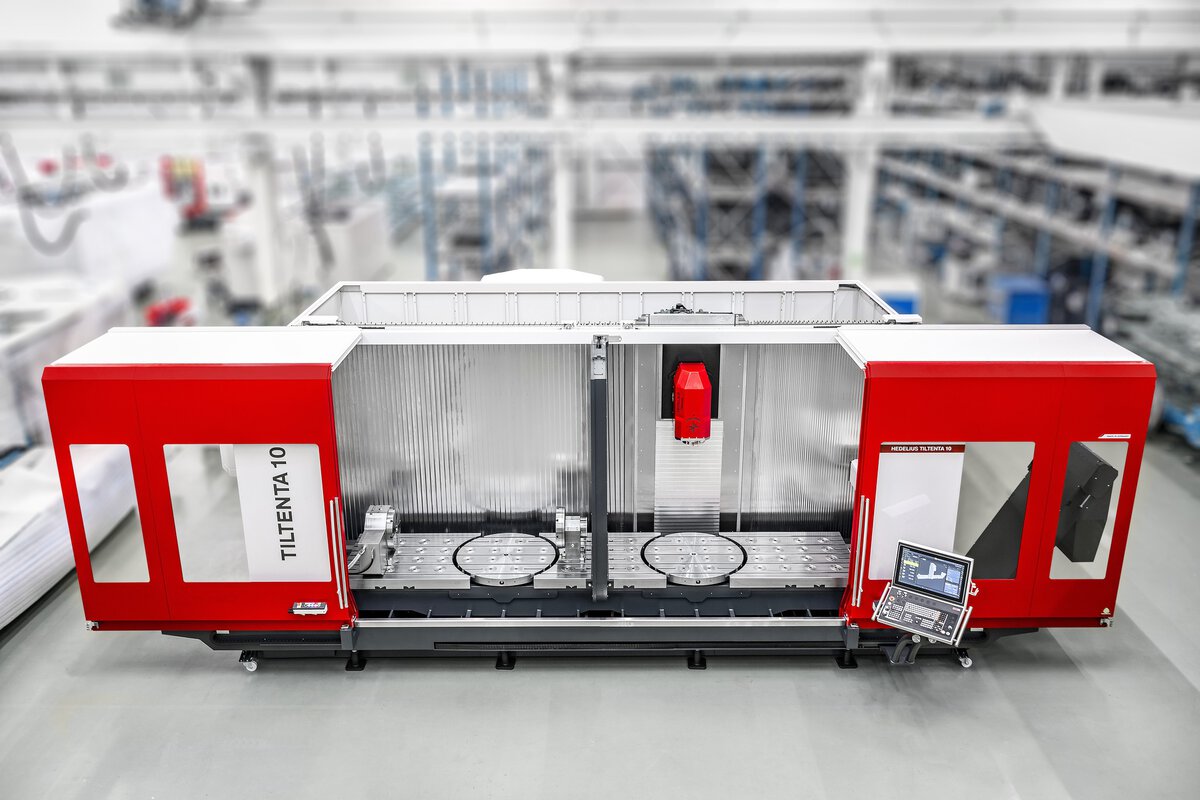

Tooling optimisation.

For maximised chip runtime.

Optimising tooling times is crucial to closing efficiency and competitiveness in chipping. By using standardised processes and set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can reduce unit costs, save resources and increase flexibility. This not only enables improved machine and plant utilisation, but also the efficient production of small batch sizes with consistently high quality. HEDELIUS supports manufacturing companies with a wide range of solutions and innovative technology to help them close these gaps.

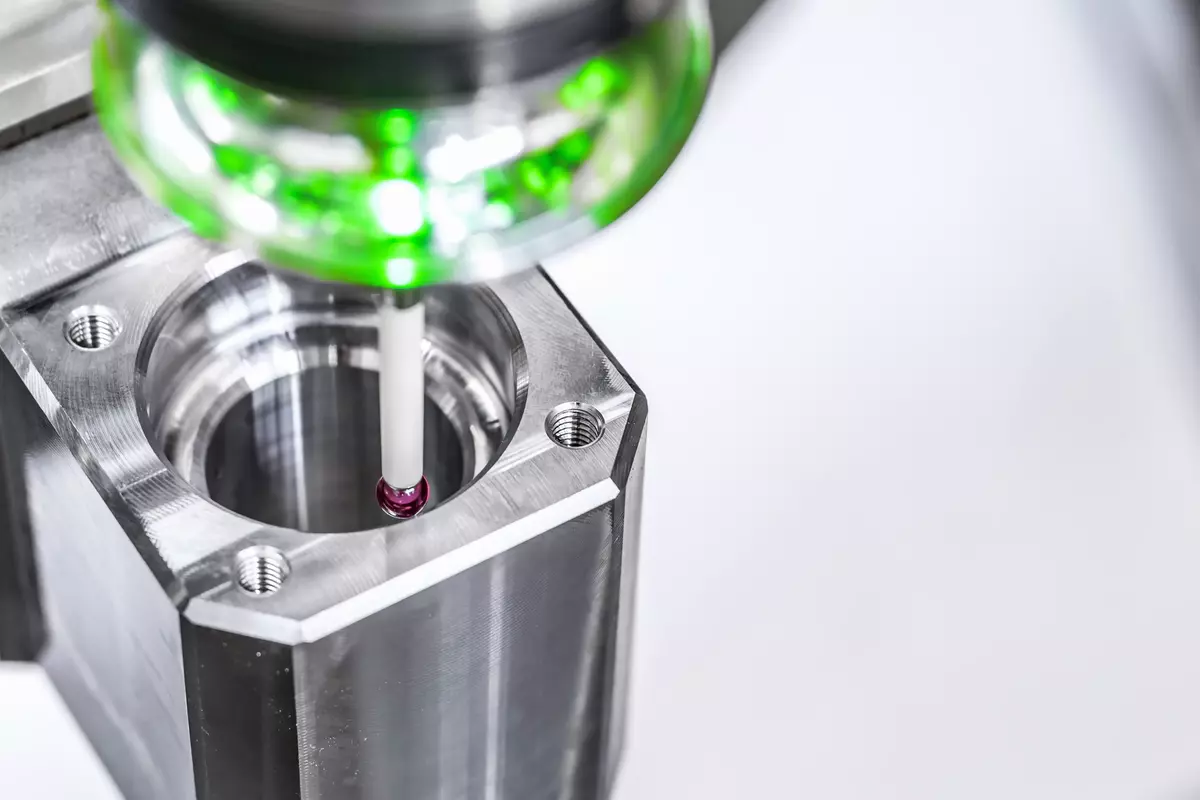

For greater precision...

Measurement systemsFor efficient oscillation mode...

Work area partitionFor up to 264 additional tool stations...

Tool cabinet magazinesFor set-up outside the machine...

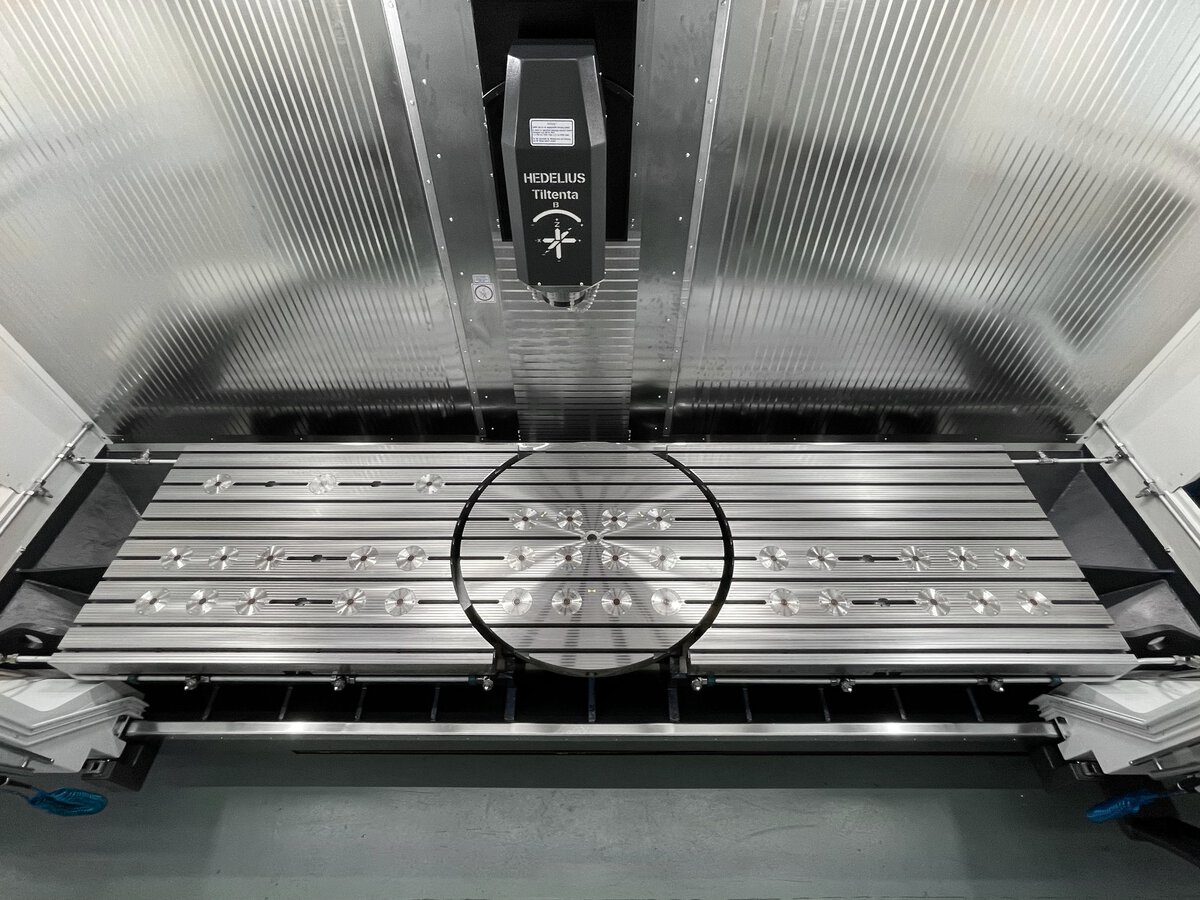

Zero-point clamping technologyFor the extension to 5-axis machining...

NC rotary tablesFor extending the range of applications...

Top-mounted rotary table and swivelling bridge

tooling optimisation