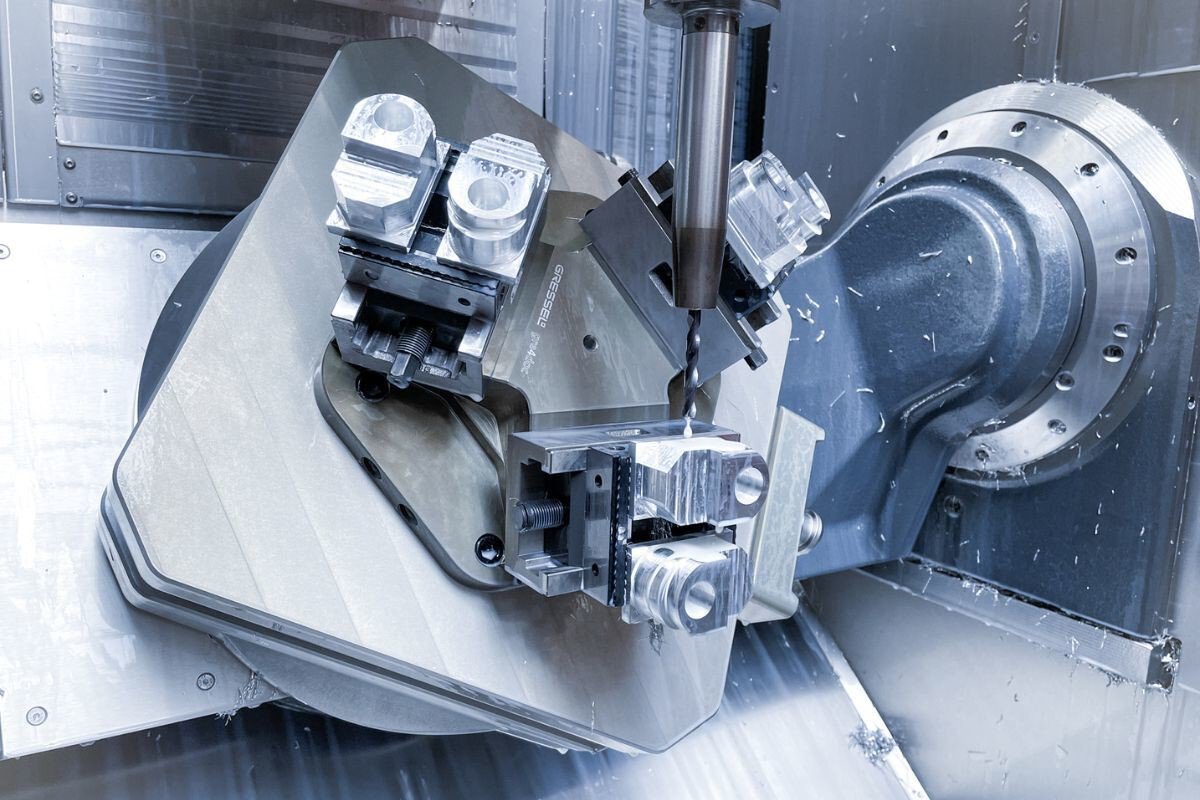

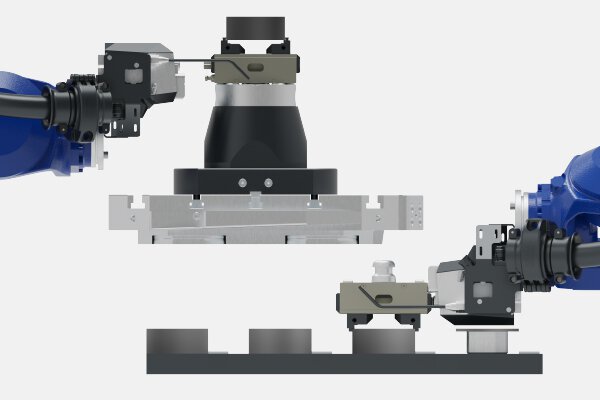

Full power for 5 axes

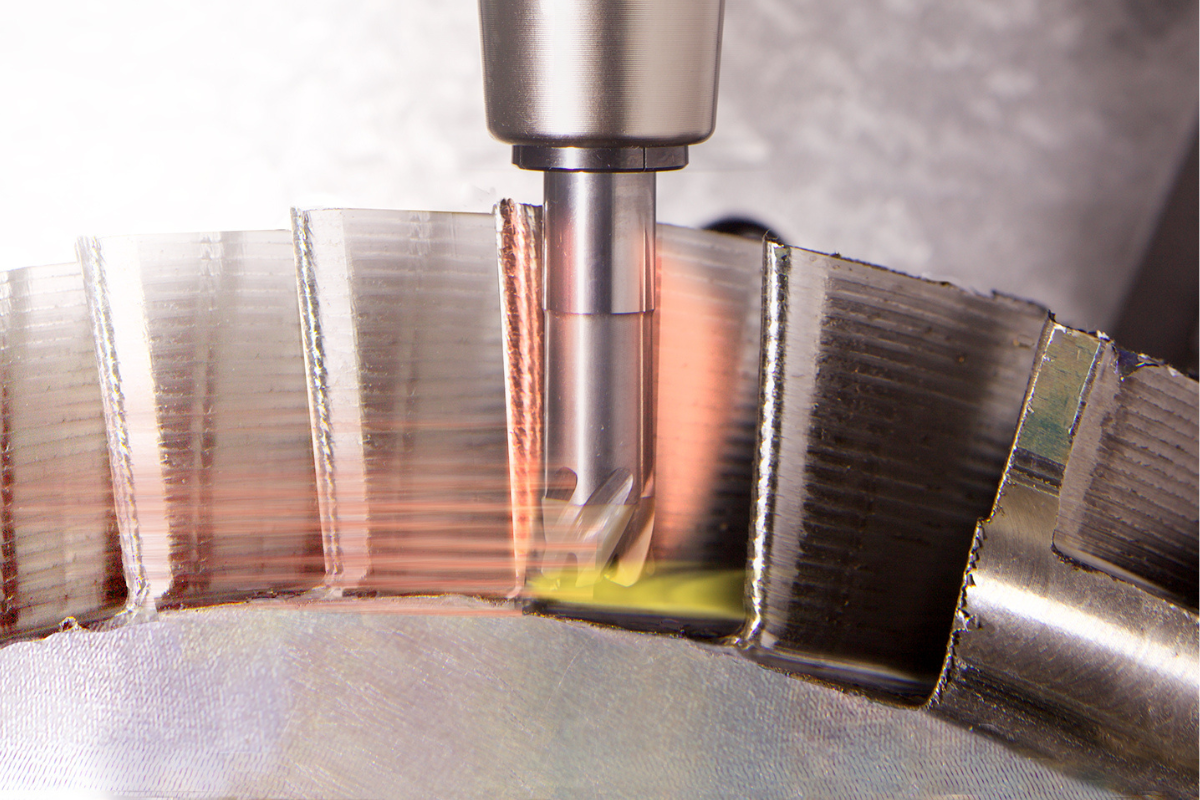

The chuck specialist Albrecht has developed the Slim5 precision chuck with mechanical clamping gear and a large clamping range for 5-axis applications with the highest demands. With a tensile force of more than 3 tonnes, which is achieved by the globally unique 1:16 gear ratio, the new chuck enables a significantly higher holding force. The perfect combination of interference contour, holding torque, vibration damping and concentricity ensures high Chipping output and process reliability.

www.albrecht-praezision.de