24 January 2022

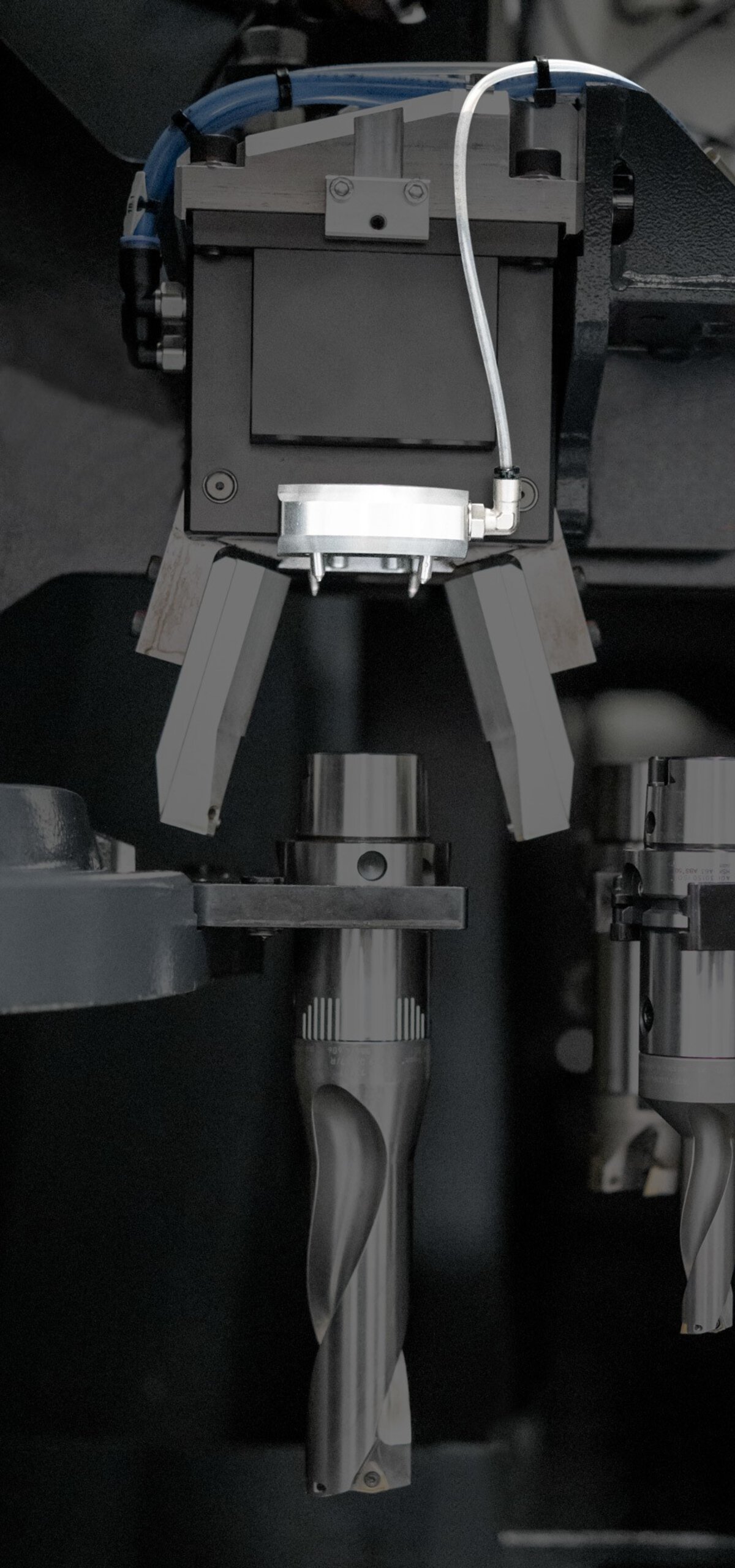

NEW: Integrated cone release function in the tool magazine.

Additional blow-off function with flow-optimised nozzle.

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. In volume machining of aluminium, however, it can happen that chips get onto the steep-angle taper or the face of a tool, e.g. due to the movement during tool change or dripping coolant. In automated production in particular, this can reduce process stability and lead to rejects. For this reason, HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.

More news.

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!