WVG Alu tec GmbH | TILTENTA 7-3200

Field of application: Foundry | Company headquarters: Bad Arolsen, Germany | Employees: 50

There is hardly anyone in Germany who has not come into contact with products from WVG alu-tec GmbH at some point. Most of them, of course, without realising it. Manufacturers of cast aluminium from Bad Arolsen can be found in furniture as well as in Deutsche Bahn trains, restaurant and beer garden billboards or in the illuminated advertising of the pay-TV channel Sky. Yes, WVG alu-tec is even represented in medical technology!

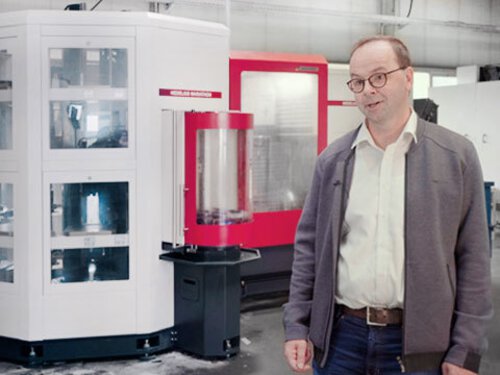

But first things first: The company WVG alu-tec GmbH was founded in 2001. Previously, the aluminium casting division was part of WVG Industrie- und Schalttechnik, based in Lohfelden near Kassel. After several relocations, the company has been closed in Bad Arolsen since 2016. Managing director Armin Gruhs has been with the company from the very beginning.

HEDELIUS: A trustworthy partner.

Over 10 years ago, the entrepreneur decided to invest in CNC machines for manufacturing the moulds and in machines for post-processing the castings. He found what he was looking for at HEDELIUS.

"We simply want to keep going, to always be one step ahead," says Armin Gruhs. And that is only possible with partners with whom there is the highest level of trust. "We've known HEDELIUS for many years, we're like family. And where do you trust each other more than within a family?"

No downtime thanks to the work area partition.

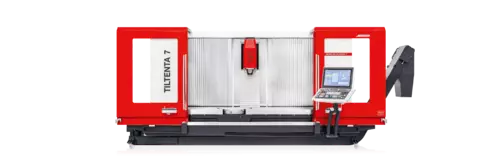

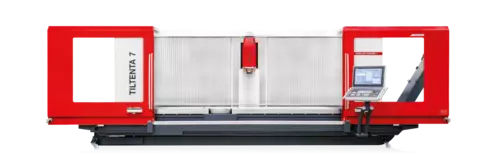

This is why Gruhs is also proud of the "latest achievement", as he says: the TILTENTA 7-3200 5-axis machining centre with swivelling spindle and two integrated NC rotary tables.

"The components are getting bigger and bigger. And here we can make full use of the 3.20 metre machining area. We can also machine two components at the same time, always alternating between the two machining sections of the TILTENTA, so that we have no machine downtimes." This is made possible by the use of a work area partition. This separates the large machining area into two smaller work areas, which can now be used for machining on one side and set-up on the other.

The quality and surface finish of the components are always impressive. But the alu-tec employees are already familiar with this from the three other HEDELIUS machines that are open on the almost 25,000 square metre site

Make components more energy-efficient.

50 people work at the factory. And their future does not depend solely on the quality and innovation of their products. More than ever, it's also about energy. Costs, of course - but also climate friendliness. Not an easy topic. But that's where it fits again: Armin Gruhs' thoughts and HEDELIUS' ideas. Because with the new TILTENTA, components can be manufactured faster and therefore more energy-efficiently and with lower CO-2 emissions.

That is future-orientated. And that brings us back to the family concept: two of Armin Gruhs' children have already joined the company. They also bring new, fresh ideas with them. Just like HEDELIUS. The TILTENTA 7 is probably not the last generation of machines to be delivered from Meppen to Bad Arolsen ...

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups on the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.