ACURA series: small dimensions, maximum precision.

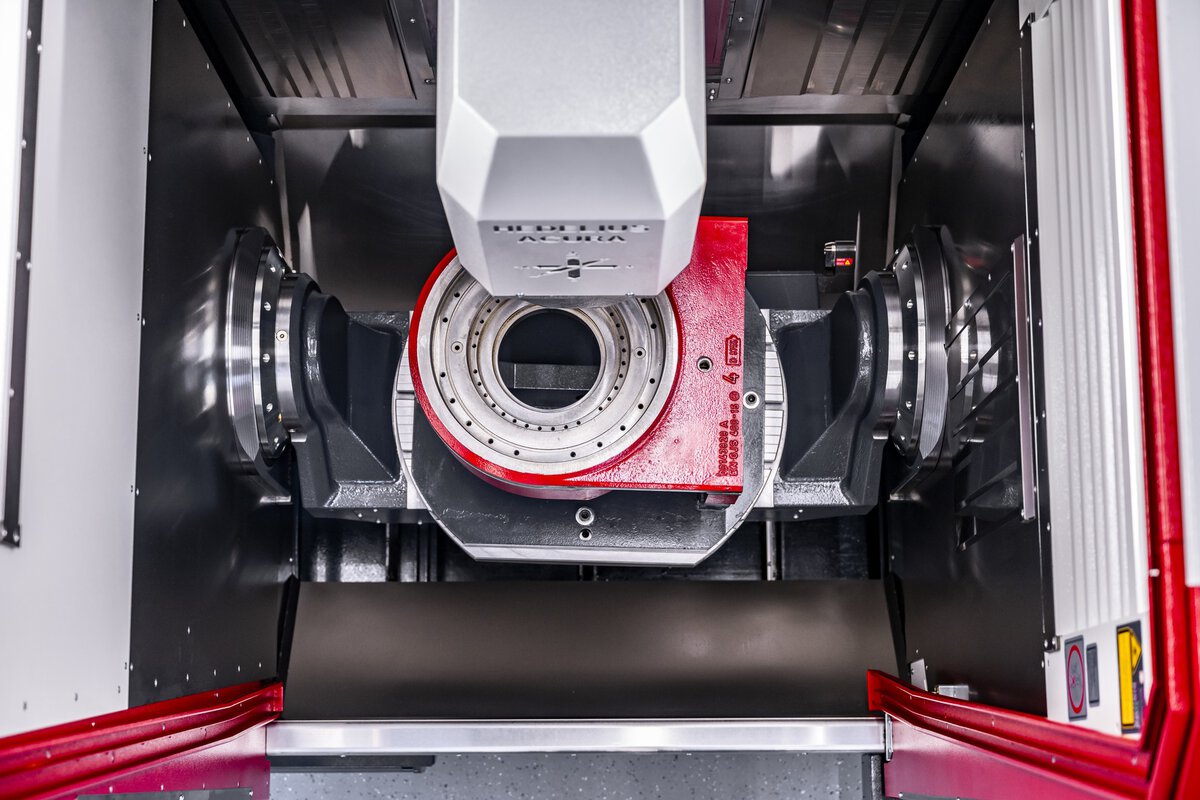

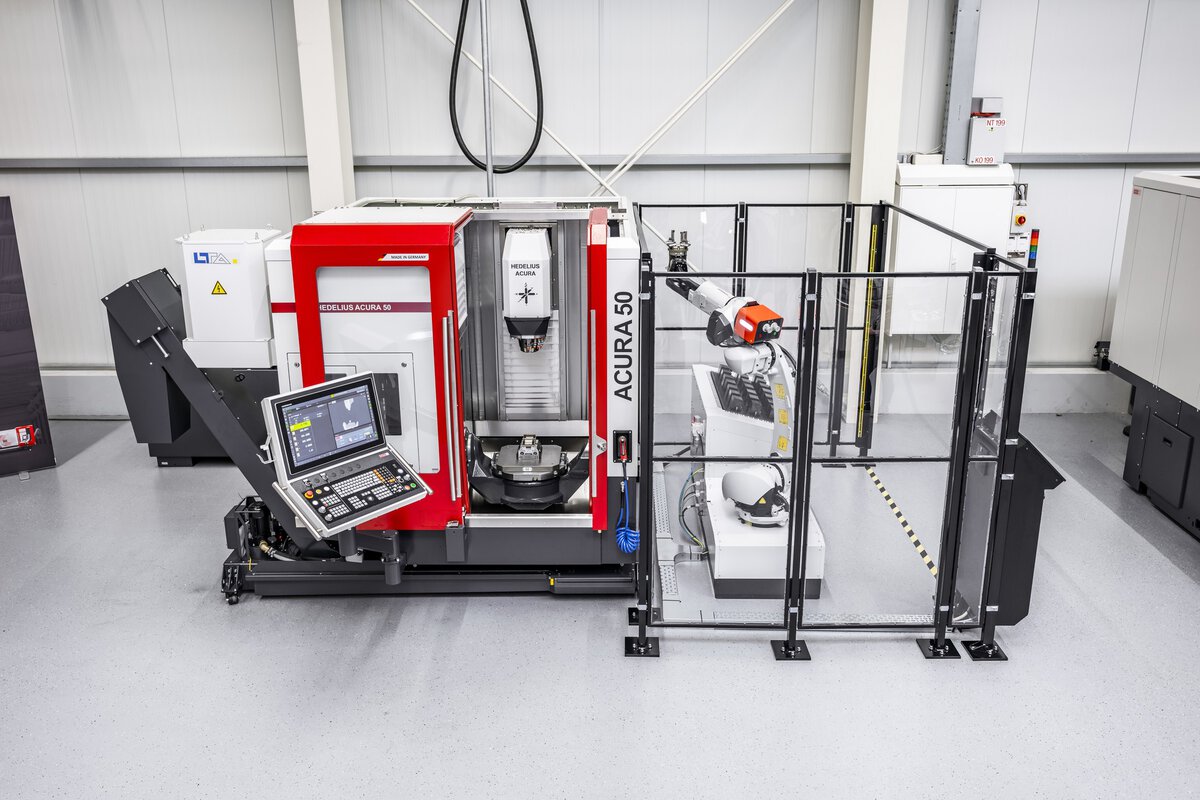

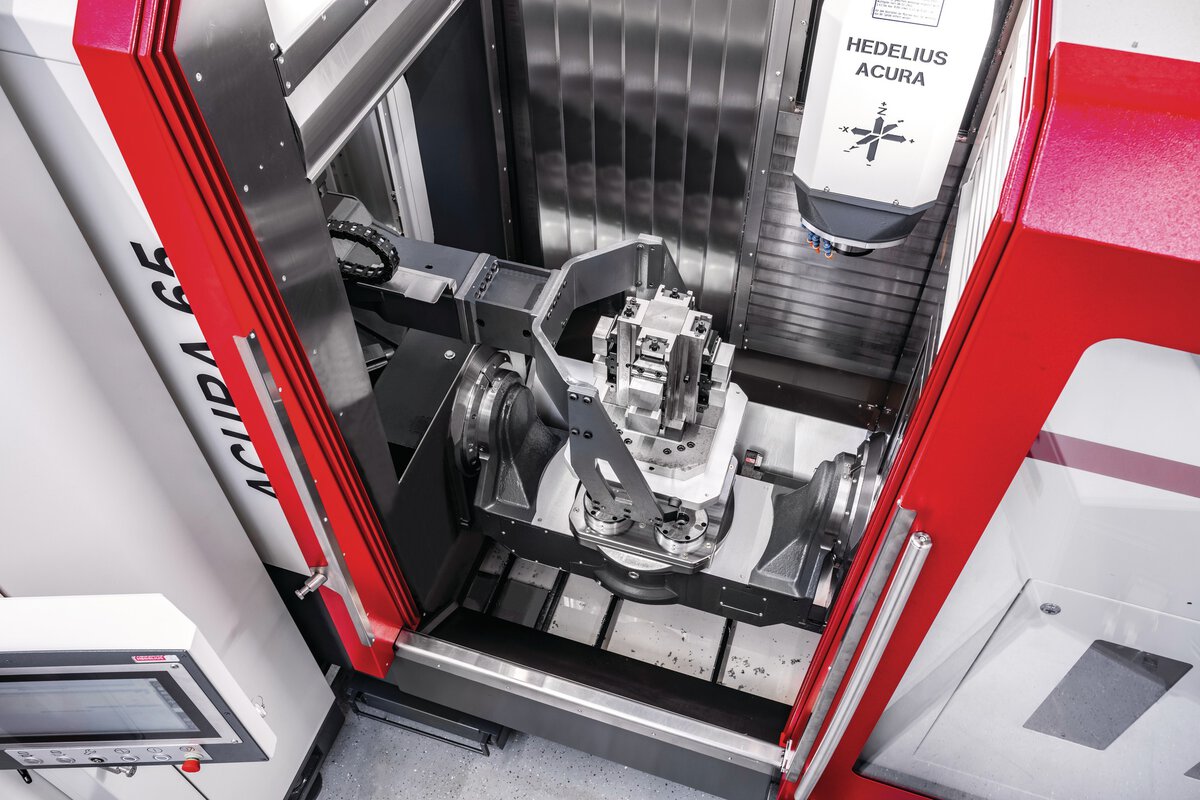

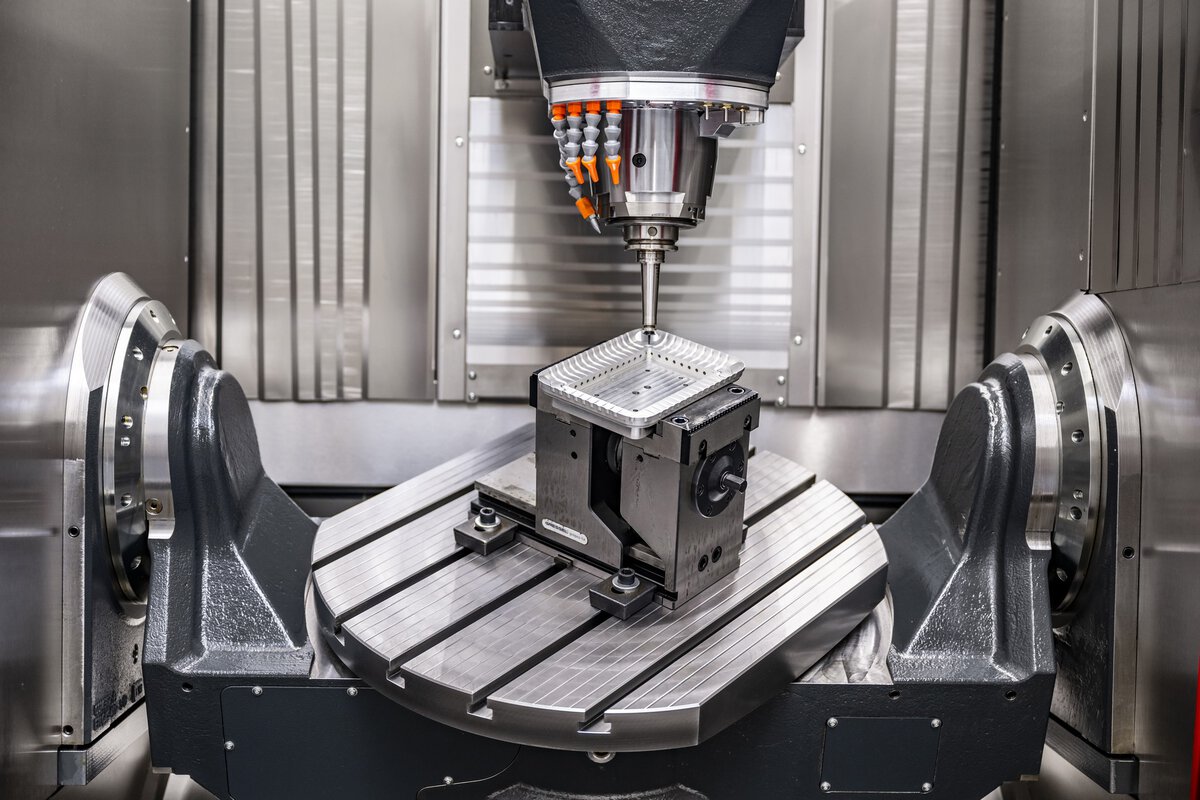

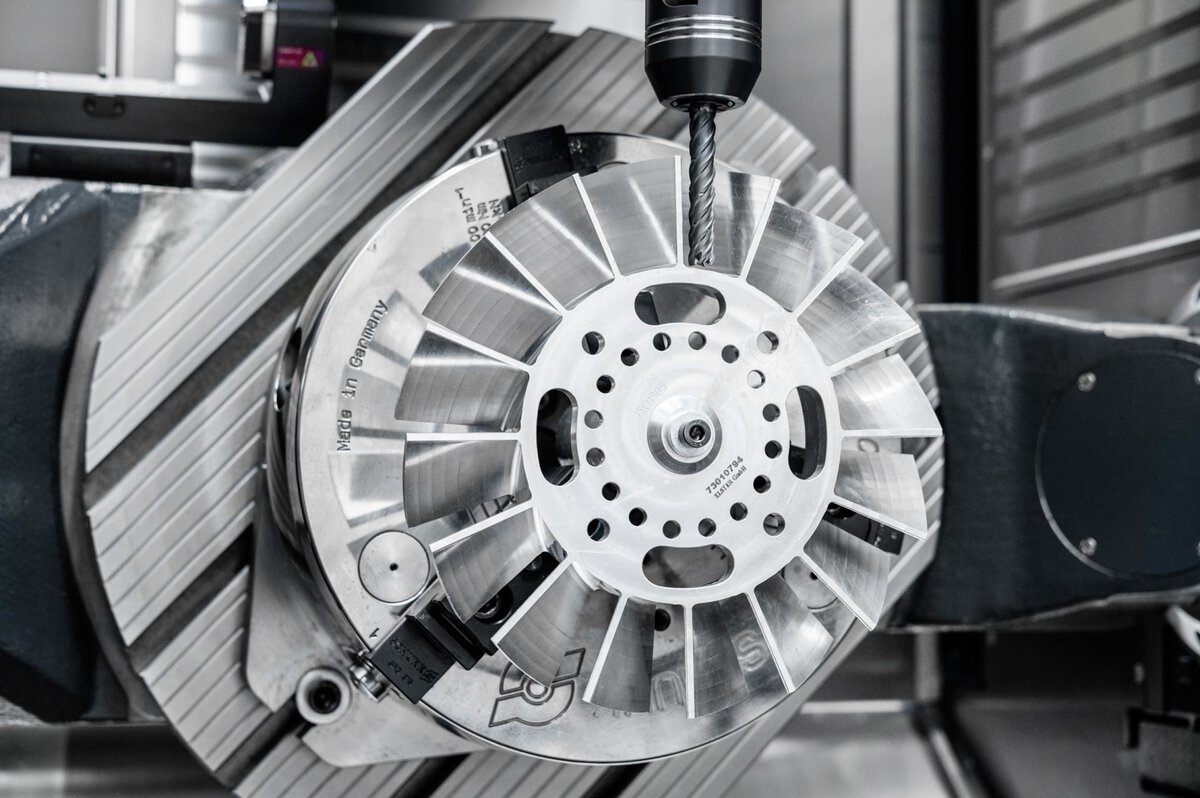

The ACURA series was developed to enable complex workpieces to be machined not only with high precision, but also reliably and quickly in 5 axes. The modern travelling column concept is just as impressive in high-productivity parts production as it is in performance machining. The type of ACURA with a constant vertical axis eliminates the disadvantages of many conventional machining centres and ensures better accuracy and higher cutting performance. Thanks to its small dimensions, an ACURA can also be integrated into almost any production facility. A large sliding door and the low machine bed height provide perfect access to the rotating/swivelling table of the 5-axis machining centre. This makes it easier to set up and control the machining process for single parts and small series production. The stainless steel cover and vertical cladding in the work area ensure exemplary chip fall and reduce the amount of cleaning required. Crane loading is possible without restriction.

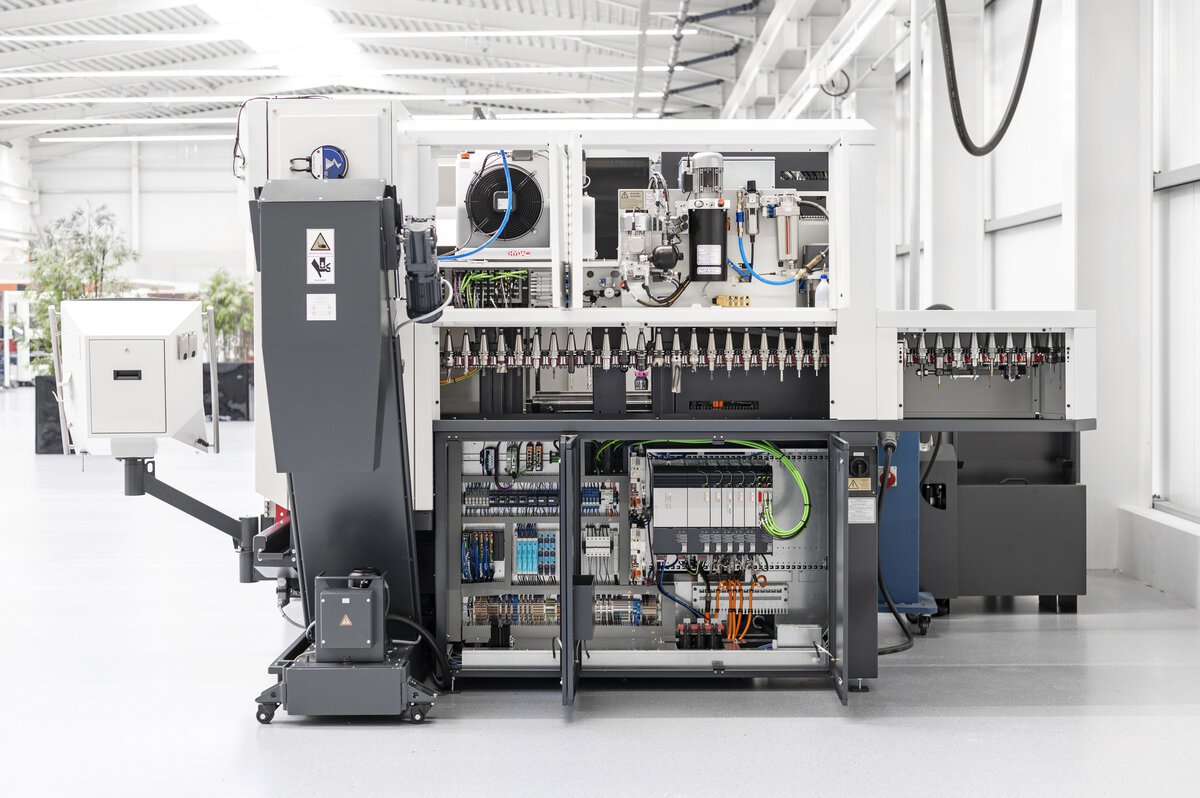

Make it more profitable.

automation for batch

size 1 to 500.

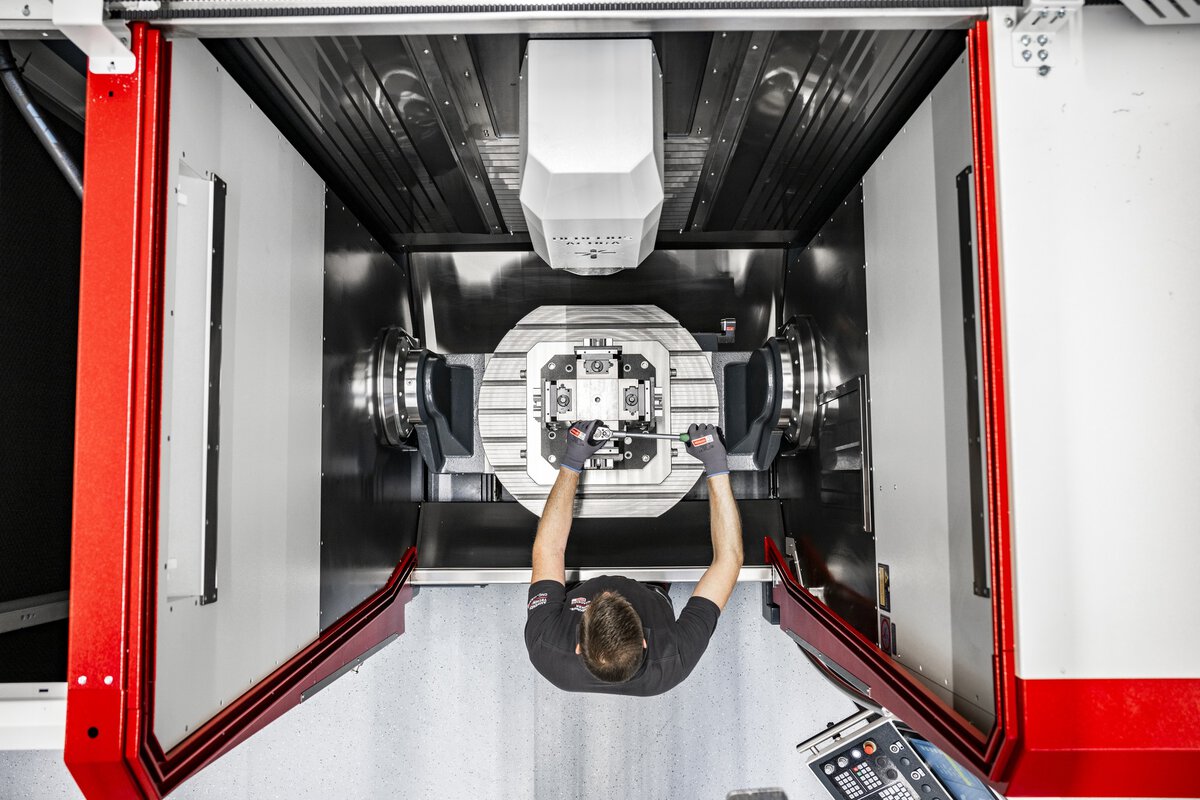

Thanks to lateral automation, the work area remains fully

available for set-up and control work as well as single

part production during the day shift. Crane loading of

the ACURA is also possible without restrictions.

ACURA Series.

5-axis machining centres with rotating/swivelling table mounted on bearings on both sides.

Visit us at the

TECHNOLOGY CENTRE.

Experience the top performance of our CNC technology up close: We cordially invite you to visit our technology centre in Meppen and see the precision of our machining centres for yourself.

Reference reports from HEDELIUS customers.

Over 3000 well-known customers from all over Europe put their trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups on the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

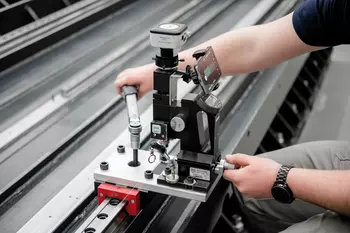

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.