12.05.2020

A little unit of normality.

300 visitors at the HEDELIUS in-house exhibition 2020.

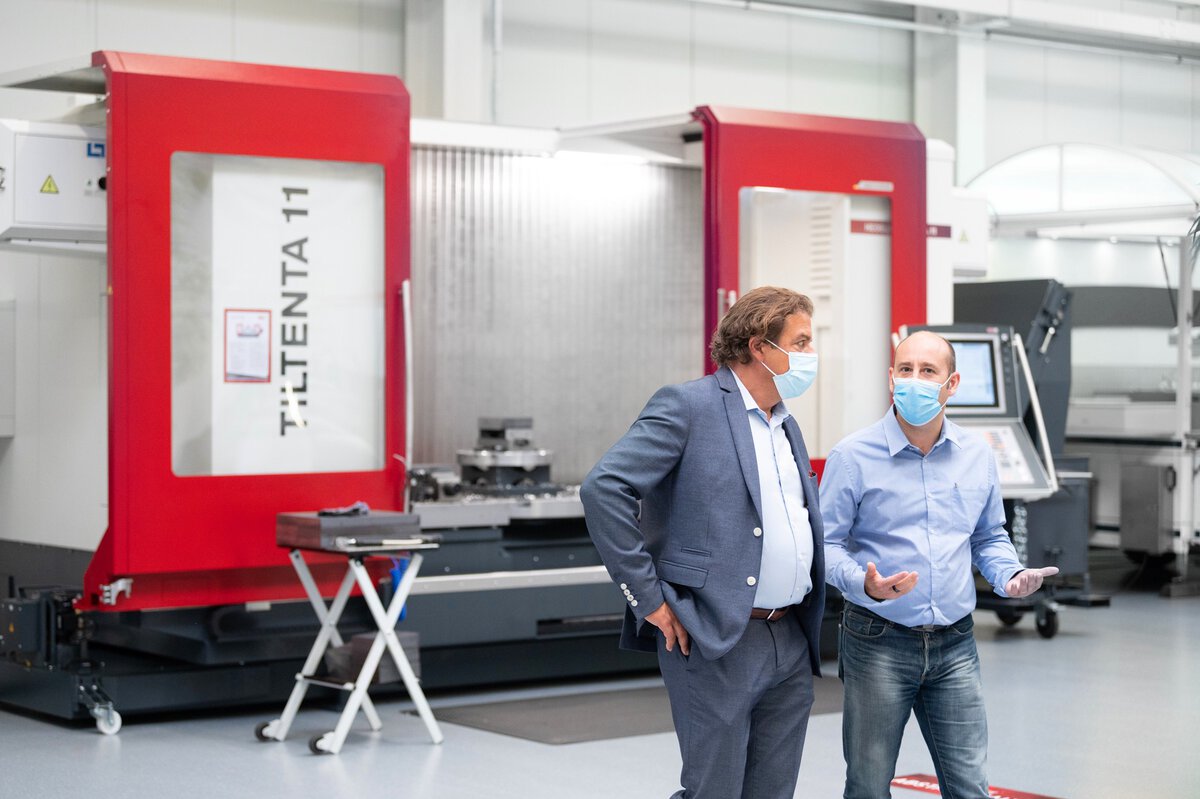

Seeing machines under chip removal, talking shop, networking - for three days, the machining centres were once again buzzing in the large demonstration centre at HEDELIUS and many of the 300 or so visitors clearly enjoyed feeling the trade fair atmosphere again after the long break due to coronavirus. "It almost felt like normality," summarised Managing Director Dennis Hempelmann. "And that's a good feeling. I would like to thank all our guests and co-exhibitors for being there."

The premiere of the in-house, highly productive MARATHON P406 automation solution for production-accompanying fixture automation in single parts or small series production was very popular. In combination with the ACURA 65 5-axis machining centre and the standby magazine as a large tool store, tooling times can be drastically reduced. In addition, the "little brother" of the MARATHON P422 shines with perfect accessibility. The six pallet locations, which are designed for a clamping weight of 250 kg each, can be rotated, which is unique in this class. HEDELIUS Maschinenfabrik is thus consistently pursuing its strategy of offering integrated in-house automation solutions.

The TWINNER concept - a linear interlinking of an ACURA 50 and an ACURA 65 with an INDUMATIK Light 120 - and automation solutions with a robot cell from BMO or a pallet magazine from EROWA also attracted a great deal of interest.

HEDELIUS sales engineer Holger Lienau showed very clearly in his presentation "Precious metal scaffolding and set-up phobia - treatment methods and successes" that automation that saves non-productive time and ensures quality is a key to higher productivity and greater economic success.

Despite the great interest in automation, visitors also focused on the wide range of possibilities offered by the TILTENTA swivelling head series machining centres and the 3-axis machines from the FORTE series. HEDELIUS had installed a total of 15 machining centres for the in-house exhibition, some with automation solutions. The offer for visitors was rounded off by an accompanying trade exhibition with well-known partner companies and guided tours of the ultra-modern HEDELIUS production facilities.

More news.

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!