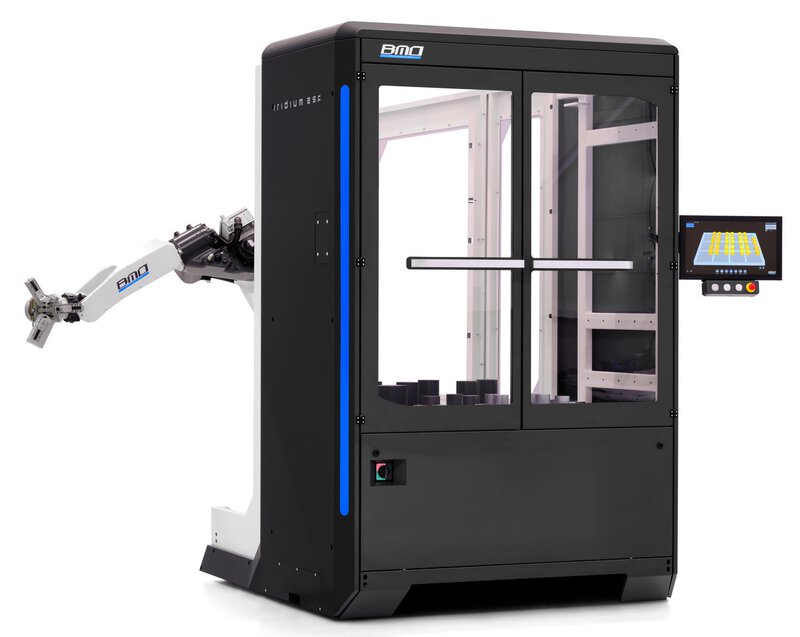

BMO Iridium Hybrid

The Iridium Hybrid from BMO combines two worlds in the automation of a CNC machining centre: flexible automation of small series using devices with pallets and series production of e.g. sawing sections by inserting workpieces directly into the machine. The Iridium impresses on the one hand with its compact dimensions of just 1,500 mm in width and on the other with a capacity of 20 pallets measuring 200 x 200 mm and a storage drawer for 50 workpieces measuring up to 100 x 100 mm.

Your advantages with the BMO IRIDIUM HYBRID

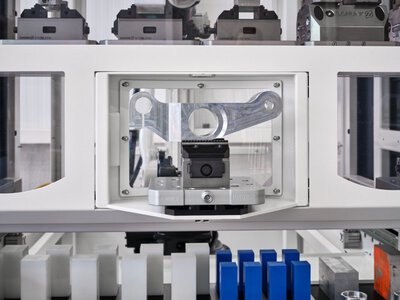

- 6-axis robot with a maximum load capacity of 25 kg

- Several product series in one production run

- Capacity for 20 pallets (200 x 200 mm)

- With a robust product drawer as standard, loadable up to 400 kg

Get the best out of your production

Greater productivity, higher delivery reliability, relieved employees: there are many good reasons for automation in production.

Maschinenvergleich.

Fügen Sie weitere Maschinen hinzu um Leistungsparameter zu vergleichen.