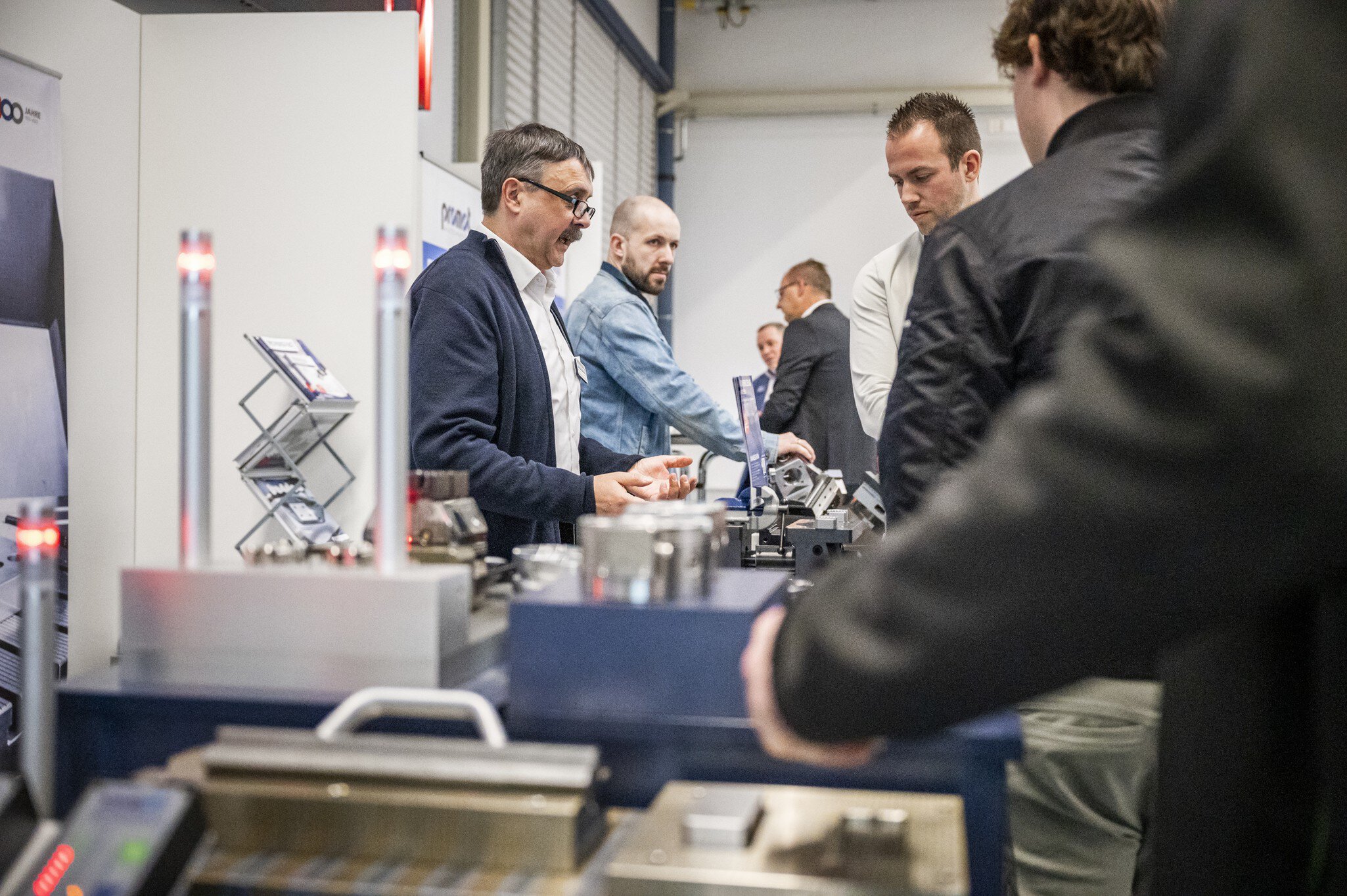

Speaker: Frank Biemans

Multi-batch automation means that your autonomy is no longer dependent on the number of units. Preferably, the autonomy is longer than a weekend (>62 hours) but at least longer than the time between two daily shifts (>16 hours). In multi-batch mode, BMO robots produce several small series one after the other without supervision. For this purpose, several products are set during the day shift, which are then produced unmanned at night and at weekends. The autonomy corresponds with the production time of all set small series together.