From a single source.

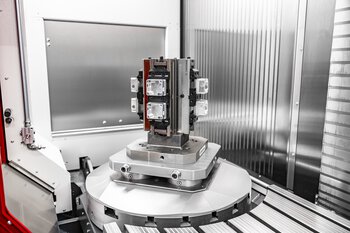

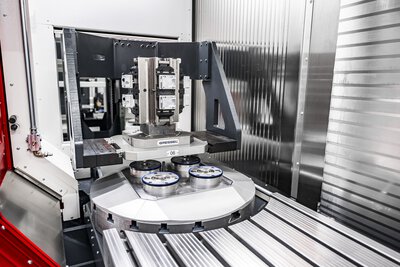

Swivelling spindle technology meets automation.

The demand for efficient automation solutions is constantly growing - especially for the versatile machining centres in the popular TILTENTA series. With decades of experience in the development of compact, ergonomic machining centres and powerful automation solutions, we are pleased to present our latest innovation: the TILTENTA 7-2000 NEO in combination with the MARATHON SR415. A combination that promises maximum productivity with minimum space requirements.

Maximised machining output.

Through mixed production.

In the shift on

Day

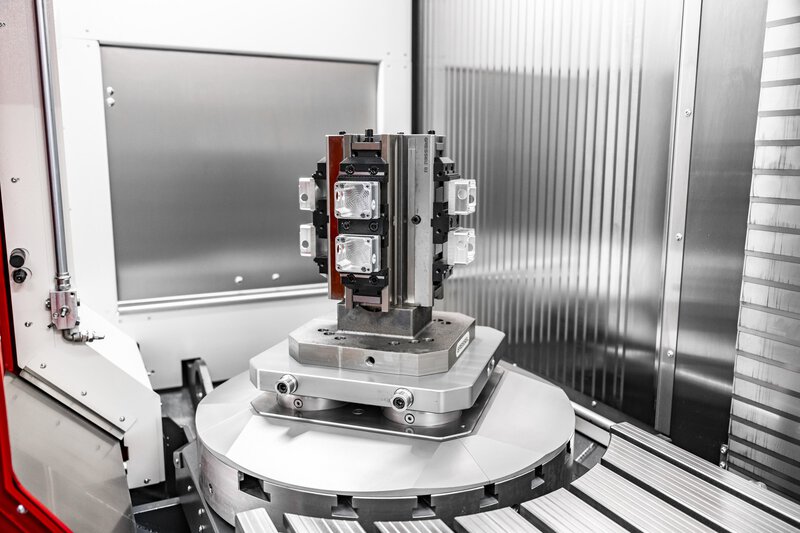

Highest precision for demanding components

During the day shift, demanding production tasks are mastered: complex geometries, long or heavy components and high-precision machining. The TILTENTA 7-2000 NEO offers the perfect solution for these challenges with its flexible swivelling spindle and generous travel paths.

High-precision 5-axis machining for complex single parts

Machining of long and heavy workpieces with a large work area

Combined 5-axis and long part machining for maximum flexibility

Efficient machining of prototypes and customised products

at the weekend AND IN THE

NIGHT

Automated series production

After work, production continues: The TILTENTA 7-2000 NEO produces small and medium-sized series in unmanned operation thanks to its connection to the MARATHON SR415 pallet automation system. This optimises machine runtimes and reduces unit costs - around the clock.

Automated production of small and medium series

Maximum spindle running time thanks to unmanned night shifts

Reduction of unit costs through continuous production

Efficient utilisation of machine capacity even at weekends

The duo for more efficiency.

Discover the advantages and functions of the combination.

All the facts at a glance.

Discover the performance parameters of the CNC solution.

Experience live.

Check out the performance for yourself: In our HEDELIUS technology centre, you can experience a total of six machining centres with connected automation live. Arrange a personal demonstration appointment with our technical experts.

More news.

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!