08 November 2023

NOW NEW: BMO INFINITY.

Flexibly expandable automation solution for pallets and workpieces.

Expansion of hybrid automation into a flexible production system for even more flexibility in the mixed production of single parts and series.

BMO Automation from Neederwert, Netherlands, has been an important automation partner of HEDELIUS for many years. BMO hybrid automation of the Platinum or Titanium type is now in use on over 50 HEDELIUS 5-axis machining centres.

With the new Infinity series, it is now possible to realise even more unmanned processing time with our machines thanks to the increased pallet and workpiece storage space.

The system also meets the wishes of many users to link several machining centres from a series as a flexible production system.

Highlights of the BMO Infinity.

Configurable shelving system.

The centrepiece of the system is a freely configurable rack for holding pallets and beams with a grid for storing workpieces for direct loading. The integrated automatic height measurement ensures optimum utilisation of the rack storage.

Flexible manufacturing system.

The number of shelves can be freely configured in different widths. As an option, the robot can be mounted on a floor trolley. This creates a flexible production system for multi-machine interlinking.

Variable gripping systems.

The trays with the workpieces to be processed are placed directly in front of the respective machining centre for processing. Servo-controlled, automatically adjustable grippers allow several machining centres to be loaded effectively, even with short cycle times.

Optional use of pallets.

Workpiece pallets are used to close heavy workpieces or individual clamping devices.

Examples of the BMO Infinity's equipment.

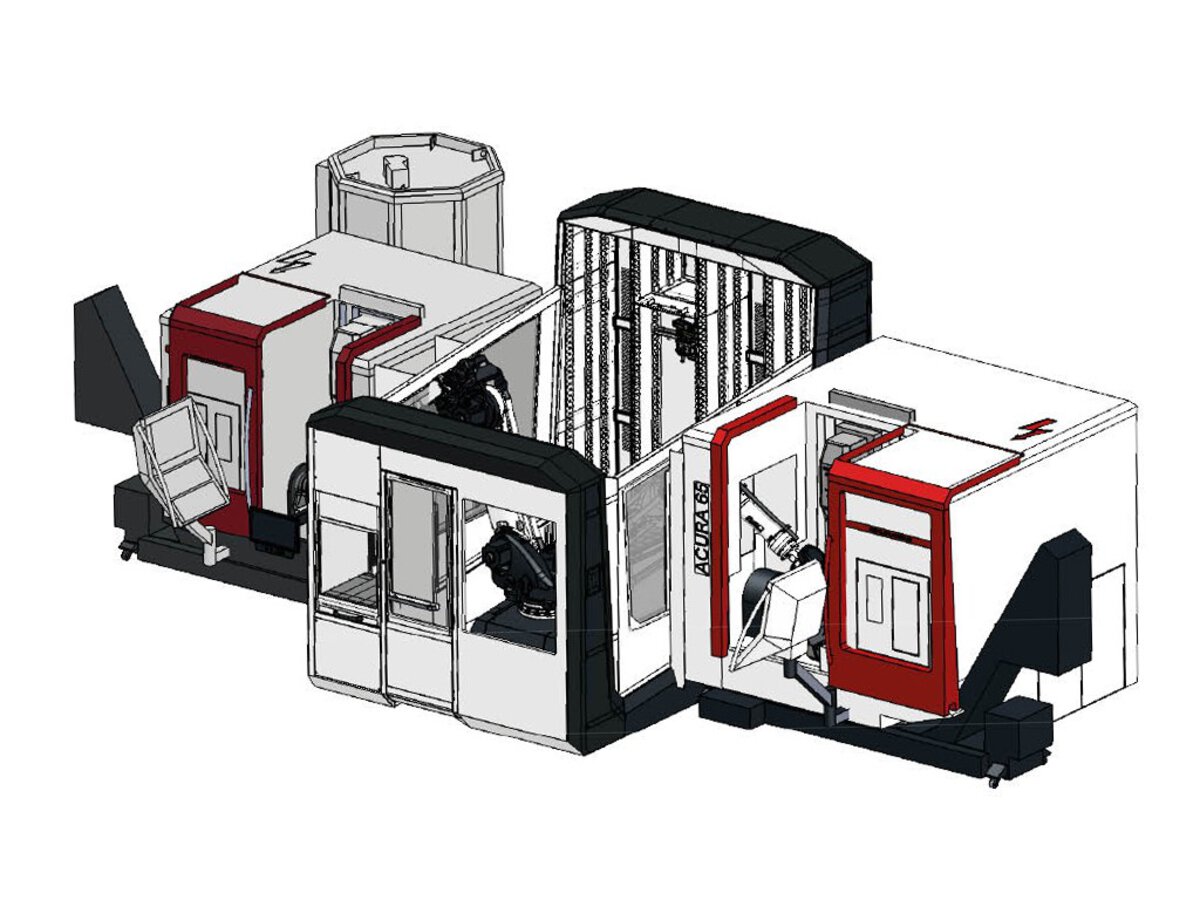

Equipment example 1

BMO Infinity as a Twinner version for loading an ACURA 50 and an ACURA 65.

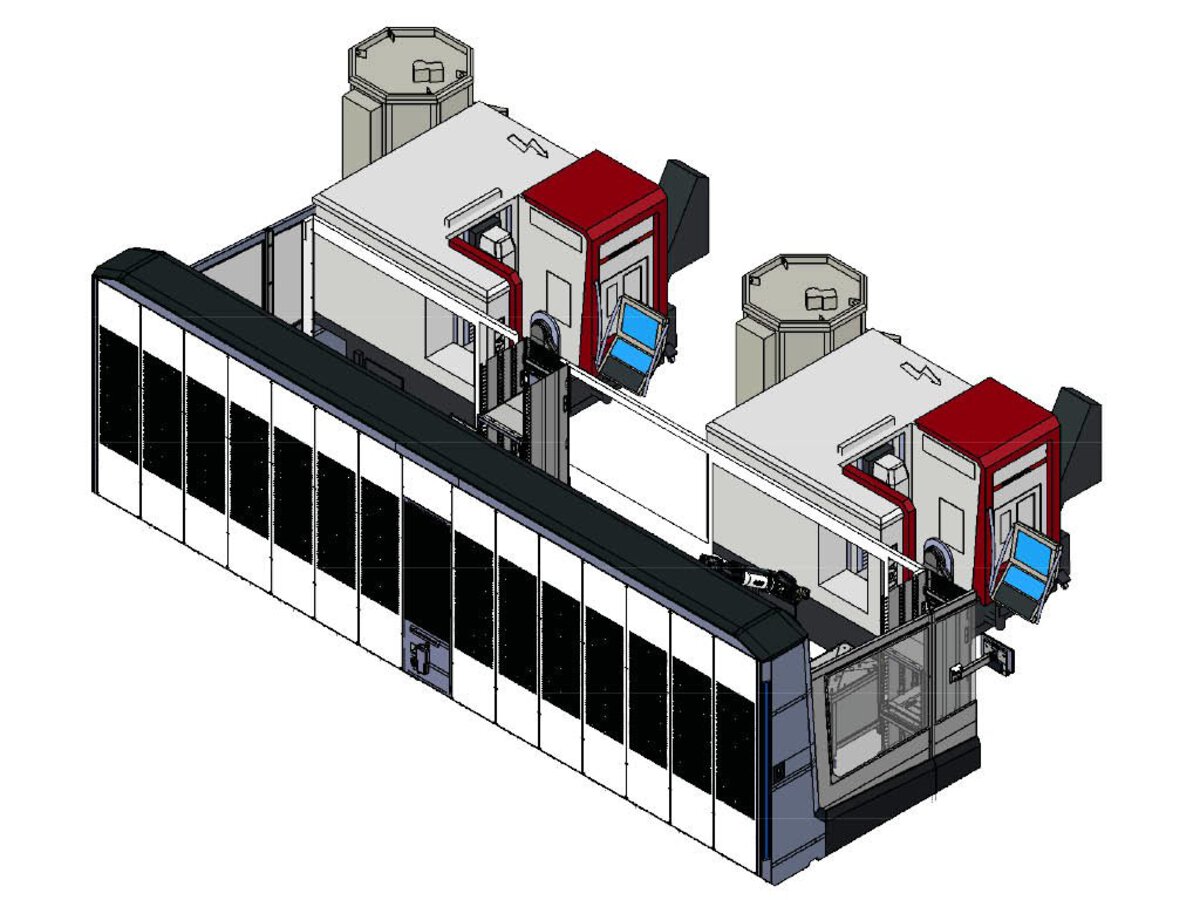

Equipment example 2

BMO Infinity as a flexible production system with floor trolley for loading two ACURA 65s.

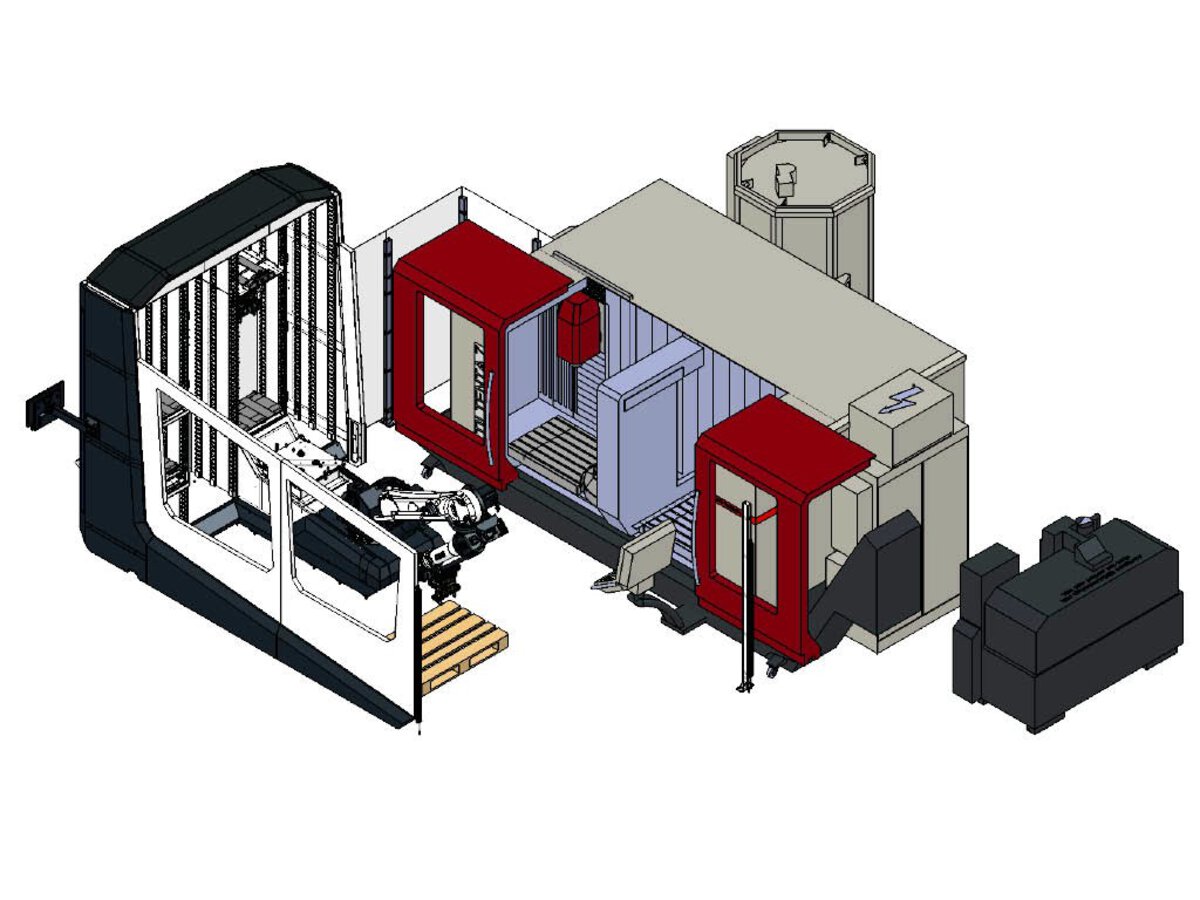

Equipment example 3

BMO Infinity for loading a TILTENTA 7 with additional Euro pallet module to expand capacity.

Request for the BMO Infinity.

Are you interested in the BMO Infinity and would like more information or a customised quote? Our team will be happy to answer your questions and help you close your next step in machining technology.

Please complete the form and we will contact you promptly to discuss your requirements and provide you with all the information you need.

This form requires your consent to third-party cookies. Privacy settings

Further informationMore news.

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!