical HEDELIUS 5-axis machining centres from the ACURA-85 series with the aim of being able to supply customers even more efficiently and quickly in the future.

WFT Werkzeug- und Frästechnik GmbH** specialises in the precise production of pre-series and series tools for the plastics processing industry. The company's example impressively demonstrates what can be achieved with the right automation solution - and why employees also benefit from it.

Anyone visiting WuM Werkzeug- und Maschinenbau GmbH in Mühlhausen, Thuringia, will get an impression of the end products that are manufactured using their tools from the entrance lobby. WuM machines high-precision stamping tools for the automotive industry on a TILTENTA 7, an ACURA 85 and a FORTE 11.

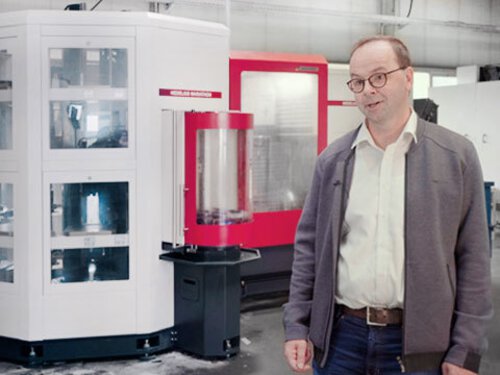

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.