Measure in the machine.

Increase the accuracy of your production.

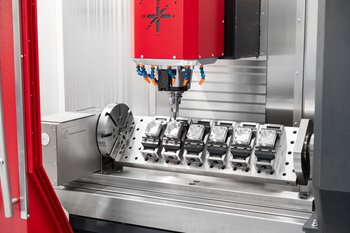

In the modern manufacturing world, sophisticated measuring systems are used for reasons of accuracy and tooling optimisation. Touch probes and lasers help to reliably ensure the quality of tools and workpieces in the chipping process. The use of such systems thus forms the basis for precise and efficient feed-through of production processes. Discover the various optional features that can help you close sources of error.

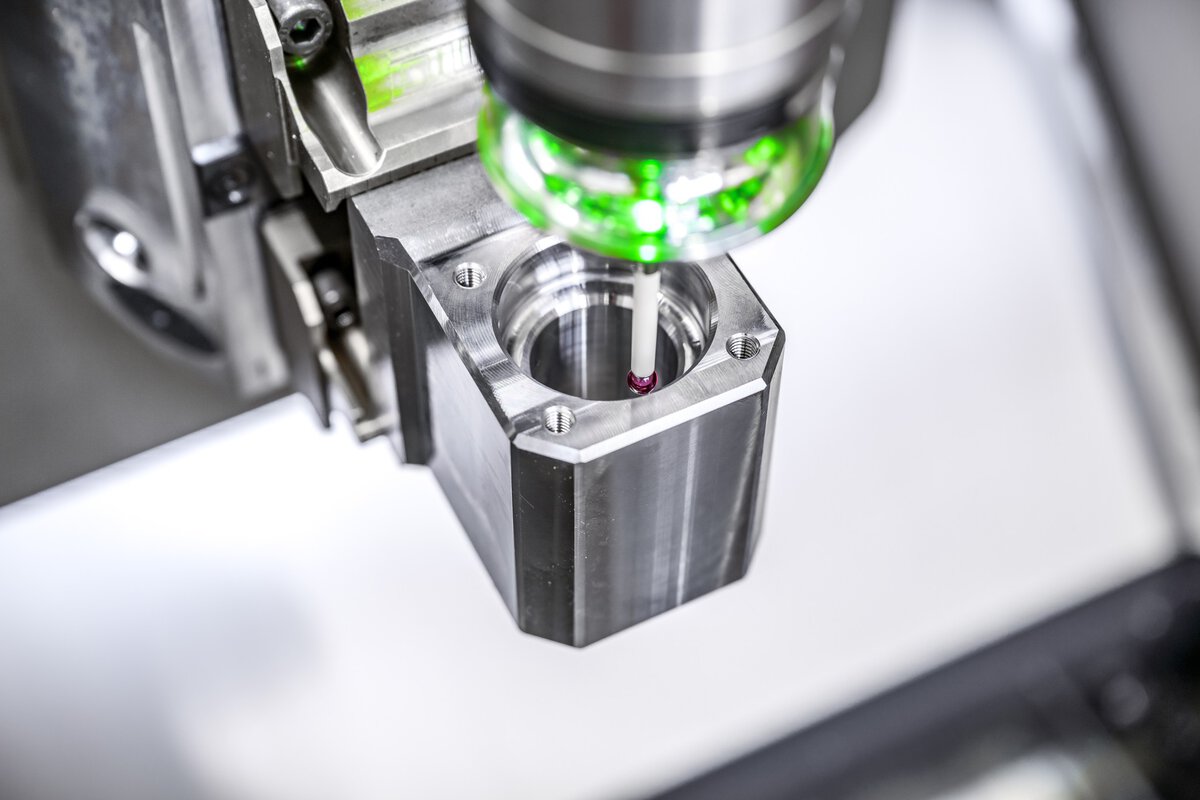

3D workpiece touch probes.

Precisely determining the position and measurements of a workpiece is essential for your production accuracy. This measurement process can be carried out automatically by a Measuring sensor, which scans the workpiece directly in the work area of your CNC machining centre. The area of application of a 3D button ranges from preparatory measurements, such as determining the allowance, to regulating measurements during chipping, such as readjusting fits, to monitoring measurements at the end of the program to create reports.

Function.

When a workpiece is approached, the stylus is deflected and a switching signal is transmitted to the control system via a precision switch. HEDELIUS uses the new bidirectional button m&h IRP 25.50 as standard. In addition to the standard 50 mm stylus, various measuring units, different extensions and stylus crosses can be used. This means that the button can be optimally adjusted to the upcoming requirements and applications in your production at any time.

Possible uses.

Determining the workpiece zero point: Quickly and accurately determine the starting point for machining, significantly reducing production time.

Determining the workpiece position: Precisely determine and correct the positioning of the workpiece to minimise machining errors.

Check measurement of workpiece dimensions: Ensuring product quality by accurately determining dimensions during the manufacturing process.

Advantages.

The future-proof IRP25.50 supports various measuring movements:

PP41.00 measuring unit with tripod system

MY21.00 measuring unit with hemisphere system

KTP44.10 temperature measuring unit

On request, we can also equip your machining centre with systems from Heidenhain, Renishaw or Blum.

Mechanical button.

As standard, HEDELIUS relies on the proven IRT35.70 infrared tool measurement system from m&h for milling machines and machining centres. The patented magnetic holder can be positioned anywhere on the machine table. Thanks to the tripod support, the system allows extremely high manual change repeat precision. The work area or chip fall is not restricted by an interfering cable. Tool measurement and tool breakage detection can therefore be carried out flexibly with just one device - even on machines with oscillating machining.

Advantages.

Positioning without tools thanks to 3-point support and magnetic holding force

Quick installation on pre-mounted base plate or directly on the machine table

No calibration required for manual repositioning

Laser measuring bridge.

Non-contact tool measurement using a laser beam not only enables precise and non-contact measurement of length and diameters, but also automatic control of tool wear or breakage. Reliable tool data is an important prerequisite for precision manufacturing. The measurement data is automatically transferred to the tool table in the control system. Here, HEDELIUS has opted for the leading technology from Blum Digilog.

Advantages.

Highly dynamic measurements of all tool characteristics

Non-contact measurement of all tool types, types, shapes and cutting materials

Detection of geometry changes such as wear on the cutting edge

Continuously good part accuracy through process-integrated temperature compensation

Reliable compensation of spindle growth and pitch circle errors

Automatic concentricity control detects poor tool fittings and contamination

Low-manning, automated operation

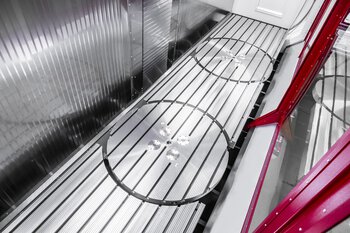

Drill breakage control.

Both the mechanical button and the laser are suitable for breakage detection. However, they require time for approach and departure, which is particularly scarce in the automated production of series. For this reason, HEDELIUS offers a fast breakage detection system for drills and taps integrated into the tool magazine in the ACURA models. After each tool change, the drill or tap is probed via a wand to check the length stored in the tool table. The measuring process only takes approx. 3 seconds and is therefore significantly faster than measuring using a button or laser.

Request for closed measuring systems.

Our experts will be happy to support you in realising your individual solution concept. Find out what potential various accessory options hold for your production and discover our advantageous probe packages. Arrange a non-binding consultation now! Use the contact form below or send us an e-mail to sales@hedelius.de.