European Transonic Windtunnel GmbH | TILTENTA 7-3200

Field of application: Air and space technology | Company headquarters: Cologne, Germany | Employees: 34

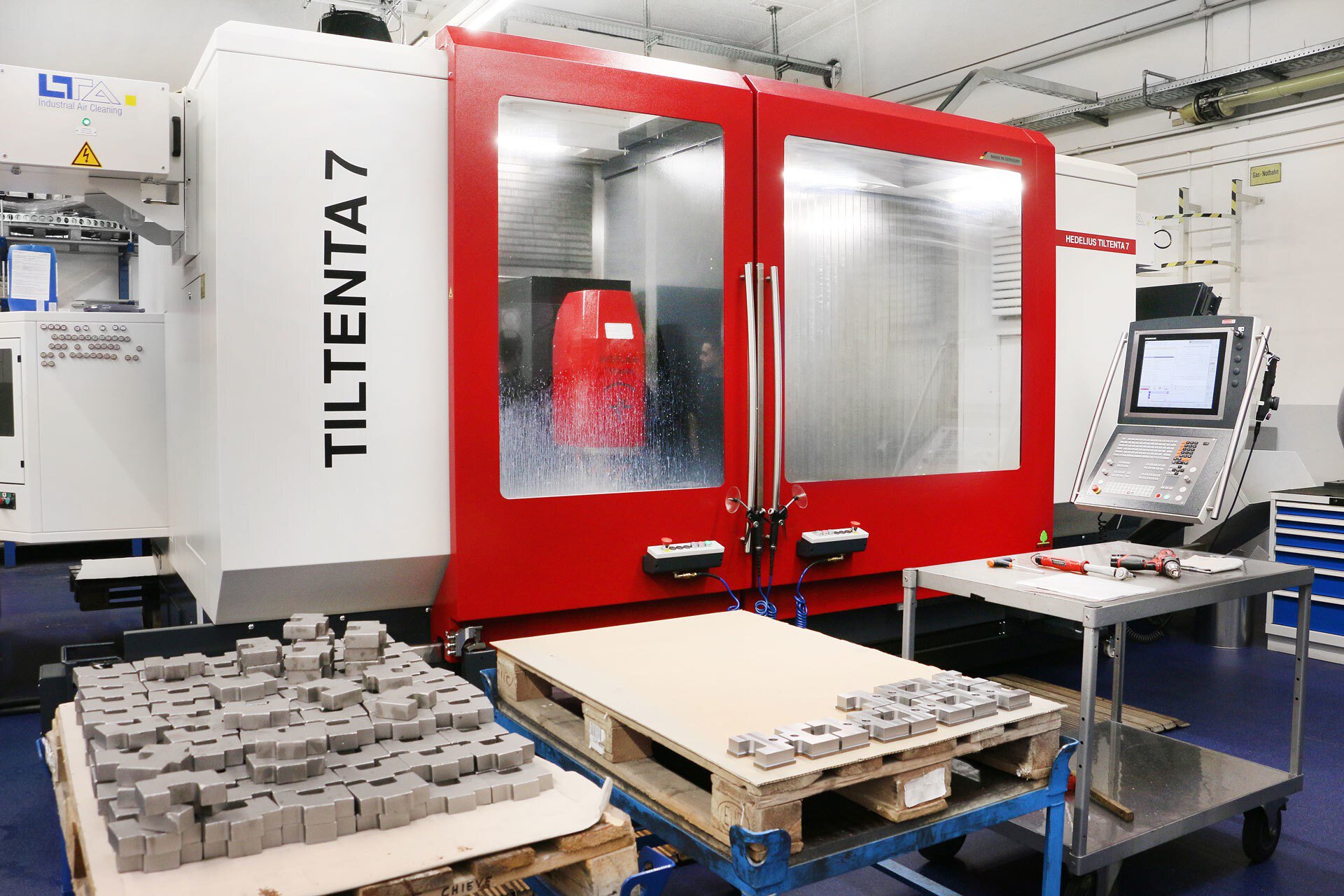

The wind tunnel system at European Transonic Windtunnel GmbH is currently being modernised and its range of capabilities expanded. This also includes the modernisation of the workshop, for which a Tiltenta 6-2300 from HEDELIUS was purchased. This means that full and half models of aircraft with a length of up to 2.30 metres can now be machined in a single set-up.

The European Transonic Windtunnel is located very close to Cologne/Bonn Airport. Its operating company, ETW GmbH, is a non-profit organisation that operates an extraordinary wind tunnel for research and development purposes. This European joint project was launched in 1988 by Germany, the Netherlands, France and the UK and today employs 34 people. In the world's most modern wind tunnel facility, research is carried out for civil aviation under extreme conditions and real flight conditions are simulated on a model scale. The models are used to test prototypes, product improvements and innovative aircraft technologies for flight characteristics, economic efficiency and noise reduction. The models have to withstand pressures of up to 4.5 bar and temperatures as low as -163° C. They are supplied by customers from the international aviation industry and meet extremely high requirements and standards. If something needs to be adjusted on a model, it must be processed quickly and very precisely. A TILTENTA 6-2300 5-axis swivelling spindle machining centre from HEDELIUS was purchased for this purpose.

Accuracy and flexibility required.

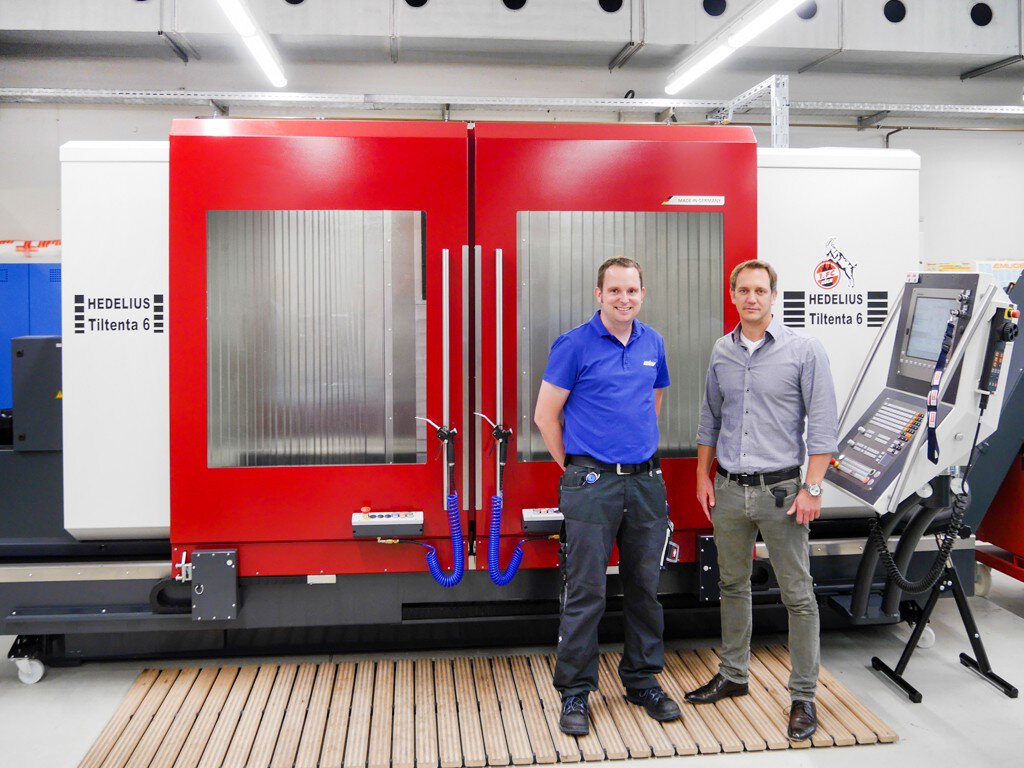

"We need accuracy and flexibility, we have to be able to react to everything. If we were to send the models back to the customer and have them reworked there, we would lose at least two valuable days, which neither our customers nor we can afford," says André Kasper, describing the situation and explaining the purchase of the HEDELIUS machine. As Project Manager at ETW, the industrial engineer is responsible for the expansion and renewal of the system. Dr Peter Guntermann, Manager Operations & Administration, adds: "It is important that we are flexible and do not have to give away critical parts of the models for processing."

Machine 2.30 metre long models in just one clamping operation.

The assembly and test phase of a model usually takes two to three weeks, after a test plan has been drawn up with the customer. In preparation, the model, consisting of many single parts, is assembled. The sensors and measuring instruments are inserted - there can be around 280 holes in a wing - before the model is finally mounted on a handle on the model holder of the test facility. The scales, the centrepiece of the measuring system, are located between the model and the handle. It can happen that the models need to be adjusted to the system or that shape changes are required during the tests. This requires very precise machining at certain points. "In the past, we had to dismantle the models again if we wanted to modify something; with the HEDELIUS, we can now machine the model precisely in a single clamping operation with little effort," explains André Kasper. "The TILTENTA 6's X travel path of 2300 mm was therefore very important to us." This is because the models can have a length of 2.30 metres and a span of up to 1.60 metres.

Tough steels for temperatures down to minus 196 °C.

The wind tunnel must build up extreme temperatures and pressures in order to create realistic flight conditions. In addition, the air must be extremely dry. Portholes for cameras and lighting systems are embedded in the wind tunnel so that the model can be observed during the test and its deformations can be measured. 3000 tonnes of liquid nitrogen are available to keep the channel closed to temperatures as low as -163 °C during the test phase. Only at such ultra-low temperatures and pressures of up to 4.5 bar can conditions be created that correspond with real flight conditions on a model scale. This has to do with the Reynolds number, a key figure from fluid mechanics. This can be as high as 80 million for large aircraft, while other wind tunnels do not achieve such values. André Kasper explains: "Of course, such low temperatures do not prevail in real flight operations, but in order to achieve real flow behaviour, the temperature must be so low. In this way, the behaviour from the wind tunnel can be transferred to reality. This gives us the accuracy we need." To ensure that the models can withstand these extreme test conditions, special, low-temperature steels are used. "We mainly work with maraging steel, Marval 18 and Alloy A 286," explains Karsten Horn, user at ETW. These are particularly tensile materials that do not become brittle at very cold temperatures. A machine capable of chipping these materials was therefore also required. The powerful Celox spindle of the TILTENTA 6-2300, with 14,000 rpm and 29.00 kW output, meets these challenges.

The service is crucial.

In addition to aircraft models, Spare parts for the wind tunnel and very small electrical engineering components are also manufactured on the HEDELIUS. "Tooling times generally play a subordinate role for us. We programme at the machine and machining usually only takes a few minutes," says Karsten Horn, describing the situation in the workshop. At ETW, the basic equipment of the machine is sufficient, but other things were much more important when making the purchase. "The service was very important to us, the machine has to run when we need it," explains Project Manager Kasper. "We therefore gathered information from other HEDELIUS customers beforehand and received positive feedback there. We can now confirm this." The design of the machining centre was also impressive. Thanks to the side loading flaps, the model bodies can sometimes be longer and still be machined in a single clamping operation. Another detail of the TILTENTA 6-2300 that also impressed the customer was the direct access to the workpiece. "Of all the machines we looked at, we had the best access to the workpiece here," explains user Horn. This is partly due to the low table height of approx. 800 mm and the special TILTENTA design. It must also be possible to work professionally with a new machining centre. This is why European Transonic Windtunnel GmbH opted for basic and advanced training courses from HEDELIUS. "I've never had such good training before," says user Karsten Horn, visibly satisfied with the recently attended advanced swivelling course.

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups on the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

BL Lasertechnik GmbH turned a disaster into a success story. Despite the devastating fire that destroyed its production halls, the company opted for a quick restart. Thanks to the support of partners such as HEDELIUS, production was resumed and even expanded in a very short space of time.