News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

With the new Infinity series, it is now possible to realise even more unmanned processing time with our machines thanks to the enlarged pallet and workpiece storage space. The system also meets the desire of many users to link several machining centres in a series as a flexible production system.

In order to meet the increasing demands of our customers, we have developed our first automation system based on a 6-axis robot, the MARATHON RZ multi-pallet magazine system.

This is why HEDELIUS is now opening a version of the STANDBY MAGAZIN with 264 tool pockets. In total, our customers will then have access to up to 329 tools on a TILTENTA 11 swivelling spindle machining centre and up to 344 tools on an ACURA 85 5-axis machining centre, for example!

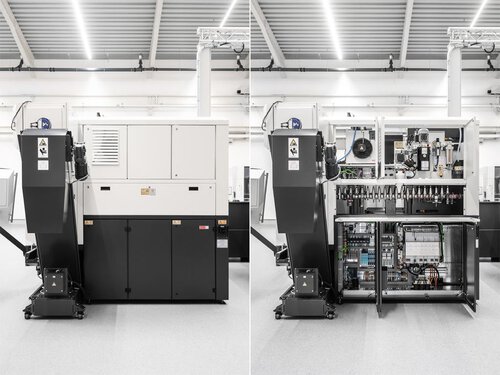

With the ACURA 65 MAGNUM and the MARATHON pallet magazine, we have a real ace in our programme for the production of small series. A 90-fold tool magazine, 6 pallets 400 x 400 mm and 250 kg clamping weight ensure your productive edge. Experience it live now at the HEDELIUS demonstration centre.

Lang Technik GmbH from Holzmaden delivered its ROBOTREX 96 automation solution to Meppen just in time for the in-house exhibition. The automation cell consists of a FANUC 6-axis robot with a payload capacity of 50 kg and two automation trolleys, tooling with a total of 46 vices.

Today, a machining centre must not only work quickly, precisely and reliably, but also look good. HEDELIUS therefore offers a paint finish for the work area doors of all machines according to your colour requirements.

Whether workpiece set-up, tool set-up, programming or maintenance - the focus is always on convenience, safety and productivity in your production. A clear operating and maintenance concept with good accessibility to all working ranges and optimally arranged control elements make daily work easier.

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.