News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

Anyone visiting WuM Werkzeug- und Maschinenbau GmbH in Mühlhausen, Thuringia, will get an impression of the end products that are manufactured using their tools from the entrance lobby. WuM machines high-precision stamping tools for the automotive industry on a TILTENTA 7, an ACURA 85 and a FORTE 11.

For three days, HEDELIUS and 22 trade exhibitors presented innovative machining solutions on 2200 square metres of exhibition space, including various automation solutions for small and medium-sized metalworking companies with batch sizes from 1 to 500.

Lang Technik GmbH from Holzmaden delivered its ROBOTREX 96 automation solution to Meppen just in time for the in-house exhibition. The automation cell consists of a FANUC 6-axis robot with a payload capacity of 50 kg and two automation trolleys, tooling with a total of 46 vices.

Today, a machining centre must not only work quickly, precisely and reliably, but also look good. HEDELIUS therefore offers a paint finish for the work area doors of all machines according to your colour requirements.

Whether workpiece set-up, tool set-up, programming or maintenance - the focus is always on convenience, safety and productivity in your production. A clear operating and maintenance concept with good accessibility to all working ranges and optimally arranged control elements make daily work easier.

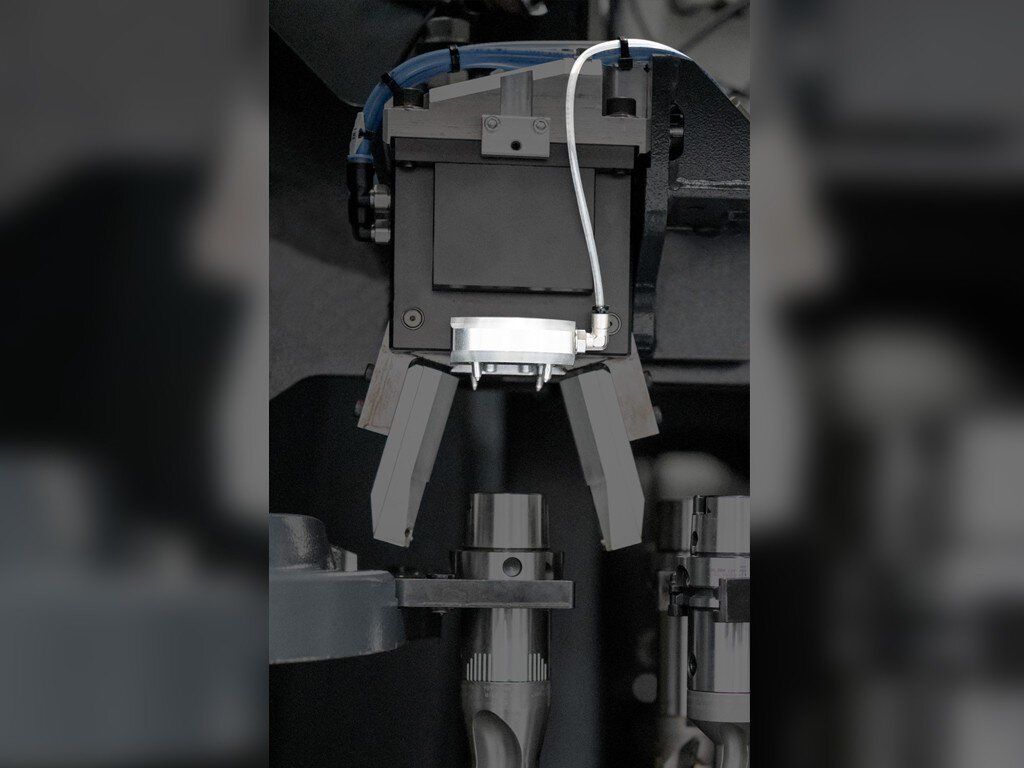

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.

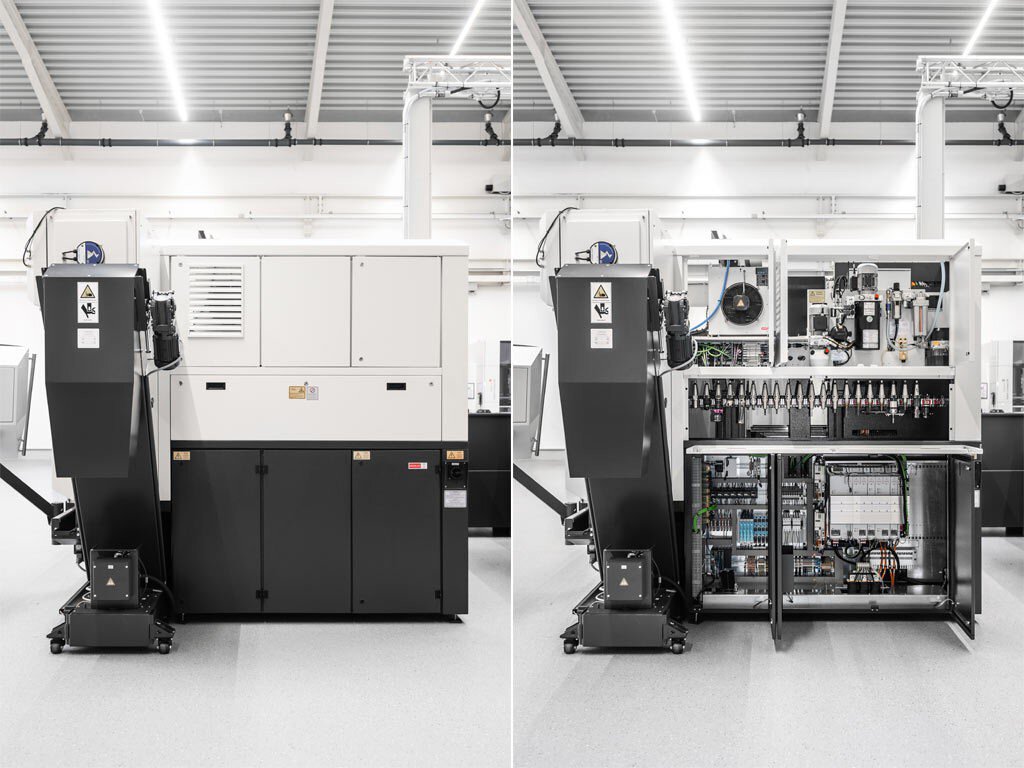

HEDELIUS Maschinenfabrik has once again received an order to supply two automated 5-axis machining centres from the ACURA series. The automation is realised by an EROWA ERD 250 linear robot. The entire system is 20 metres long and has 73 pallet stations and 520 tool stations.

With this certificate, Creditreform Leer once again attests to the company's excellent creditworthiness. The company continues to fulfil the high requirements for an extension of the CrefoZert in full. Compared to the previous year, the creditworthiness index was even slightly improved from 108 to 106.

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.