02.07.2024

More free time: thanks to automated

CNC solutions from HEDELIUS.

Are you a machining company struggling to find qualified employees? CNC automation is your answer!

Relieve your employees of boring routine tasks - and let automation take over. Your employees deserve challenging tasks, more free time and stress-free evenings. Modern technology streamlines your processes, recognises bottlenecks at an early stage and flexibly adjusts production.

Take advantage of the benefits of CNC automation to reduce the workload on your team and stand out as an attractive employer. Invest in the future - for greater satisfaction and efficiency.

Automation concepts from HEDELIUS.

A proven concept for automation beginners offers a combination of a compact HEDELIUS 5-axis machining centre and user-friendly MARATHON automation. Our in-house pallet and workpiece handling systems are particularly advantageous for the production of repeat parts or small to medium series.

Discover solutions from HEDELIUS for a long weekend.

Highlights.

Ergonomic aspects are the top priority during the development process

Good visibility into the work area of the machining centre thanks to lateral connection of the automation

Work areas of the machining centres remain fully accessible from the front for crane loading or production of individual parts in the day shift

Intuitive operating concept with HEIDENHAINNC7

. single parts during the day shift from the front

Intuitive operating concept with HEIDENHAIN TNC7

Improved clamping through manual/pneumatic locking of the pallets

Compact design for easy integration into existing production

Solutions from our partners.

HEDELIUS not only develops its own automation solutions, but also works with numerous well-known automation partners to find the optimum solution for every need. Tailored to your individual production requirements and the needs of your employees, together we will find the right way to automate your chipping.

Discover more solutions from our partners for more leisure time.

Pallet and workpiece automation

+ Many different gripping options

+ Almost unlimited capacity

+ Refilling of blanks possible during operation

+ Variable product heights thanks to freely divisible shelving system with height control

Workpiece automation with 6-axis robot

+ Easy access

+ Protection via floor scanner or safety fence

+ Products can be stacked

+ Graphical user interface for easy retooling

Pallet handling device

+ Chaotic production of different components

+ Two storage and retrieval stations

+ Priority-controlled feeding of workpieces

Robot cell for workpiece loading

+ Many different gripping options

+ Capacity for 8 pallets or 16 pallets

+ Four to seven robust product drawers

+ Variable product heights thanks to freely divisible drawer system

TILTENTA + Automation.

Automation of swivelling spindle machining centres.

The demand for automation solutions is constantly increasing, including for the automation of our TILTENTA machining centres. In cooperation with well-known partners such as BMO and Indunorm, we offer various solutions for our swivelling spindle machining centre. HEDELIUS equips the machines with a rotary transfer, pneumatic system for controlling the zero-point clamping system, an automatic door and an interface in accordance with the requirements. The automation is realised in cooperation with our automation partners.

Pallet loading with INDUMATIK UL 300 on TILTENTA 7 NEO.

Use tooling optimisation with the INDUMATIK UL 300 on TILTENTA 7 to work more efficiently. Free up unproductive hours at night or at the weekend and benefit at the same time from the high flexibility of a swivelling spindle machining centre. The INDUMATIK UL 300 pallet magazine offers space for 8 pallets (400x400 mm) or 6 pallets (500x500 mm) with an impressive transfer weight of 300 kg. This solution has already been successfully implemented several times. Contact us for further information.

Pallet magazine INDUMATIK Robot 200 to TILTENTA 7 NEO.

With more pallets and therefore more clamping devices in the magazine, they can react more quickly to changes in production as no major retooling is required. The increased number of pallets enables continuous operation over longer periods of time without intervention by employees, for example at night or at weekends. An outstanding advantage of this solution is the extremely space-saving design thanks to the innovative SCARA construction. The flexibly extendable floor trolley means that the number of pallet locations can be expanded almost at will, and it is even possible to connect a second machine.

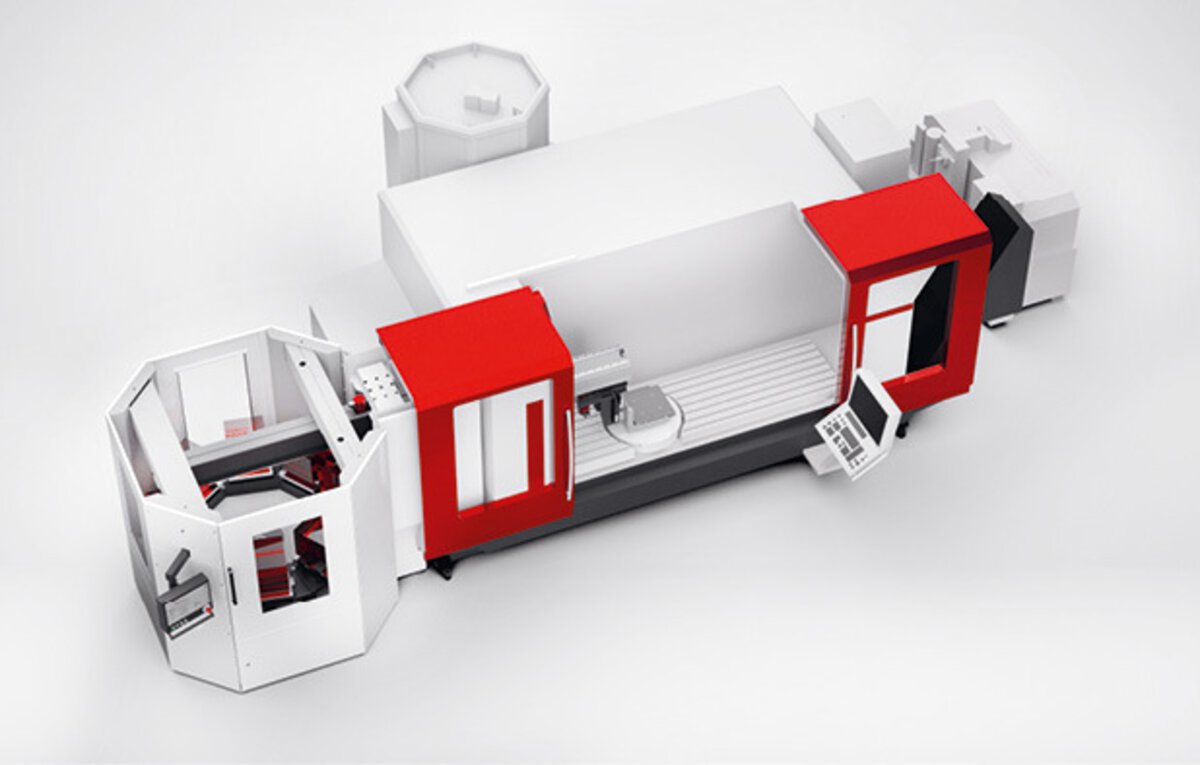

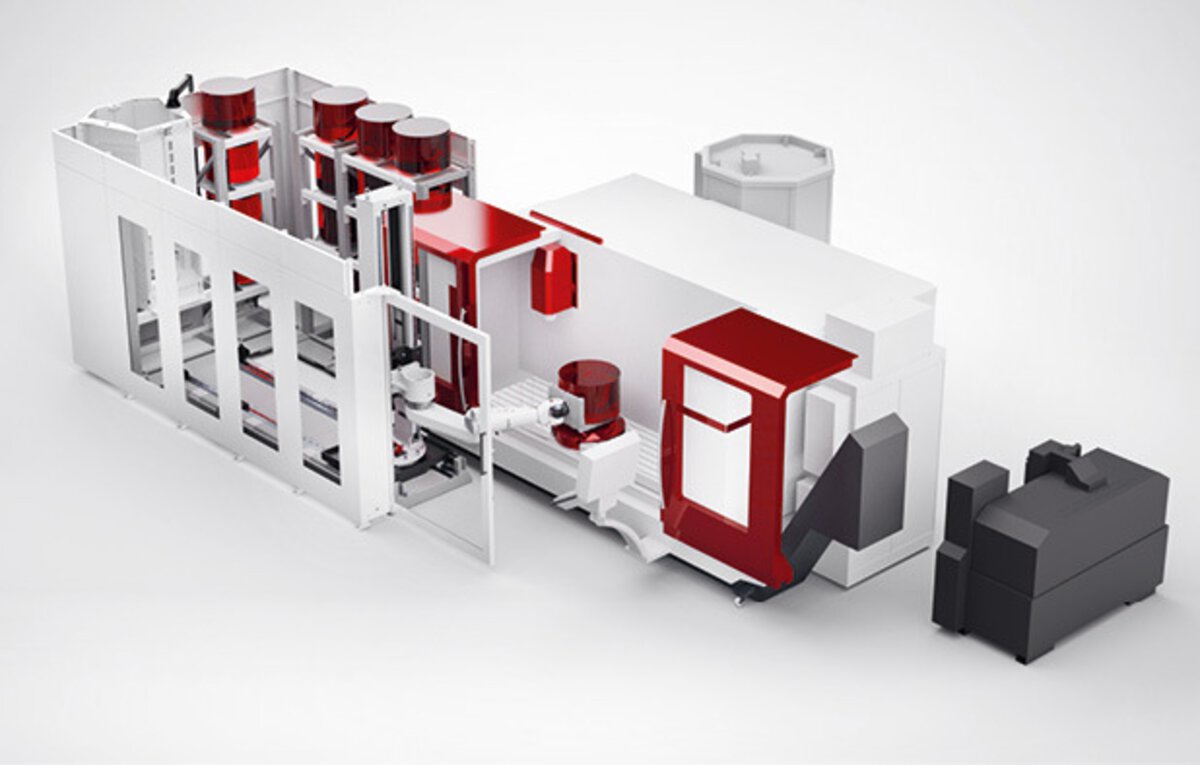

Linear concatenation.

Loading two CNC machining centres.

Whether pallet handling, workpiece handling or a combination of both - the "Twinner" concept with two ACURA 5-axis machining centres in series enables even more productivity in a small space. The ACURA machining centres can be linked in series with an INDUMATIK Light 120 and EROWA Leonardo pallet handling system or with BMO Platinum and Titanium robot cells.

Twinner with INDUMATIK Light 120.

The INDUMATIK Light 120 multi-pallet magazine can be interlinked as a pure pallet solution, with a choice of different pallet dimensions, e.g. 24 storage locations for 400 x 400 mm pallets, 30 storage locations for 320 x 320 mm pallets or 40 storage locations for 200 x 200 mm pallets. A combination of different pallet dimensions, such as 12 storage locations for 400 x 400 mm pallets and 21 storage locations for 200 x 200 mm pallets in one system, can also be realised.

Twinner with EROWA Leonardo.

The unique HEDELIUS concept with two in-line 5-axis machining centres from the ACURA 50 and ACURA 65 series, which are connected via an automation system, is becoming increasingly popular. Having already sold several systems, we are now pleased to be able to supply the first solution together with EROWA. In this case, the linking is carried out by an EROWA Leonardo pallet handling system with 24 pallets of 320 x 320 mm each.

HEDELIUS as your automation partner.

In recent years, we have developed from a manufacturer of CNC machining centres to a competent full-service provider for CNC solutions. Our extensive expertise is reflected in numerous successful automation projects that we have realised in close cooperation with our customers.

For us, the automation of your chipping is a holistic project. We support you in selecting the right automation, including live demonstrations in our technology centre. With the HEDELIUS CNC Academy, we offer training for your employees - either at your site or at our factory in Meppen. This ensures that your personnel are optimally prepared for the new production situation. Our broad and dense network of service technicians guarantees fast on-site assistance throughout Germany and ensures machine availability of 95 %.

Put your trust in HEDELIUS, your reliable partner for CNC automation.

Arrange a consultation

Our experts will be happy to support you with advice and implementation of your customised solution concept. Arrange a free consultation now and discover together with us what potential various automation solutions hold for your production.

This form requires your consent to third-party cookies. Privacy settings

Further informationMore news.

We will be on company holidays from 24 December 2025 to 2 January 2026. Please note that our customer service and sales department will only be available to a limited extent during this period. We will process your enquiries as soon as possible after our return. Further information on contact options and the availability of our customer service and sales team can be found here.

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!