20 February 2023

HEDELIUS continues to expand its site in Meppen.

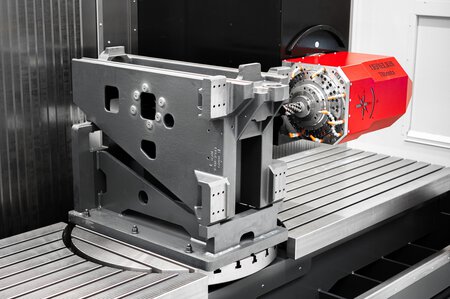

Chip for state-of-the-art TILTENTA factory.

The earthworks for the construction of a new production hall for HEDELIUS Maschinenfabrik have begun. On a 25,000 square metre site, around 500 metres as the crow flies from the company headquarters in the Meppen-Nödike industrial estate, a state-of-the-art factory for the production, assembly and storage of the TILTENTA series is being built on a total of 10,000 m² under roof. Completion is planned for spring 2024.

The versatile TILTENTA swivelling head machining centre in particular is enjoying unbroken demand on the market, which is now to be met with the expansion. "The aim is to significantly increase our delivery capacities in the coming years and further optimise processes," explains HEDELIUS Managing Director Dennis Hempelmann. A glance at the production and storage areas reveals a planned increase of a considerable 40 per cent.

The TILTENTA series is thus representative of HEDELIUS' continued solid economic development: in 2022, turnover increased by 11 per cent compared to the previous year to just under EUR 70 million. Thanks to well-filled order books, the company is targeting further growth for the current year.

HEDELIUS is also clearly on the lookout for new staff, particularly in the design and assembly ranges. Anyone interested can find an overview of all open positions at hedelius.de/karriere.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?