News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

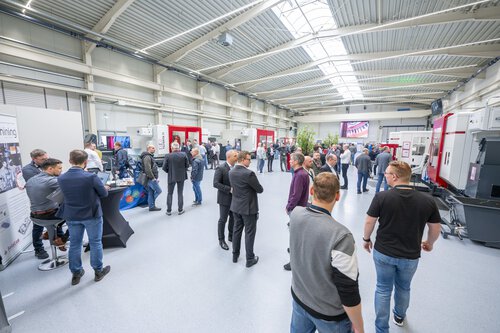

Trade fair for machining technology

14 + 15 May 2025

from 09:00 - 18:00

HEDELIUS technology centre, Meppen

Experience 13 high-performance machining centres in action at the large HEDELIUS in-house exhibition! Take the opportunity to talk to industry experts and gain valuable insights into the world of machining technology.

International Trade Fair for Machine Tools,

Manufacturing and Automation Technology

11 to 14 March 2025

Leipzig Trade Fair | Hall 2, Stand H04/I03

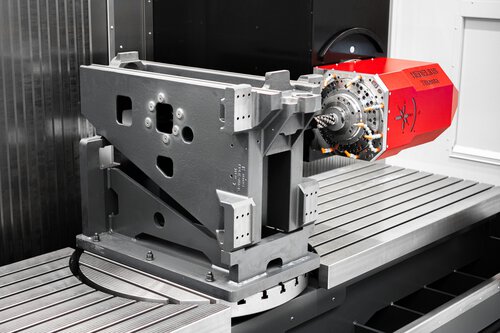

Visit our stand and discover the ACURA 65 MARATHON 5-axis machining centre with automatic loading using the MARATHON PL406 6-fold pallet magazine. Experience the system live under chip removal and get personalised advice from our experts on site. Secure your free admission ticket now!

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

In manufacturing companies that mainly produce small batch sizes, every spindle minute counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

BL Lasertechnik GmbH turned a disaster into a success story. Despite the devastating fire that destroyed its production halls, the company opted for a quick restart. Thanks to the support of partners such as HEDELIUS, production was resumed and even expanded in a very short space of time.