15 May 2020

Automation of machine tools taken to the next level.

Two machining centres and an automation solution.

As part of the market launch of the compact 5-axis machining centre ACURA 50, HEDELIUS is also launching the ACURA 50 EL, the automatable version of the high-performance machine for small workpieces. The North German family-owned company has focussed on an important detail that can significantly increase production efficiency.

Precision is the benchmark

As with all HEDELIUS machining centres, precision is the benchmark for the EL version of the compact ACURA 50 milling machine. Small components can be manufactured with high precision with travel paths of 500 x 550 x 550 mm (x/y/z) and a clamping weight of up to 300 kg. "The high quality of our machining centres, which also enables our customers to achieve high-precision production over the long term, has always been extremely important to us," explains HEDELIUS Managing Director Dennis Hempelmann. Among other things, the special HEDELIUS travelling column concept, in which the distance between the main spindle and the guides of the Y-axis and Z-axis always remains constant, as well as the ribbed feed carriages made of grey cast iron and the Z-axis cladded against draughts and heat radiation ensure precision. Another advantage of this design is the compactness of the ACURA 50. With a footprint of approx. 5.5 m², there is no other machining centre on the market that offers such large travel paths and a 55-position tool magazine as standard despite its compactness. The milling machine thus releases many space problems in workshops.

Two machining centres and an automation solution

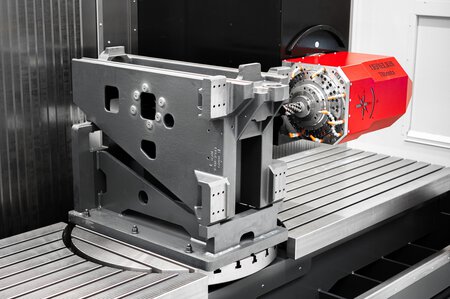

Anyone familiar with the HEDELIUS machining centres in the ACURA series will know that the ACURA 65 EL and ACURA 85 EL can be loaded from the left-hand side of the machine using automation. This is where the ACURA 50 differs from its two big sisters. It is tooling from the right-hand side of the machine through an 840 x 600 mm loading opening. This small detail has a major impact on production efficiency, as it allows two machining centres to be loaded by one robot automation system while the user always has a full view of both machines. This can lead to significant increases in productivity. At the same time, both work areas remain fully accessible so that single parts can be manufactured and inspection work can be carried out quickly and flexibly. The entire system comprising the automation solution and two ACURA machining centres is still extremely compact and requires significantly less production space than other systems.

Machining centres for automation.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?