01.06.2024

Beginner-friendly robot automation

RoboJob Mill-Assist at the HEDELIUS technology centre

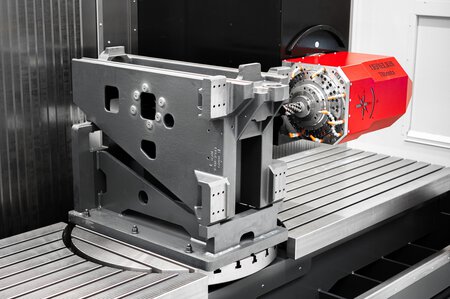

Discover our latest highlight at the HEDELIUS technology centre: the RoboJob Mill-Assist robot automation system. In conjunction with the ACURA 50 EL, this solution offers intuitive and efficient processing of small series and workpieces.

Find out more about the advantages of this automation system and how it can increase efficiency, capacity and flexibility.

We would also be happy to present this automation concept to you live.

We look forward to welcoming you to our HEDELIUS technology centre!

Technical highlights

Connected to the left-hand side of the machine, the Mill-Assist loads the machining centre through a loading opening. Thanks to the side loading, the work area remains fully available for set-up and control work, but also, for example, for single part production during the day shift. Even crane loading of the machine is possible without restrictions.

6-axis robot with 25 kg load capacity

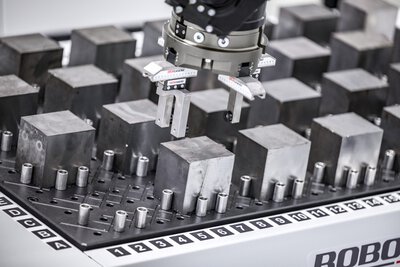

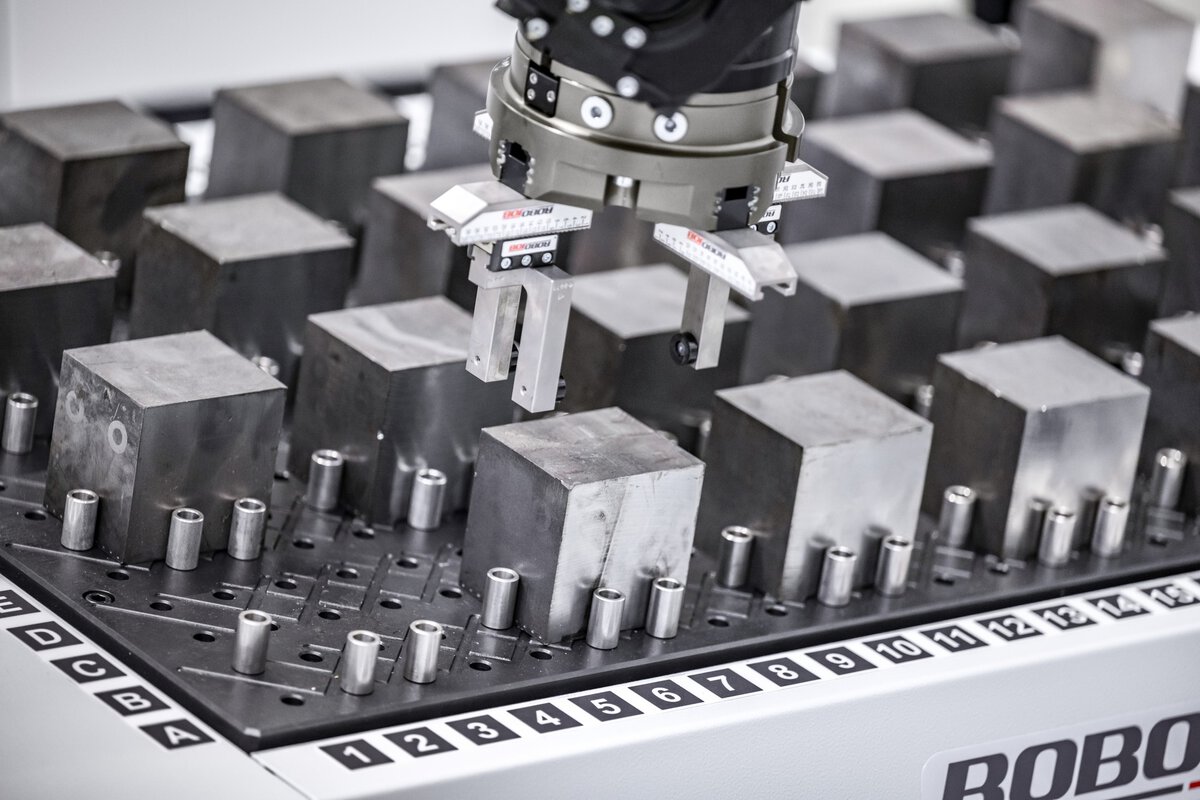

The robot arm of the Mill-Assist has a maximum transfer weight of 25 kg. The double gripper, for gripping raw and finished parts, takes the parts from the grid support and places them in the clamping device on the work table of the ACURA 50 EL. The length of the workpieces must be between 20 and 250 mm.

Graphical user interface for easy retooling

The operating panel allows the user intuitive graphical operating even without robot knowledge. Other aspects such as the clear 3D visualisations in the software and a set-up time for new workpieces of around 5 minutes round off the user-friendly operating concept. The software can also be easily supplemented with user-defined, specific optional features.

Highest capacity in the smallest space

RoboJob's patented stacking principle offers maximum capacity in the smallest of spaces. Workpieces can be stacked at a height of up to 350 mm. Grid plates are not absolutely necessary, but can be integrated if the customer so wishes. Based on this principle, a wide range of Workpiece dimensions can be loaded by the Mill-Assist.

Maximum flexibility thanks to innovative gripping system

The flexibility of the gripping system allows the user to automate a wide range of workpieces. The infeed and outfeed of the workpieces can be individually configured. A compressed air nozzle integrated into the gripper also ensures that the clamping system is cleaned before each workpiece change. The concept is rounded off by a quick and uncomplicated process for changing the grippers.

User video

Watch the video below for a brief insight into the user-friendly operating of the RoboJob Mill Assist. The changeover process on the ACURA 50, from single parts to series production, takes place in just a few simple handles.

Gallery

Arrange a demonstration appointment

Experience live

See the performance of the combination of ACURA 50 EL and RoboJob Mill-Assist for yourself and arrange a personal demonstration appointment now. You can also discover many other CNC machining centres and automation solutions that our technology centre has to offer. We look forward to seeing you here in Meppen!

More news

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?